High-strength alkali-resisting castable for preparing coal gangue, and method thereof

A technology for coal gangue and castables, applied in the field of refractory castables, can solve problems such as poor alkali resistance, achieve the effects of low porosity, prevent alkali cracking, and reduce consumption

Active Publication Date: 2014-09-03

TONGDA REFRACTORY TECH CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is a high-strength alkali-resistant castable prepared from coal gangue and its method. Since the silicon content in coal gangue is relatively high, it can improve the shortcomings of poor alkali resistance of the bauxite aggregate in the current alkali-resistant castable, thereby improving the alkali resistance. Alkali resistance of alkali castables

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The following examples illustrate the implementation and characteristics of the present invention, but the present invention is not limited to the limitations of the following examples.

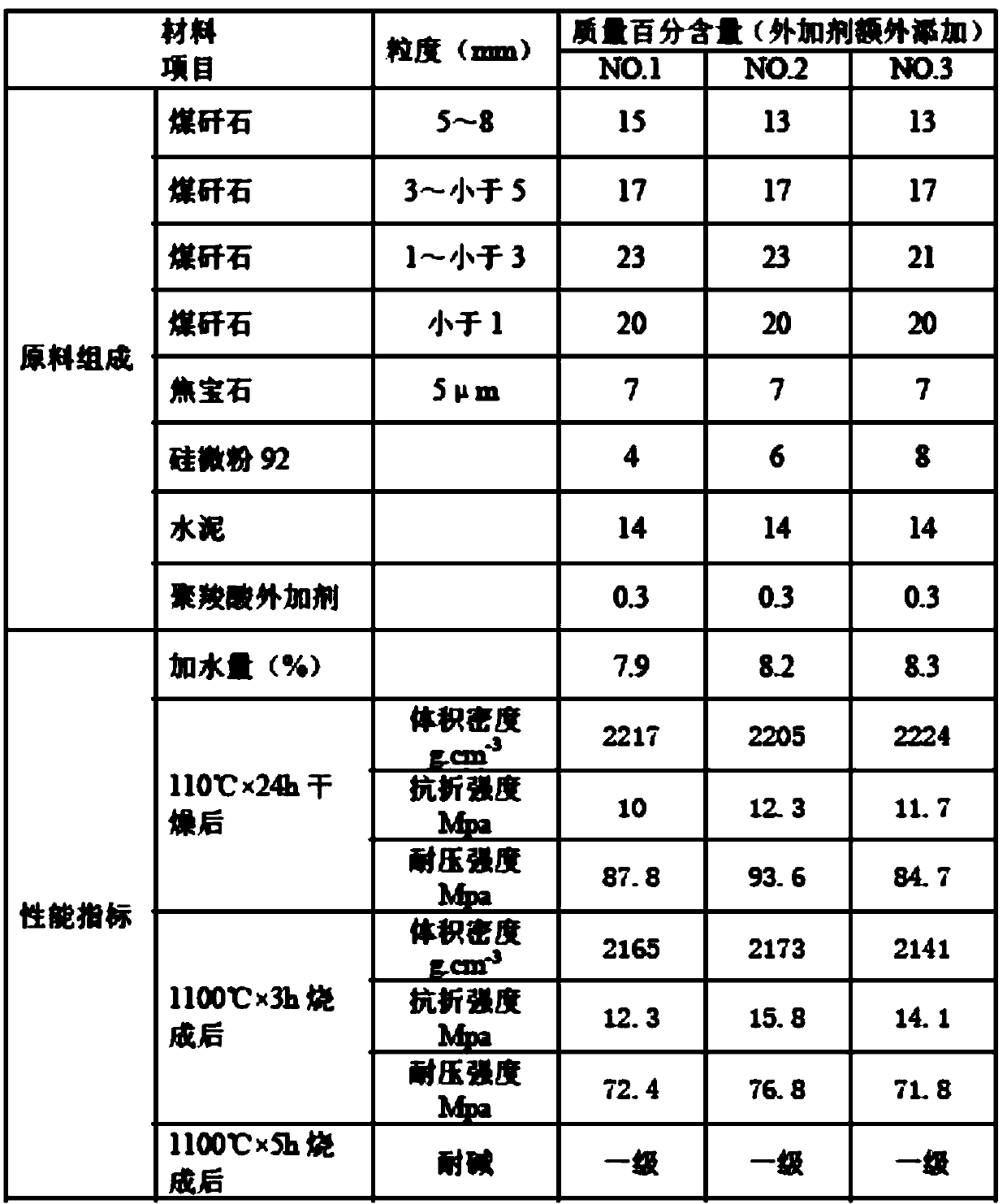

[0018] See Table 1 for implementation

[0019] Table 1 Embodiments of the present invention

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

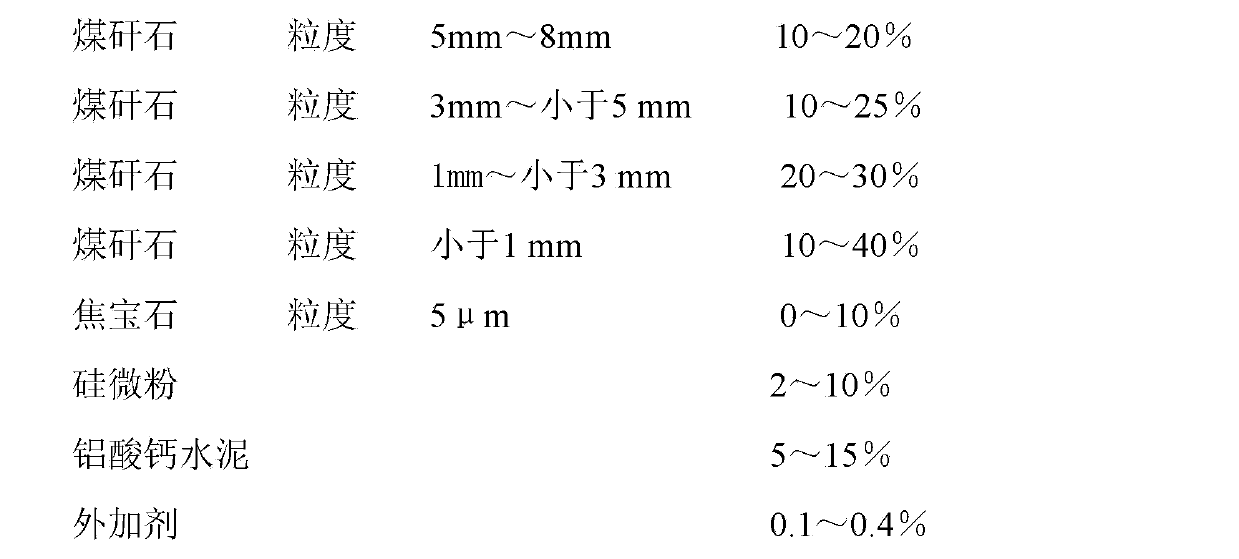

A high-strength alkali-resistant castable prepared from coal gangue and a method thereof belong to the technical field of refractory castables. It is composed of coal gangue, silicon micropowder, coke gemstone micropowder, calcium aluminate cement, and admixtures. The particle size and mass percentage of each raw material are: coal gangue: 10% to 20% of particle size 5mm ~ 8mm, coal gangue: particle size 3mm ~ less than 5mm 10-25% of coal gangue: 20-30% of particle size 1mm-less than 3mm, coal gangue: 