Method for preparing titanium tetrafluoride

A technology of titanium tetrafluoride and fluorine gas, applied in the direction of titanium halide, etc., can solve the problems of difficult separation and purification, serious equipment corrosion, environmental pollution, etc., and achieve the effects of stable product quality, low environmental pollution, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

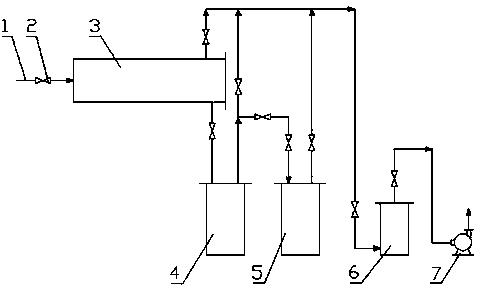

[0043] First, clean and dry the reactor 3, add 2 kg of titanium metal with a purity of 98.5% into the reactor 3, close the reactor 3, and evacuate it to -0.10MPa (gauge pressure), and after the leak test of the reactor 3 is qualified, remove it Preheat to 100°C.

[0044] Secondly, slowly open the fluorine gas inlet valve 2 in front of the reactor 3, and feed fluorine gas with a purity of 96% into the reactor 3, so that the fluorine gas and metal titanium are contacted in the reactor 3 to undergo a synthesis reaction to generate gaseous tetrafluoride. For the crude titanium product, the reaction process pressure is -0.05MPa, and the temperature in the reactor 3 is 200°C.

[0045] Again, the gaseous titanium tetrafluoride from the reactor 3 enters the purifier 4, the temperature inside the purifier 4 is 150° C., and the gauge pressure inside the purifier 4 is -0.10 MPa.

[0046] Finally, 4.0 kg of crude gaseous titanium tetrafluoride was collected in the purifier 4. The te...

Embodiment 2

[0048] First, the reactor 3 is cleaned and dried, 2 kg of titanium metal with a purity of 98.5% is added to the reactor 3, the reactor 3 is sealed, and the gauge pressure is evacuated to -0.09MPa. Heat to 150°C.

[0049] Secondly, slowly open the fluorine gas inlet valve 3 in front of the reactor 3, and feed fluorine gas with a purity of 96% into the reactor 3, so that the fluorine gas and metal titanium are contacted in the reactor 3 to undergo a synthesis reaction to generate gaseous tetrafluoride. Titanium crude product, the reaction process pressure is 0MPa, and the temperature of reactor 3 is 310°C.

[0050] Again, the titanium tetrafluoride coming out of the reactor 3 enters the purifier 4, the temperature inside the purifier 4 is 200°C, and the internal surface pressure of the purifier 4 is -0.05MPa.

[0051] Finally, 4.7 kg of crude gaseous titanium tetrafluoride was collected in purifier 4. Cool the temperature in the purifier to normal temperature, condense the gas...

Embodiment 3

[0053] First, the reactor 3 is cleaned and dried, 2 kg of titanium metal with a purity of 98.5% is added to the reactor 3, the reactor 3 is sealed, and the gauge pressure is evacuated to -0.08MPa. Heat to 200°C.

[0054] Secondly, slowly open the fluorine gas inlet valve 2 in front of the reactor 3, and feed fluorine gas with a purity of 96% into the reactor 3, so that the fluorine gas and metal titanium are contacted in the reactor 3 to undergo a synthesis reaction to generate titanium tetrafluoride For the crude product, the gauge pressure during the reaction was 0.05MPa, and the temperature in the reactor 3 was 500°C.

[0055] Again, the gaseous titanium tetrafluoride from the reactor 3 enters the purifier 4, the temperature inside the purifier 4 is 280° C., and the gauge pressure inside the purifier 4 is 0 MPa.

[0056] Finally, 4.5 kg of crude gaseous titanium tetrafluoride was collected in the purifier 4. Cool the temperature in the purifier to normal temperature, cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sublimation point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com