Joint production method and production device of dilute nitric acid and concentrated nitric acid

A technology of joint production and concentrated nitric acid, applied in the field of production equipment, joint production of dilute nitric acid and concentrated nitric acid, can solve problems such as equipment manufacturing, maintenance, use, control and safety difficulties, increase production and operation costs, increase operation and maintenance personnel, etc., To achieve the effect of reducing investment in production equipment, reducing construction area and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate the understanding of the present invention, the embodiments of the present invention are further described below with reference to the accompanying drawings. It should be noted that the present invention cannot be limited to the above-mentioned conditions due to the specific description of the embodiment, and those skilled in the art can make no difficult adjustments to the embodiment of the present invention based on the content of the embodiment and using their professional knowledge All changes and obvious changes shall be included within the protection scope of the present invention.

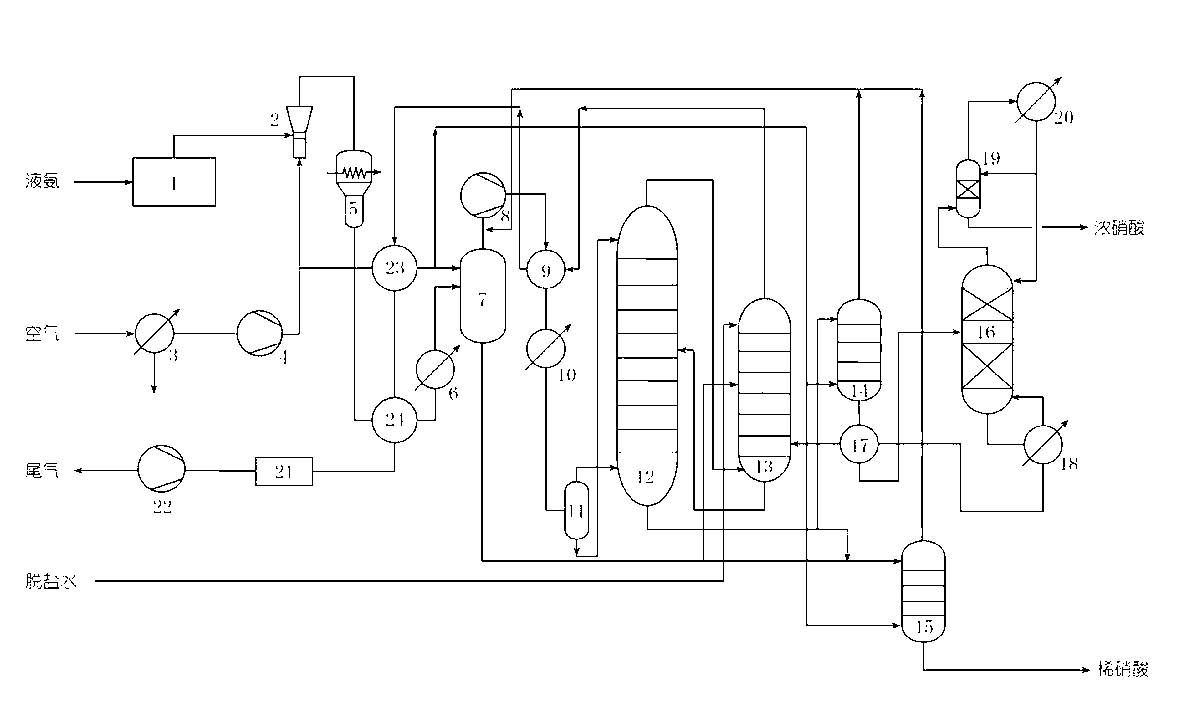

[0044] The technological process of the combined production method of dilute nitric acid and concentrated nitric acid is as follows figure 1 As shown, it consists of three parts: oxidation, absorption and distillation.

[0045] Oxidation process.

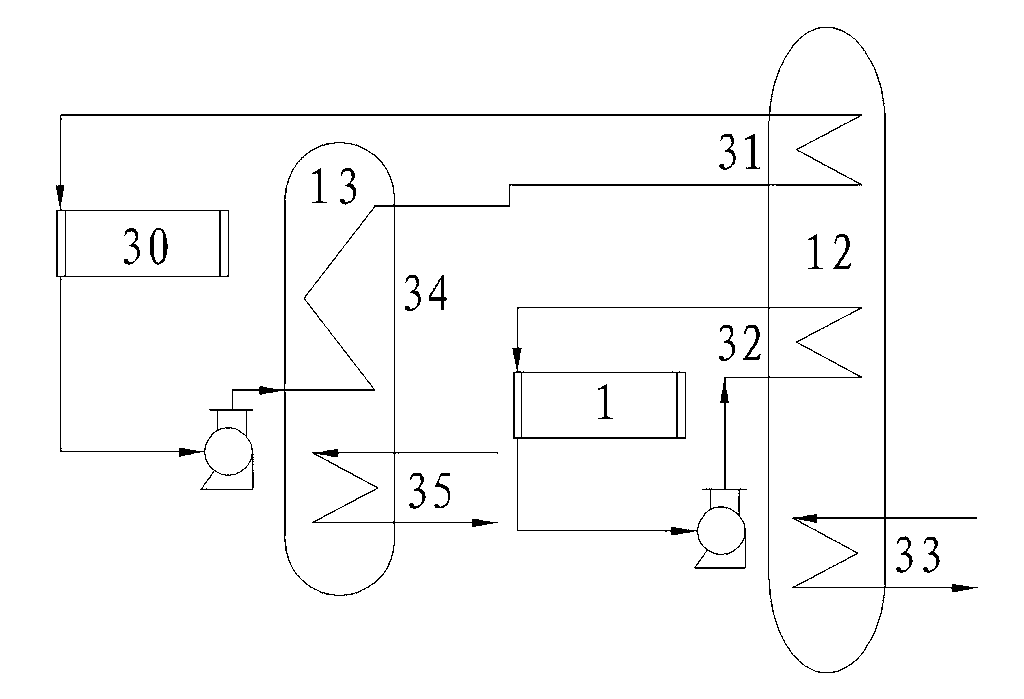

[0046] Liquid ammonia is sent into the ammonia evaporator 1, and the closed circulating water circulated between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com