Method for uniformly colorizing fish flesh

A kind of fish meat, uniform technology, applied in application, food preparation, food science and other directions, can solve the problems of long time and complicated operation, and achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

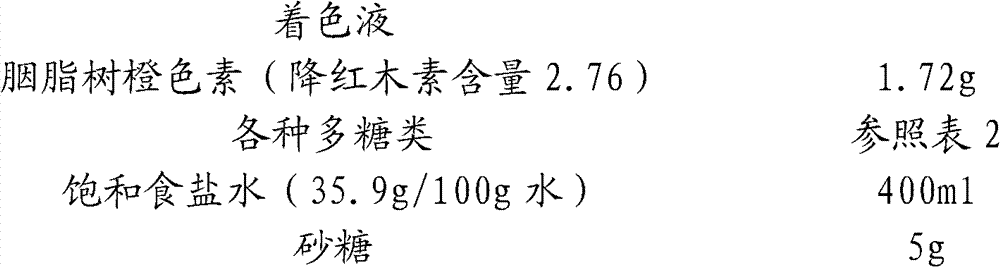

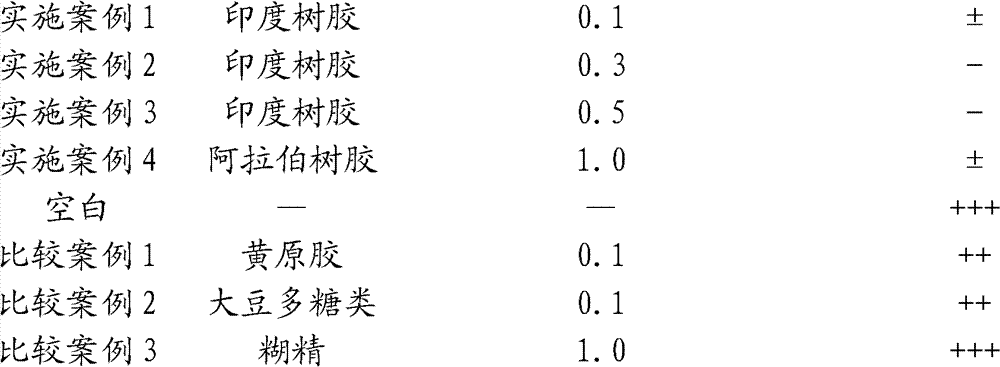

Method used

Image

Examples

experiment example 2

[0033] Experimental Case 2 Discussion on Pigments

[0034] Pigments other than annatto are used to color salmon flesh when gum ghatti or gum arabic is not used. The specific method is: in 400ml saturated salt water (35.9g / 100g water), add 5g granulated sugar and make it dissolve, then add various pigments as shown in Table 3 and stir to prepare the coloring solution. When the weight ratio of the coloring solution to the salmon meat is 4:1, soak the salmon meat in the coloring solution, soak for 40 hours at a refrigerated temperature of 5°C, and then evaluate whether there are spots or stains .

[0035]

[0036] Using beet red pigment, capsanthin, carotene, and curcumin to color the salmon meat in Experimental Cases 3-7, even if Indian resin or Arabic resin is not used, spots and stains will not occur, and the coloring will be uniform. However, in the coloring of the salmon flesh of Experimental Cases 1 and 2 using cochineal red pigment or monascus red pigment, spots and s...

experiment example 3

[0037] Experimental case 3 Coloring of salmon meat (2)

[0038]In Experimental Case 2, cochineal red pigment or monascus red pigment, which can generate spots and stains, is used to color salmon meat as in Experimental Case 1 and Implementation Case 3. The specific method is: dissolve granulated sugar in saturated saline, add Indian resin, and stir to dissolve. Thereafter, carmine and monascus red pigments were respectively added and stirred for 15 minutes. When the weight ratio of the solution to the salmon meat is 4:1, the salmon meat is soaked in the solution and soaked for 40 hours at a refrigeration temperature of 5° C. to color the salmon meat. (implementation case 5 uses cochineal red pigment, and implementation case 6 uses monascus red pigment). In the implementation case 5 and the implementation case 6, the salmon meat used cochineal red pigment and monascus red pigment, no spots and stains were formed, and the color was uniform.

experiment example 7

[0039] Experimental case 7 Coloring of salmon meat (3)

[0040] The addition of gum arabic in experimental case 1, implementation case 4 is increased to 5%, carries out the coloring experiment (implementation case 7) of the same salmon meat of experiment case 1, result: used annatto pigment, does not have The generation of blemishes and pigmentation, uniform coloring.

[0041] The fish meat is soaked in a solution containing one or more of annatto, cochineal and monascus red pigments, and at the same time, gum ghatti or gum arabic is added to the solution. Although this coloring process is simple, it provides uniformly colored fish flesh free from spots and stains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com