Red-type light emitting phosphor, method for producing same and light emitting device using red-type light emitting phosphor

A technology of light-emitting devices and phosphors, applied in the direction of light-emitting materials, chemical instruments and methods, semiconductor devices, etc., can solve problems such as no specific description, and achieve the effect of improving life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (Example 1, Comparative Example 1)

[0082] Example 1: Activation of a nitride red light-emitting phosphor (Ca 0.99 Eu 0.01 )AlSiN 3 10g, add pure water 100g, 96% concentrated sulfuric acid (H 2 SO 4 ) 1 g and 46% hydrofluoric acid (HF) 1 g, the temperature was adjusted to 50° C., and stirred for 20 minutes. Thereafter, the red light-emitting phosphor was allowed to settle, and the supernatant was removed. This operation was repeated 3 times. Then, 100 g of pure water was added to the red light-emitting phosphor, the temperature was adjusted to 80° C., and the mixture was stirred for 20 minutes. Thereafter, the red light-emitting phosphor was allowed to settle, and the supernatant was removed. This operation was repeated 10 times. Finally, the red light-emitting phosphor was allowed to settle, and the conductivity of the supernatant was measured at room temperature, and it was 10 μs / cm.

[0083] The divalent europium-activated nitride red light-emitting phospho...

Embodiment 2~6、 comparative example 2~6

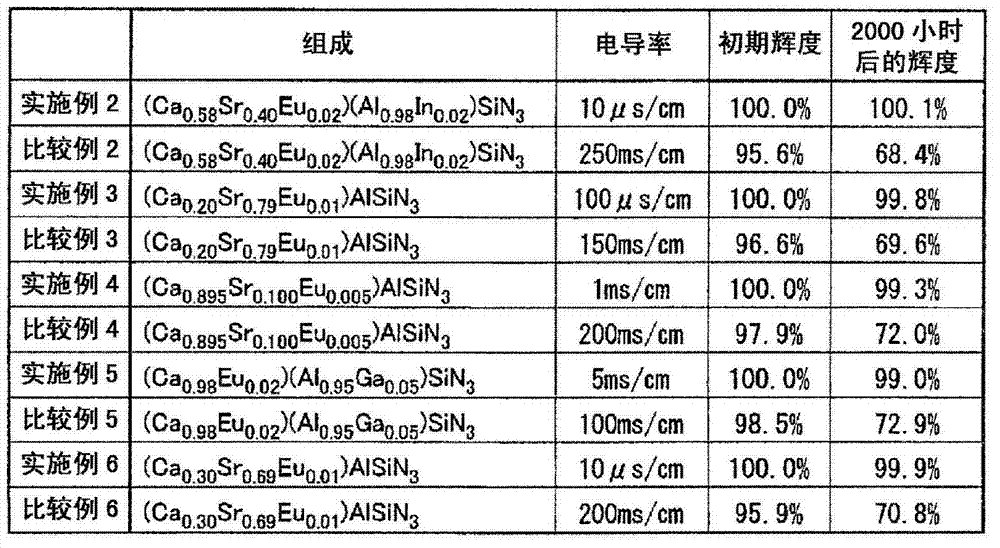

[0091] For the divalent europium-activated nitride red light-emitting phosphor, samples having various compositions and electrical conductivity were evaluated in the same manner as in Example 1, and the results are shown in Table 2.

[0092] [Table 2]

[0093]

[0094] As can be clearly seen from Table 2, compared with Comparative Examples 2 to 6, the red-based light-emitting phosphors of Examples 2 to 6 have excellent initial luminance, and the luminance after 2000 hours is also good, and the life characteristics are greatly improved. improve.

