Insecticide for killing termites and preparation method of insecticide

A technology of medicaments and termites, applied in botany equipment and methods, insecticides, biocides, etc., can solve the long-term problem. It takes more than 3 months to kill a termite population, and some even take nearly a year. The control effect is not ideal, and the ant colony cannot be effectively killed, etc., to achieve the effect of good control effect, simple preparation and use, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

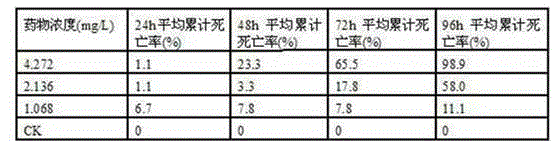

[0018] Example 1: Measuring the Toxicity of Chlorfenapyr to Termites

[0019] test methods:

[0020] The 98.1% chlorfenapyr original drug was prepared into a series of concentrations with acetone. Use a pipette to pipette 1ml of the drug solution and evenly drop it on the filter paper (Φ9cm) to form a drug film, dry it naturally and put it into a clean Petri dish (Φ9cm). Add 1ml of double-distilled water dropwise, and put in 30 milk termite worker ants for continuous contact. 3 repetitions, set a blank control, record and observe the number of dead termites every day, and calculate the LC 50 Value, the test is carried out at 28±1°C, under dark conditions, and keep the filter paper moist.

[0021] Implementation Effect:

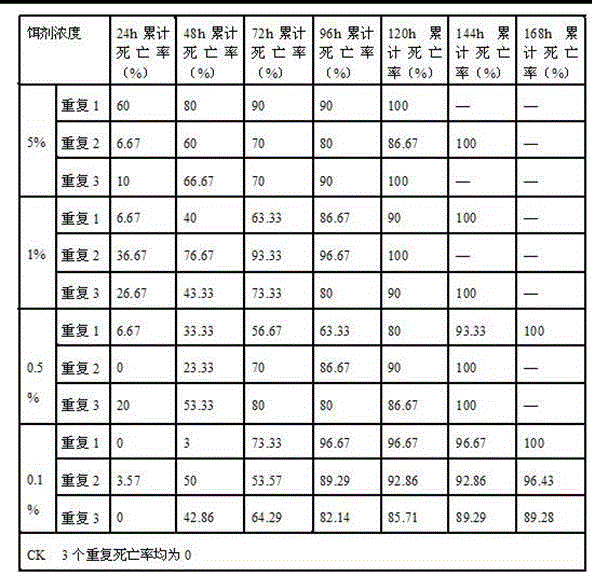

[0022] Table 1 Toxicity determination of chlorfenapyr original drug film method to milk termites

[0023]

[0024] It can be seen from Table 1 that after the drug treatment, the termite mortality rate was very low within 24h and 48h, and the...

Embodiment 2

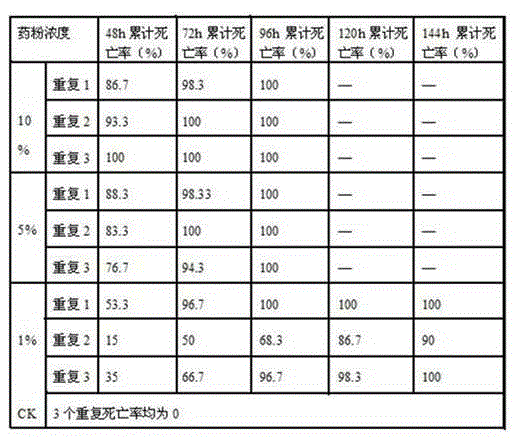

[0025] Embodiment 2: the preparation of powder, used in embodiment 4.

[0026] Weigh 4000 mg of talcum powder, 80 mg of vanillin, and 454 mg of 98.1% chlorfenapyr powder, mix them together, and stir evenly to prepare 10% chlorfenapyr powder.

[0027] Weigh 4000 mg of talcum powder, 80 mg of vanillin, and 215 mg of 98.1% chlorfenapyr powder, mix them together, and stir evenly to prepare 5% chlorfenapyr powder.

[0028] Weigh 4000 mg of talcum powder, 90 mg of vanillin, and 41 mg of 98.1% chlorfenapyr powder, mix them together, and stir evenly to prepare 1% chlorfenapyr powder.

Embodiment 3

[0029] Embodiment 3: the preparation of bait, used in embodiment 5.

[0030] Pass the pine sawdust through a 1 mm sieve, place it in a constant temperature drying oven, keep it at (60±1)°C for 24 hours, and take it out for later use. Use an analytical balance to weigh 4000 mg of pine sawdust, 100 mg of vanillin, 400 mg of soft white sugar, and 290 mg of 98.1% chlorfenapyr powder, pour them into a beaker and mix well. Weigh 1000 mg of agar powder, add 30 mL of distilled water, stir and heat in a microwave until boiling, add 10 mg of sorbic acid, and stir evenly. Pour into the mixture in the beaker while hot and stir well. That is, 5% chlorfenapyr bait was prepared. Let cool and serve.

[0031] The preparation of 1% chlorfenapyr bait was the same as above, except that 56 mg of 98.1% chlorfenapyr powder was weighed.

[0032] The preparation of 0.5% chlorfenapyr bait was the same as above, except that 28 mg of 98.1% chlorfenapyr powder was weighed.

[0033] The preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com