Combined central body cavitating nozzle

A central body and combined technology, which is applied in the direction of injection devices, injection devices, chemical instruments and methods, etc., can solve the problems of discontinuous cavitation jet, inconspicuous cavitation effect, small stagnation area, etc., to achieve erosion and strong blow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

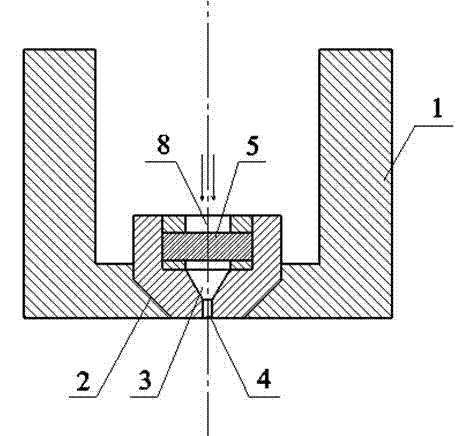

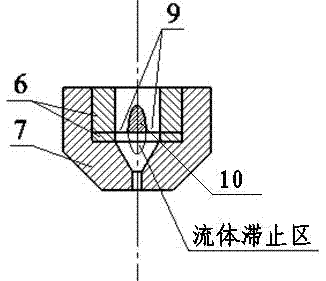

[0012] There is a nozzle jacket 1 connected to the high-pressure system, and the center body 5 is in the shape of a semi-elliptical column. In order to enhance interchangeability, a center body fixing seat 6 is provided. In order to facilitate processing, the fixing seat is divided into upper and lower parts and processed separately. The two parts The inner and outer diameters are the same, the thickness of the lower part is 1 to 3 mm, and the upper part is provided with two oval holes symmetrically along the bottom surface, so that the nozzle can be installed, and the two parts of the fixing seat and the central body are fixed with glue. The central body 5 is horizontally placed on the central body fixed seat 6 perpendicular to the axial direction of the fixed seat. The gap between the central body fixed seat 6 and the central body is a flow passage 9, and the upstream section 8 of the central body is facing the direction of the incoming flow. Place the central body fixing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com