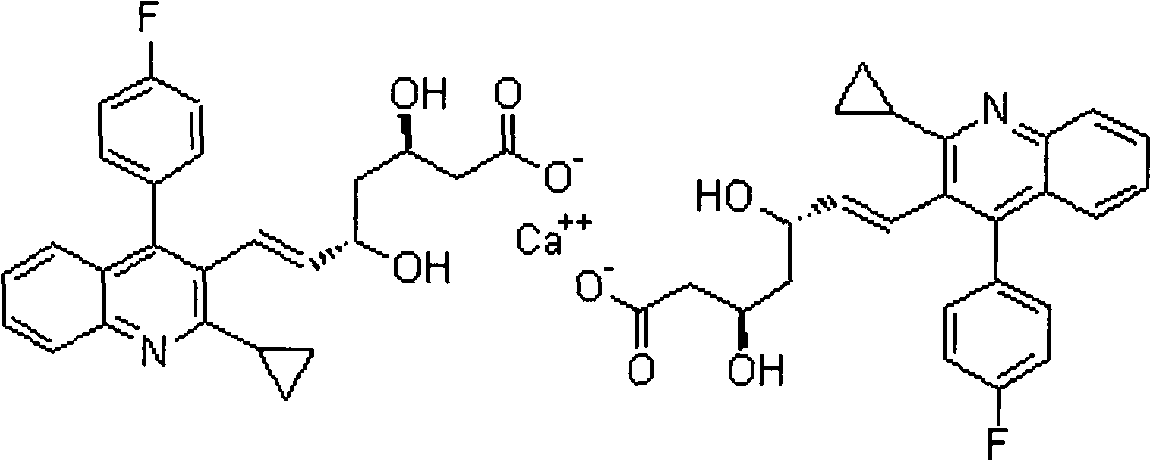

Pitavastatin calcium preparation and preparation technology

A technology of pitavastatin calcium and preparations, which is applied in the direction of pill delivery, medical preparations of non-active ingredients, sugar-coated pills, etc., and can solve problems such as poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

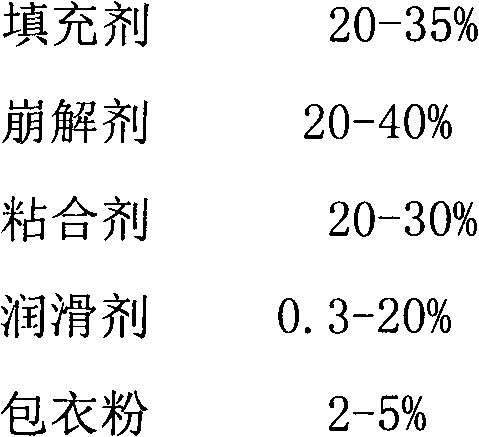

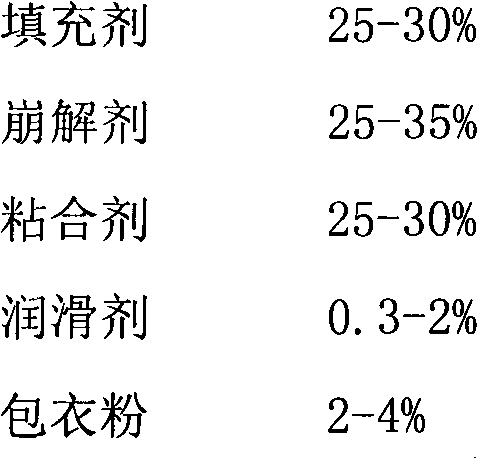

[0036]

[0037] Powder direct compression process:

[0038] Mixing and granulation: first mix the main drug and excipients with good fluidity uniformly according to the method of equal volume addition, and then mix them with other excipients in a high-efficiency mixer, take samples, measure the content of intermediates, and determine the tablet weight;

[0039] Tablet compression: that is, it is compressed into tablets of suitable size on a tablet press;

[0040] Coating: Opadry is made into an aqueous dispersion of film-coating liquid, and the plain tablets are film-coated by a high-efficiency coating machine to obtain pitavastatin calcium film-coated tablets, with a weight gain of about 3%.

[0041] Wet granulation process:

[0042] Mixing and granulation: first mix the main drug and excipients with good fluidity by the method of equal volume addition, then mix them with other excipients in a high-efficiency mixer, and add povidone K 30 The aqueous solution is used as a...

Embodiment 2

[0049]

[0050] Powder direct compression process:

[0051] Mixing and granulation: first mix the main drug and excipients with good fluidity uniformly according to the method of equal volume addition, and then mix them with other excipients in a high-efficiency mixer, take samples, measure the content of intermediates, and determine the tablet weight;

[0052] Tablet compression: that is, it is compressed into tablets of suitable size on a tablet press;

[0053] Coating: Opadry is made into an aqueous dispersion of film-coating liquid, and the plain tablets are film-coated by a high-efficiency coating machine to obtain pitavastatin calcium film-coated tablets, with a weight gain of about 3%.

[0054] The film-coated tablet was accelerated for three months at 40°C and 75%, and its content was 98.0%. Related substances: isomers 0.22%, lactone 0.21%, other simple impurities 0.06%, total impurities 0.8%, all qualified .

Embodiment 3

[0056]

[0057] Powder direct compression process:

[0058] Mixing and granulation: first mix the main drug and excipients with good fluidity uniformly according to the method of equal volume addition, and then mix them with other excipients in a high-efficiency mixer, take samples, measure the content of intermediates, and determine the tablet weight;

[0059] Tablet compression: that is, it is compressed into tablets of suitable size on a tablet press;

[0060] Coating: Opadry is made into a film-coating aqueous dispersion, and the plain tablets are film-coated by a high-efficiency coating machine to obtain pitavastatin calcium film-coated tablets, with a weight gain of about 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com