Stirring type reacting kettle

A reaction kettle and stirring technology, applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of low movement speed, lower production efficiency and production quality, and inability to react efficiently with gas, so as to promote absorption, The effect of improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

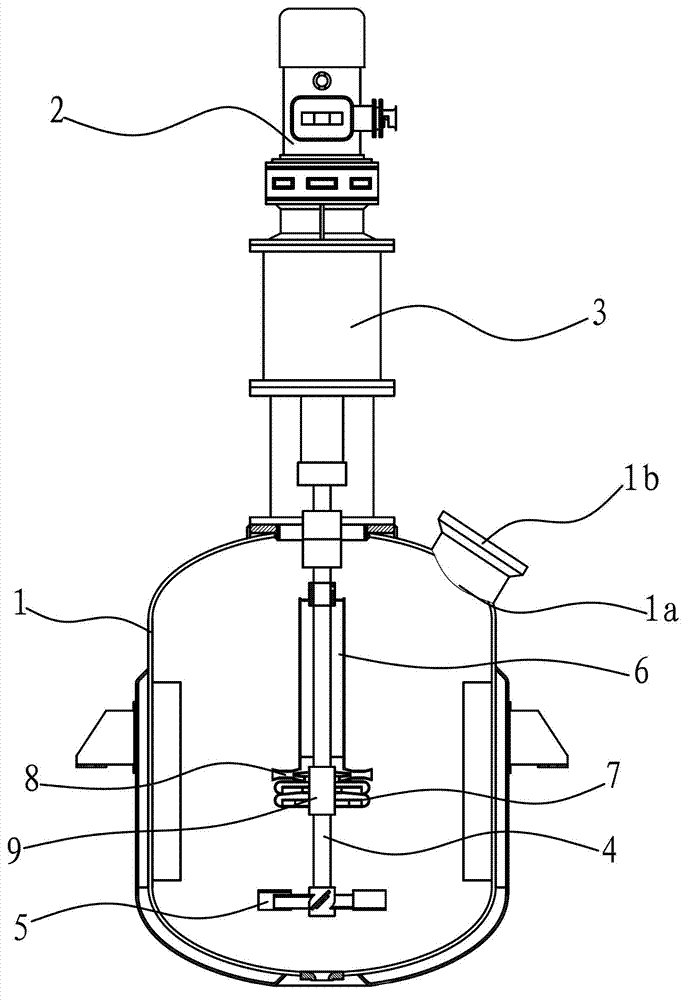

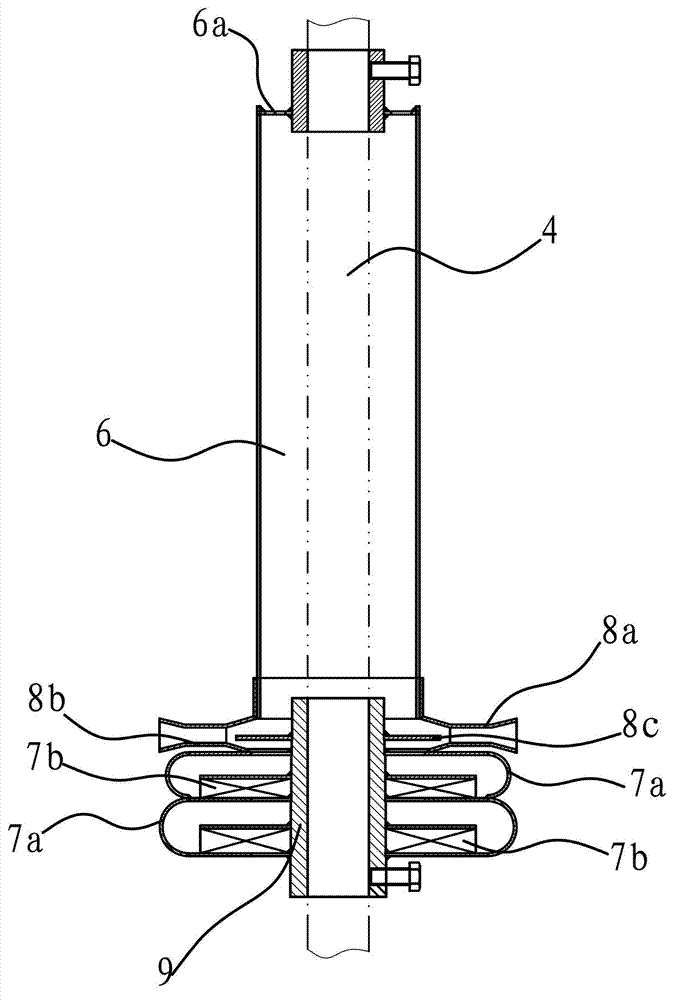

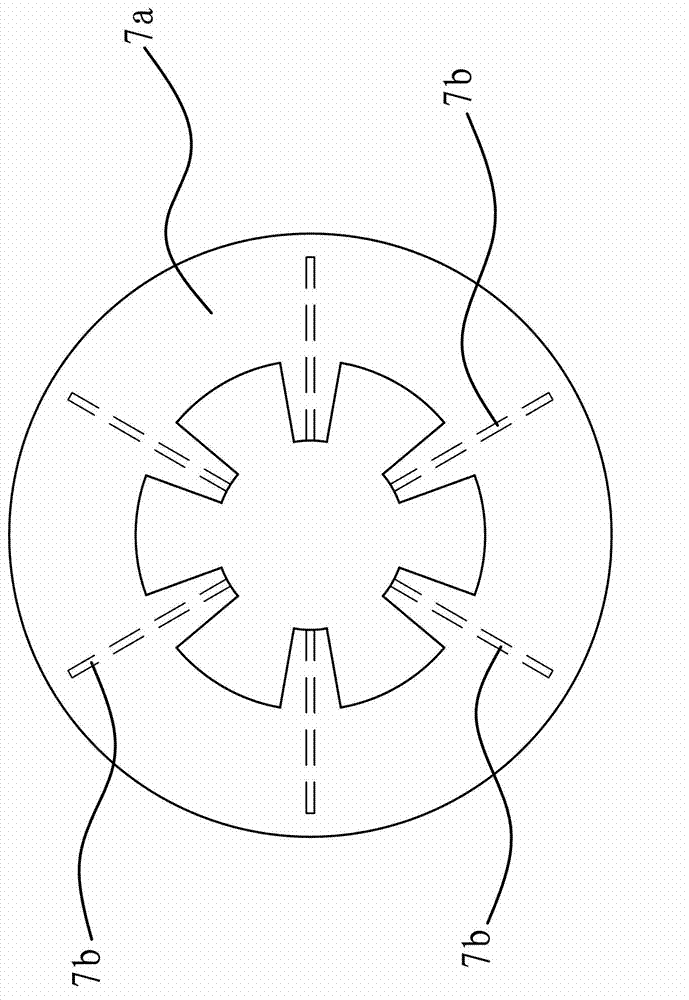

[0023] Such as figure 1 , figure 2 , image 3 As shown, the stirred reactor includes a closed cylinder 1, the upper part of the cylinder 1 is inserted into the stirring rod 4, the upper end of the stirring rod 4 is provided with a motor 2, the bottom end of the stirring rod 4 is fixedly connected with the stirring paddle 5, and the middle part of the stirring rod 4 is socketed. There are gas guide sleeves 6 and several stirring components 7 for accelerating the flow rate of the reaction liquid, and a gas-liquid mixing component 8 is arranged between them.

[0024] The cylinder body 1 has a sealed reaction chamber, and the upper part of the cylinder body 1 also has a feed port 1a for feeding raw materials, and the feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com