[0095]

Embodiment 7

[0096] (Example 7, Comparative Example 7)

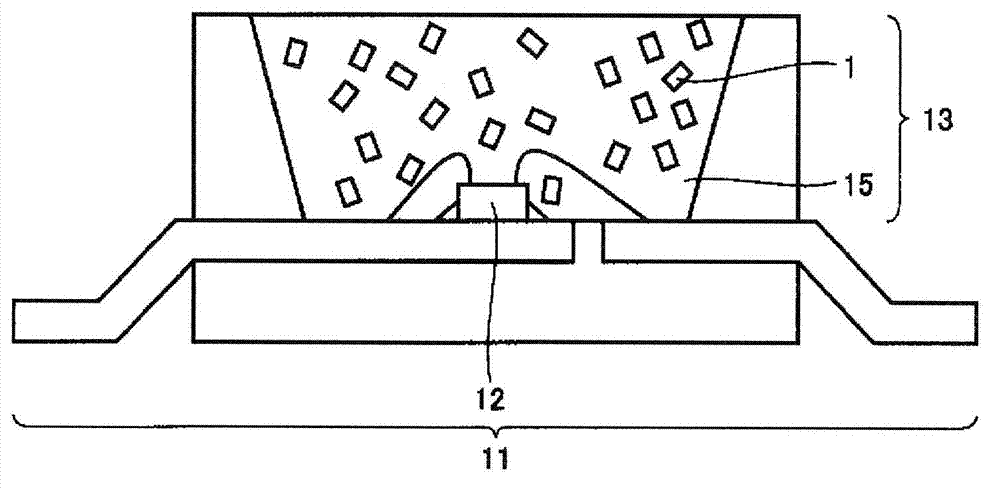

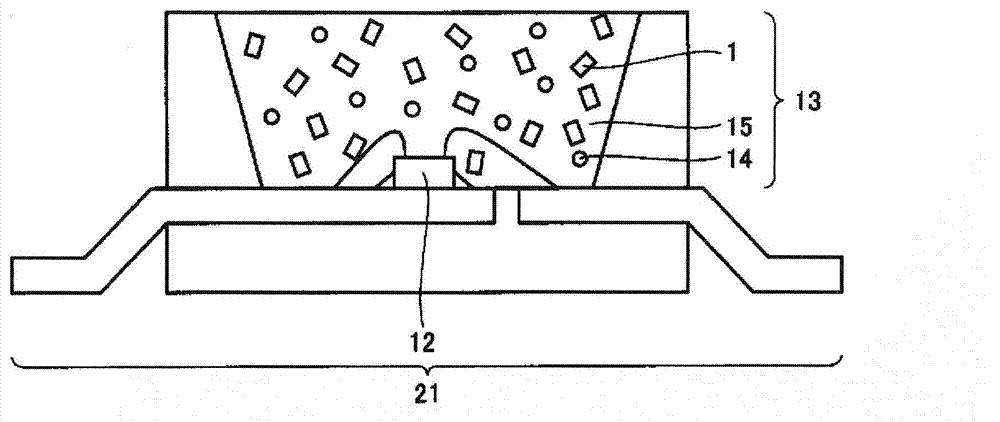

[0097] Example 7: A gallium nitride (GaN)-based semiconductor having a peak wavelength at 450 nm was used as a light-emitting element. In the wavelength conversion part, a divalent europium-activated nitride phosphor having an electrical conductivity of 20 μs / cm of the supernatant of a solution containing 10 parts by mass of pure water to 1 part by mass of the phosphor was used as a red light emitting phosphor (Ca 0.99 Eu 0.01 )AlSiN 3 , as a green-based light-emitting phosphor, Eu 0.05 Si 11.55 Al 0.45 o 0.35 N 15.65 A green-based light-emitting phosphor with a composition of (β-type SIALON). These red-based light-emitting phosphors and green-based light-emitting phosphors were mixed at a mass ratio of 1:2.7, and the obtained materials were dispersed in a heat-curable silicone resin sealing material as a medium, and the light-emitting element was sealed. The wavelength conversion part was produced, and the light-emitting de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com