Production device and production method of calcium citrate

A production device and technology of calcium citrate, applied in chemical instruments and methods, carboxylate preparation, organic chemistry, etc., can solve problems such as difficulty in solid-liquid separation, large amount of calcium carbonate entrapment, and incomplete reaction of calcium carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

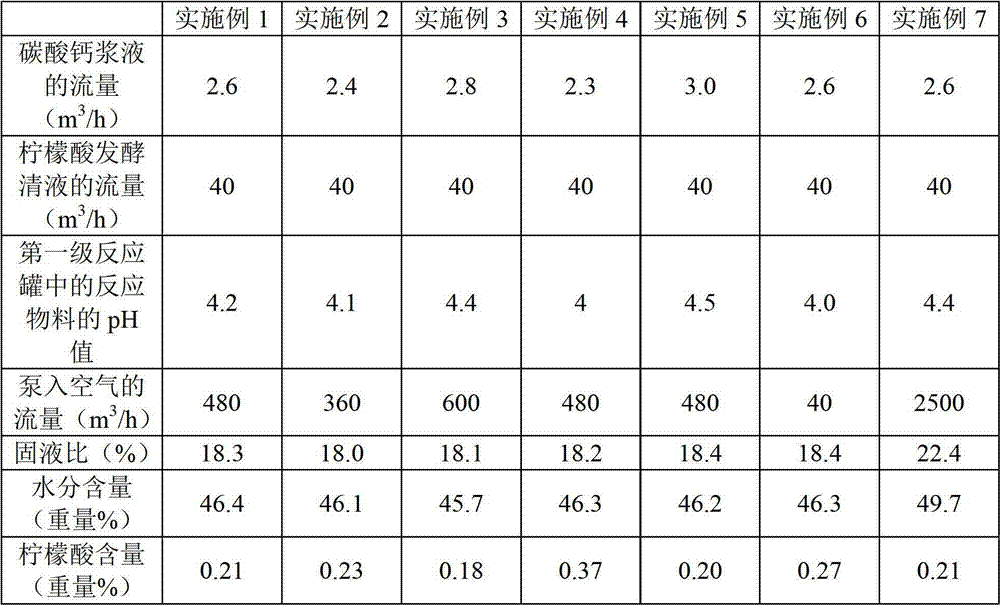

Embodiment 1-7

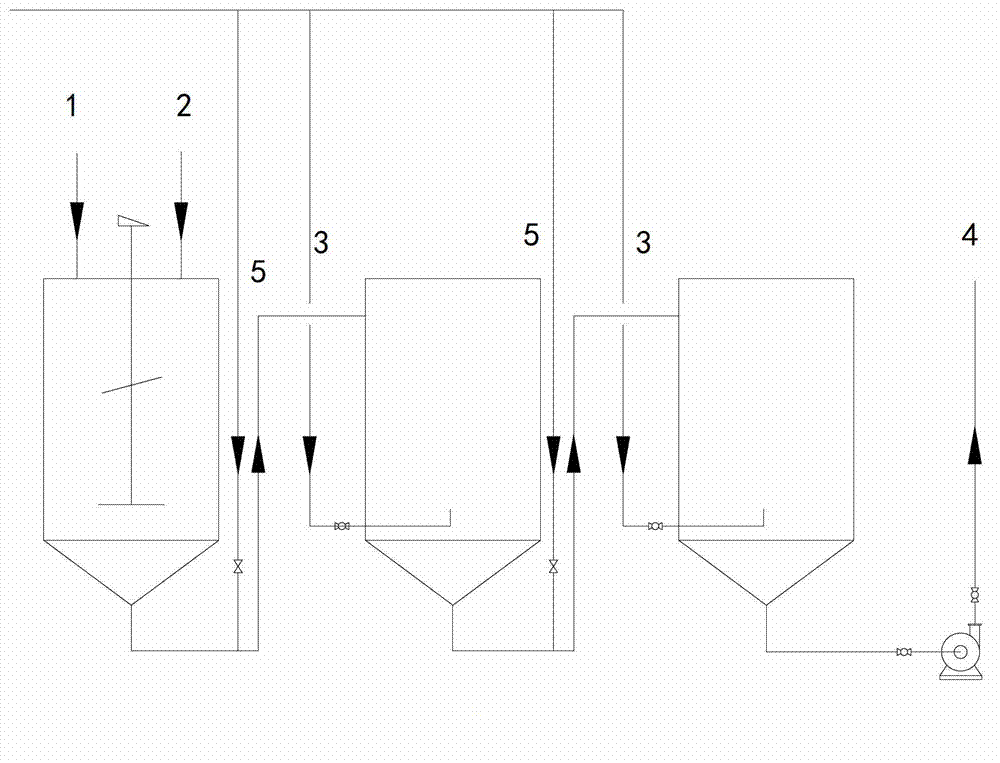

[0054] In these embodiments, the production equipment that uses comprises the three-stage reaction tank that connects in series successively (the effective volume of each reaction tank is 12m 3 , and the height is 4m), the reaction tanks at all levels include feed inlets and discharge ports respectively, the heights of the reaction tanks at all levels are the same, and the discharge ports of the reaction tanks at all levels are located at the bottom of the reaction tanks, except for the first stage The vertical distance between the feed ports of the reaction tanks at all levels outside the reaction tank and the top of the reaction tank is 20% of the height of the reaction tank. The discharge port of the reaction tank is connected through a communication pipe. The first-stage reaction tank located at the first place is provided with a stirring device, and the communication pipe of the adjacent two-stage reaction tank is also provided with a device capable of pumping into the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com