Pressure container curing chamber and curing method thereof

A pressure vessel and curing chamber technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problem of not shortening the process time, and achieve the effect of shortening the oxidation time, increasing the oxygen concentration, and shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

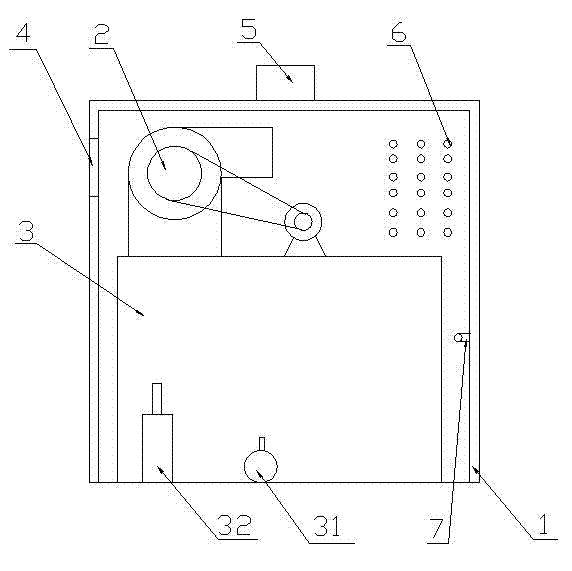

[0016] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0017] A pressure vessel curing chamber, comprising a curing chamber 1, a circulation fan 2 and a pressure vessel chamber 3 are respectively arranged inside the curing chamber 1, a steam generator 31 and an atomizer 32 are arranged in the pressure vessel chamber 3, and the outside of the curing chamber 1 is arranged A PLC control device, a compressed air inlet 4 and a vacuum compressor interface 5 are respectively arranged on the side wall of the curing chamber 1 , and a compressed air heater 6 is arranged between the pressure vessel chamber 3 and the curing chamber 1 .

[0018] The outer surface of the curing chamber 1 of the present invention is attached with a polyurethane insulation layer. A stainless steel layer is attached to the inner surface of the curing chamber 1 . The inner surface of the curing chamber 1 is provided with a temperature and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com