10-40% of particle size less than 1mm, burnt gem: 0-10% of particle size 5μm, silicon powder: 2-10% , Calcium aluminate cement: 5-15%, admixture: 0.1-0.4%. The invention has the advantages of fully utilizing the waste coal gangue resources, and the high SiO2 content in the coal gangue can prepare high-strength alkali-resistant castables with excellent alkali resistance and low price. This kind of castable can be widely used in the preheater and grate cooler of the new dry process cement rotary kiln system, where the alkali erosion is relatively serious and the thermal engineering is similar.

Description

technical field [0001] The invention belongs to the technical field of refractory castables, and in particular provides a high-strength alkali-resistant castable prepared from coal gangue and a method thereof. Background technique [0002] From the late 1990s to the present, China's new dry process cement production has developed rapidly, especially large-scale new dry process cement kilns, such as new dry process cement production technology and equipment with a daily output of 5,000 tons and a daily output of 10,000 tons have reached the international advanced level. my country has become the world's cement manufacturing center. [0003] With the improvement of production technology, the overproduction phenomenon of cement clinker production line is more and more common, which brings a series of influences to dry process cement production line. For example, the alkali enrichment and alkali erosion of the castables in the preheater, grate cooler and kiln hood are becoming m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/66

Inventor 罗华明赵燕李晓枫陈庆帅惠飞王振永姚维东

Owner TONGDA REFRACTORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com