Surface-conduction electron emission source based on graphene

A technology for conducting electrons and secondary electron emission, applied in circuits, electrical components, parts of discharge tubes/lamps, etc., can solve the problems of increasing the complexity of driving circuits, low electron emission efficiency, low emission efficiency, etc. The effect of improved emission efficiency, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

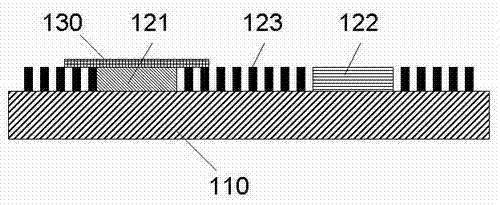

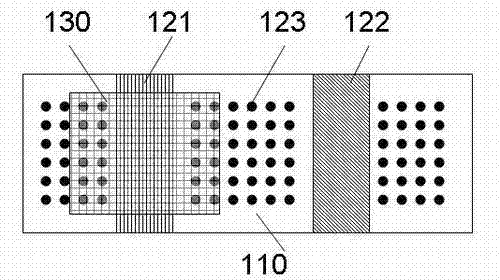

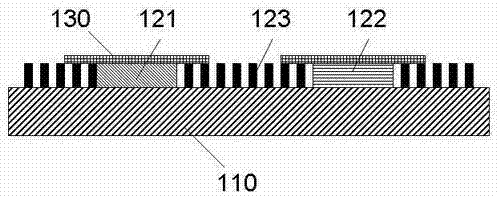

[0032] Step 1, refer to Figure 8 , forming electrodes 121 and 122 on the surface of the substrate 110, the first embodiment of the present invention preferably adopts photosensitive silver paste electrodes, and the specific process includes:

[0033] (a) Spin coating of photosensitive silver paste. The photosensitive silver was transferred to the surface of the substrate 110 by using a spin-coating process, and kept at 110° C. for 20 minutes. The used substrate can be selected from glass, quartz, pottery, and high-temperature-resistant materials with an insulating layer on the surface.

[0034] (b) Exposure. The pre-dried photosensitive silver paste film layer is naturally cooled to room temperature before exposure, and the mask plate of the cathode pattern is covered on the photosensitive silver paste film layer. The photosensitizer of the photosensitive silver paste is negative, so the pattern subjected to ultraviolet light is exposed Light curing, graphics that are not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com