Device for treating organic waste gas by applying photochemical technology

A technology for organic waste gas and technical treatment, applied in chemical instruments and methods, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of large area, difficult to apply large organic waste gas, complex operation and management, etc., to achieve regeneration, achieve sustainable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

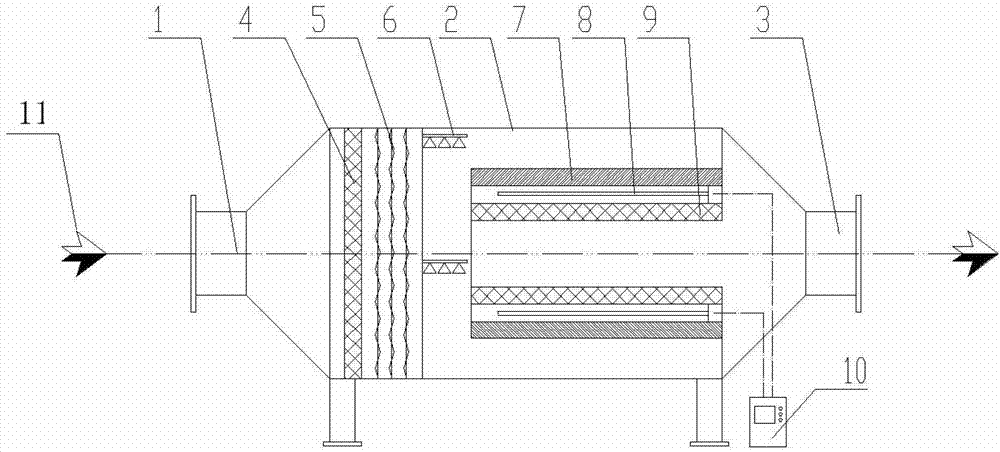

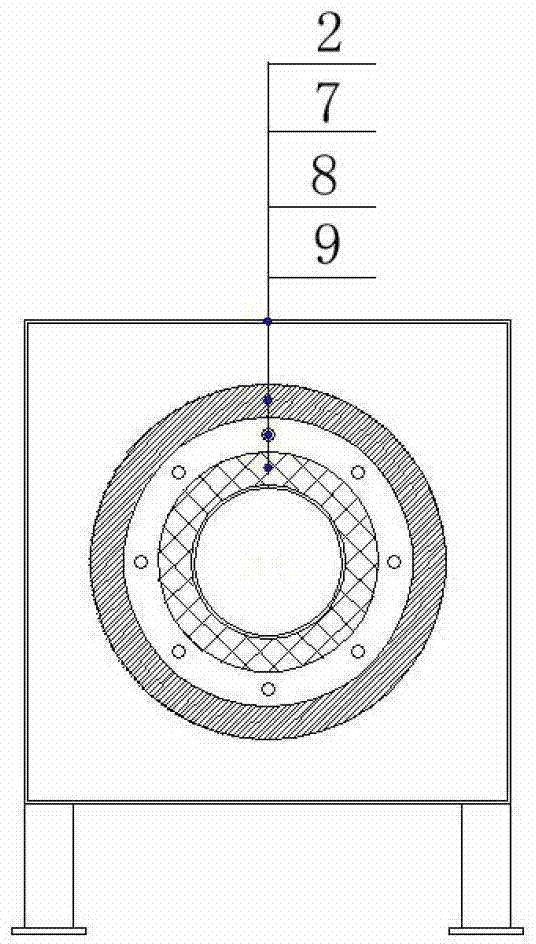

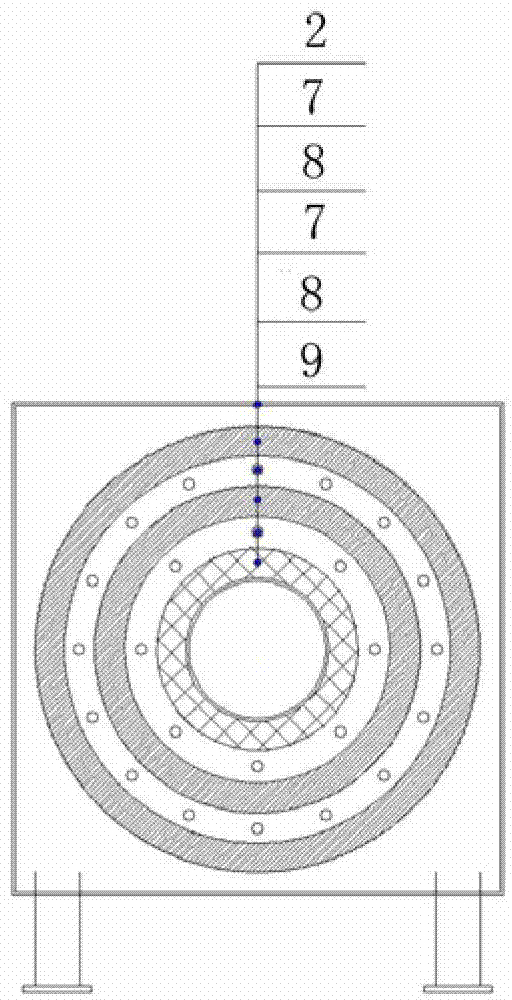

[0032]Such as Figure 1 to Figure 4 As shown, this embodiment is a device for treating organic waste gas using photochemical technology, including air inlet flange 1, equipment steel structure main body 2, air outlet flange 3, high-strength security filter 4, plasma reactor 5, liquid mist Humidifier 6, cylindrical catalytic reaction network 7, ultraviolet lamp group 8, cylindrical adsorption reaction network 9 and electrical controller 10; At the end, the high-strength security filter 4, the plasma reactor 5, the liquid mist humidifier 6, the cylindrical catalytic reaction net 7, the ultraviolet lamp group 8 and the cylindrical adsorption reaction net 9 are all arranged in the steel structure main body 2 of the equipment, among which , the high-strength security filter 4 is made of stainless steel and composite material fibers, and is arranged behind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com