Coal tar hydrodemetallization catalyst and preparation method thereof

A hydrodemetallization and catalyst technology, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem that catalyst pores cannot be fully utilized and accelerate catalyst deactivation. Speed, carrier pore distribution and dispersion, etc., to achieve the effect of shortening the operation cycle, improving the capacity of metal impurities, and reducing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

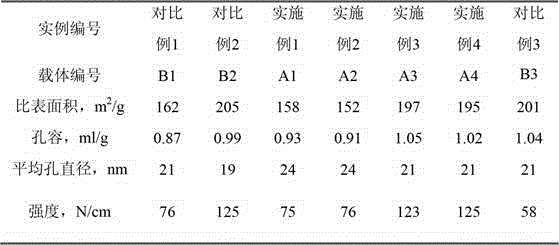

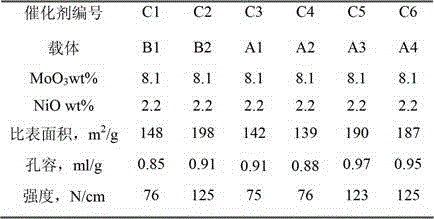

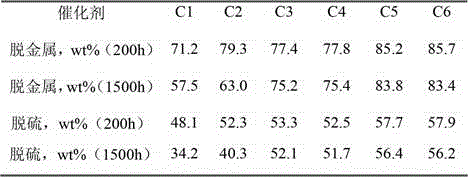

Embodiment 1

[0037] The alumina carrier B1 is modified. The treatment process is: oxalic acid solution (pH value lower than 1) with an organic acid solution concentration of 1mol / L, the treatment time is 0.5 hours, and the treatment temperature is 40°C. The volume ratio of the dosage to the alumina carrier is 5:1. After the organic acid solution is treated, drain the organic acid solution, dry at 120°C for 3 hours, then impregnate the aluminum nitrate solution, use saturated impregnation, the concentration of the aluminum nitrate solution is 3mol / L, dry at 150°C for 3 hours, and roast at 450°C for 2 hours. hours, the modified alumina carrier A1 was obtained.

Embodiment 2

[0039] The alumina carrier B1 is modified, the treatment process is: acetic acid solution (pH value lower than 2) with an organic acid solution concentration of 3mol / L, the treatment time is 2 hours, the treatment temperature is 15°C, and the amount of the organic acid solution is The volume ratio of the volume meter to the alumina carrier is 8:1. After the organic acid solution is treated, drain the organic acid solution, dry at 120°C for 3 hours, then impregnate the aluminum nitrate solution, use saturated impregnation, the concentration of the aluminum nitrate solution is 5mol / L, dry at 150°C for 3 hours, and roast at 450°C for 2 hours. hours, the modified alumina carrier A2 was obtained.

Embodiment 3

[0041] The alumina carrier B2 is modified. The treatment process is: citric acid solution (pH value lower than 1) with an organic acid solution concentration of 2mol / L. The treatment time is 1 hour, the treatment temperature is 20°C, and the amount of organic acid solution is The volume ratio to the alumina carrier is 3:1 by volume. After the organic acid solution is treated, drain the organic acid solution, dry at 120°C for 3 hours, then impregnate the aluminum nitrate solution, use saturated impregnation, the concentration of the aluminum nitrate solution is 2mol / L, dry at 150°C for 3 hours, and roast at 450°C for 2 hours. hours, the modified alumina carrier A3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com