High-performance affinity chromatography for determining lactoferrin in dairy product

A technology of lactoferrin and high-performance liquid chromatography, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost of lactoferrin content, unsatisfactory separation, complicated pretreatment, etc., and achieve specificity High, low cost, simple pre-treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

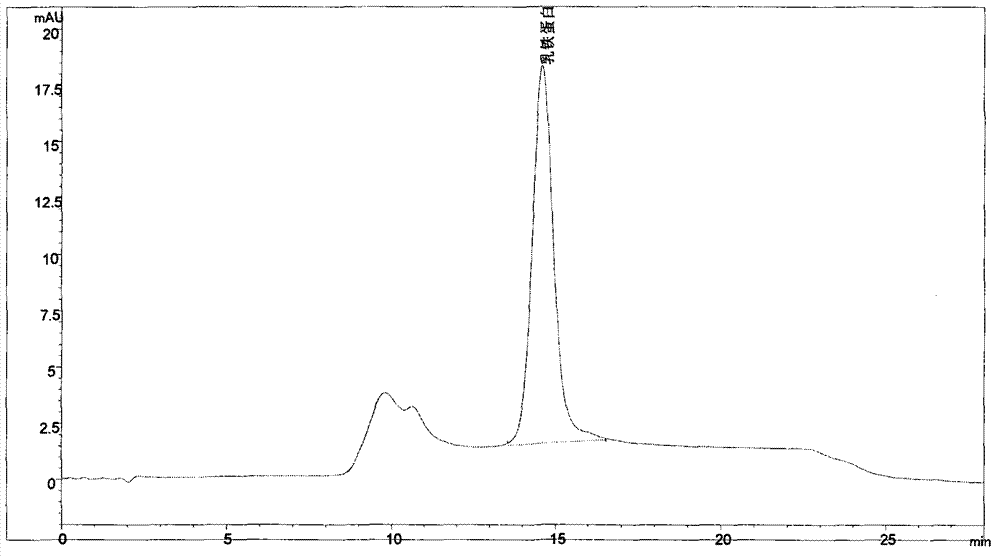

[0020] The mensuration of lactoferrin content in the formula milk powder of embodiment 1

[0021] 1. Sample extraction: Weigh 5.0g of the sample into a 50mL colorimetric tube, add 15mL of ultrapure water, vortex and mix, and then ultrasonically extract for 30min. After the extraction is completed, adjust the pH value to 4.6 with acetic acid, let stand for 10 minutes to precipitate casein, add ultrapure water to make the volume of the extract solution 25mL, vortex and mix, transfer 10mL extract solution to a 50mL centrifuge tube, and set the temperature at 8000r / min After centrifugation for 5 minutes, the supernatant was passed through a 0.45 μm water filter membrane, and the filtrate was tested.

[0022] 2. Determination by high performance liquid chromatography system: measure the sample and standard working solution according to the conditions of liquid chromatography, correct the concentration of the sample solution with the standard curve, and quantify with the external st...

Embodiment 2

[0034] The mensuration of lactoferrin content in embodiment 2 milk and human milk

[0035] 1. Sample extraction: with embodiment 1.

[0036] 2. Determination conditions of high performance liquid chromatography system: same as example 1.

[0037] 3. Linear relationship: with embodiment 1.

[0038] 4. Actual sample measurement, precision and accuracy:

[0039] The lactoferrin content in a certain milk sample was measured in parallel for 6 times, and the precision was calculated. The content of lactoferrin in this milk sample was 14.06mg / 100g, and the relative standard deviation was 1.5%.

[0040] Two human milk samples were measured in parallel, and the calculated result was that the content of lactoferrin in A human milk was 351.4mg / 100g, and the content of lactoferrin in B human milk was 100.6mg / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com