Non-hot processing method for zongzi leaves

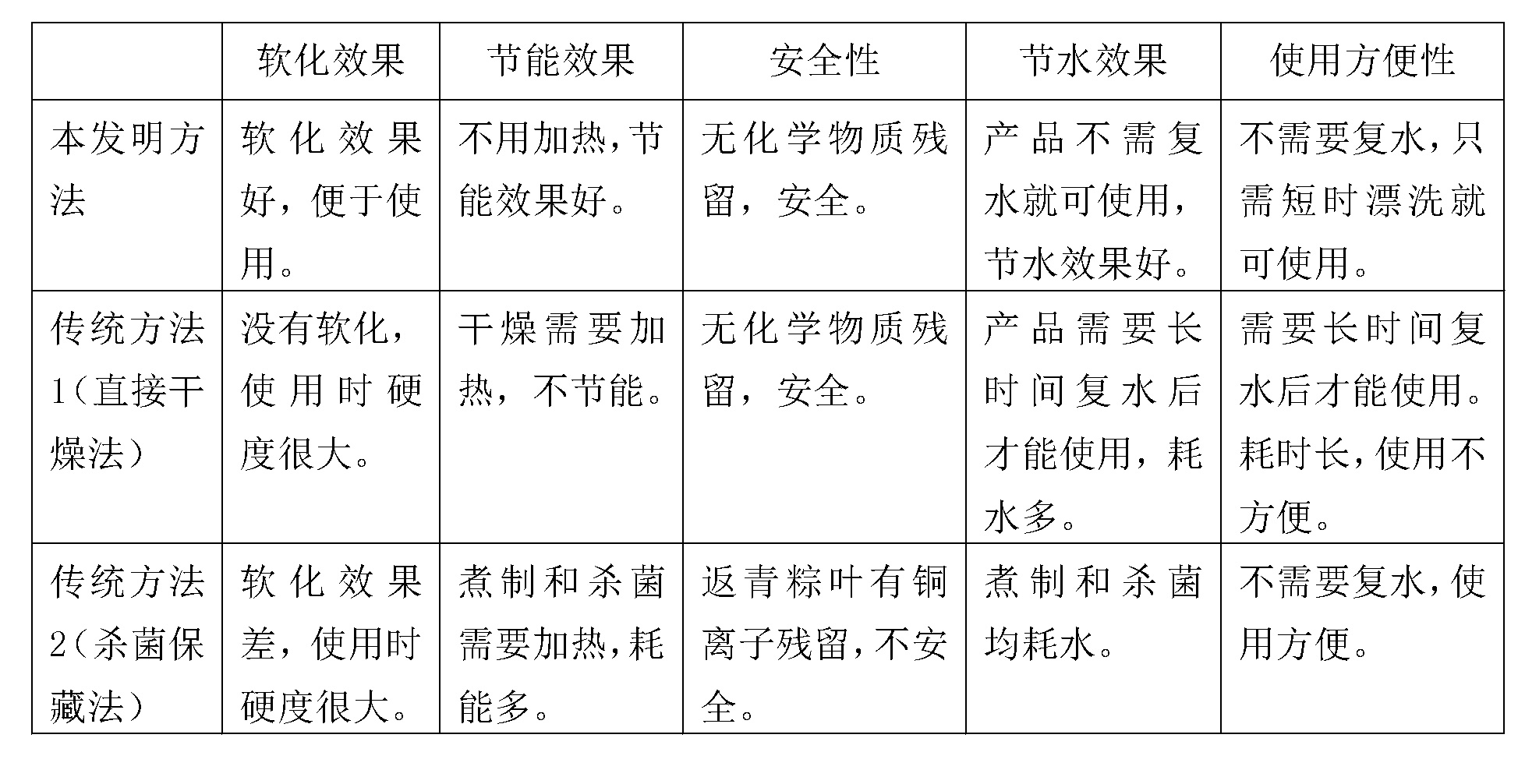

A technology of non-thermal processing and zong leaves, applied in the field of zong leaves processing that does not require heating and energy consumption, can solve the problems of food safety hazards, inconvenient use, high cost, etc., and achieve the effects of reducing production costs, convenient use, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take fresh Ruo bamboo leaves that have fully grown up but have not yet formed an obvious wax layer, and soak the Ruo bamboo leaves in hydrogen Sodium oxide aqueous solution to dewax and soften, and make the dirt on the blade surface fall off for easy cleaning. So soaked for 30 days. Take out the bamboo leaves and rinse the surface dirt with clean water. The used sodium hydroxide aqueous solution continues to be used for the treatment of the next batch of raw materials after concentration adjustment. Drain the cleaned Ruo bamboo leaves and pickle them layer by layer with salt: put the Ruo bamboo leaves in layers in the cement pool, each layer is less than 1 cm thick, place one layer, press it tightly, Sprinkle a layer of salt between the two layers of bamboo leaves (the amount of salt for each layer is the total amount of salt divided by the number of layers of bamboo leaves). So until it is packed near the mouth of the pond, the top layer is the salt layer, and the t...

Embodiment 2

[0026] Take fresh Ruo bamboo leaves that have fully grown but have not yet formed an obvious wax layer. According to the weight ratio of the added Ruo bamboo leaves to the 4% mass concentration of sodium hydroxide aqueous solution is 6:4, the Ruo bamboo leaves are soaked in the sodium hydroxide aqueous solution to play the role of dewaxing and softening, and make the leaves Dirt on the surface comes off for easy cleaning. Do this for 40 days. Take out the bamboo leaves and rinse the surface dirt with clean water. The used sodium hydroxide aqueous solution continues to be used for the treatment of the next batch of raw materials after concentration adjustment. Drain the cleaned Ruo bamboo leaves and pickle them layer by layer with salt: put the Ruo bamboo leaves in layers in the cement pool, each layer is less than 1 cm thick, place one layer, press it tightly, Sprinkle a layer of salt between the two layers of bamboo leaves (the amount of salt for each layer is the total am...

Embodiment 3

[0028] Take fresh Ruo bamboo leaves that have fully grown but have not yet formed an obvious wax layer. According to the weight ratio of the added Ruo bamboo leaf and the sodium hydroxide aqueous solution of 5% mass concentration is the ratio of 7:3, the Ruo bamboo leaf is soaked in the sodium hydroxide aqueous solution, plays the effect of dewaxing and softening the Ruo bamboo leaf, And make the dirt on the surface of the blade fall off for easy cleaning. Do this for 60 days. Take out the bamboo leaves and rinse the surface dirt with clean water. The used sodium hydroxide aqueous solution continues to be used for the treatment of the next batch of raw materials after concentration adjustment. Drain the cleaned Ruo bamboo leaves, and press the Ruo bamboo leaves into 56% saline solution for 360 days according to the weight ratio of Ruo bamboo leaves and salt water: 1:1. The used saline solution, after concentration adjustment, continues to be used for the preservation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com