Compound soft die for wafer-grade nano imprinting of uneven substrate and manufacturing method

A substrate wafer, nano-imprinting technology, applied in the process of producing decorative surface effects, manufacturing microstructure devices, photoplate process of patterned surface, etc. Wafer-level nanoimprint process requirements and other issues to achieve good large-area conformal contact, high resistance to deformation, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

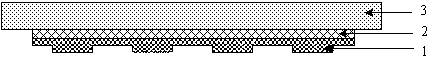

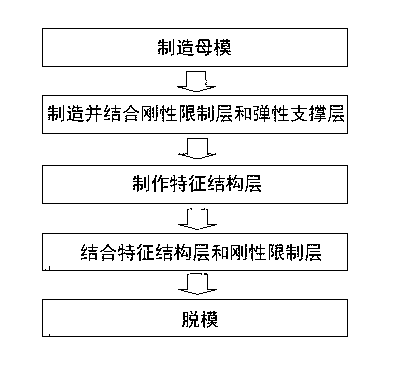

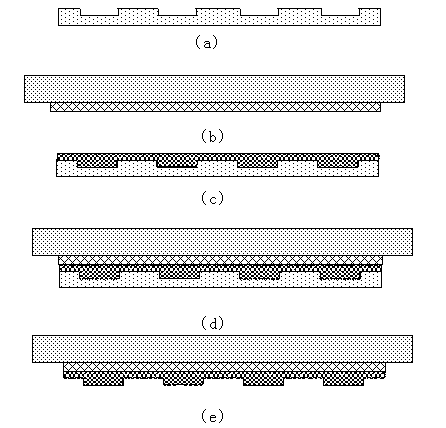

[0039] figure 1 Among them, the composite soft mold for non-flat substrate wafer-level nanoimprinting in this embodiment includes: a characteristic structure layer 1, a rigid confinement layer 2, and an elastic support layer 3; wherein, the characteristic structure layer 1 has a low surface energy, The characteristics of high elastic modulus, high hardness and transparency; the rigid limiting layer 2 has the characteristics of transparency and high elastic modulus; the elastic support layer 3 has the characteristics of transparency and high elasticity. The characteristic structure layer 1 includes the micro-nano pattern structure to be replicated; the rigid confinement layer 2 is located on the characteristic structure layer 1, limiting the lateral deformation and longitudinal deformation of the characteristic structure layer 1; the elastic support laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com