Safety pre-warning system of mining equipment

A technology of safety early warning system and mining equipment, applied in mining equipment, mining equipment, instruments, etc., can solve problems affecting production safety, short-circuit explosion flammable gas, sensitive contacts and connection points, etc., and achieve reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

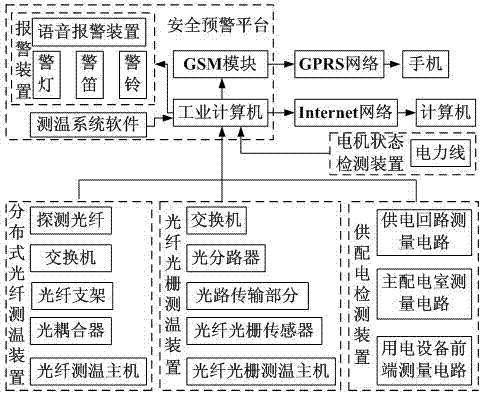

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0022] A mining equipment safety early warning system, its main technical features are: including a power supply and distribution detection device, a motor state detection device, a distributed optical fiber temperature measurement device, an optical fiber grating temperature measurement device and a safety early warning platform; wherein the safety early warning platform Including industrial computer, temperature measurement system software, GSM module and alarm device, the power supply and distribution detection device includes the main power distribution room measurement circuit, the front-end measurement circuit of the electrical equipment and the power supply circuit measurement circuit, and the motor state detection device includes the power line The distributed fiber optic temperature measurement device includes a detection fiber and a fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com