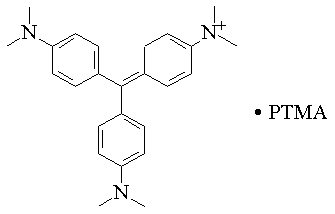

Preparation method of pigment purple 3

A pigment violet and pigment technology, applied in the field of preparation of C.I. Pigment Violet 3, can solve the problems of environmental water pollution, high COD value, incomplete laking of basic violet dyes, etc., and achieve minimal environmental pollution and good weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of C.I. Pigment Violet 3 comprises the steps:

[0026] (1) Preparation of heteropolyacid:

[0027] Add 9.5 grams of sodium tungstate, 0.95 grams of sodium molybdate, and 1.43 grams of disodium hydrogen phosphate into hot water at 85°C, stir well to dissolve them completely, then add 38 grams of hydrochloric acid with a concentration of 30%, and react for 1 hour until pH To about 1.5, after the pH value is stable, prepare the heteropolyacid standby solution;

[0028] (2) Dissolution of dye

[0029] Dissolve 0.5g of glacial acetic acid in 1500g of water, heat up to 80°C, add 10g of basic violet, then add a transparent mixture of 0.2g of fatty alcohol polyoxyethylene ether and 10g of 50°C water (surfactant solution) , fully stirred to dissolve completely, reacted for 0.5h, and then lowered the temperature to 50°C to prepare the dye stock solution;

[0030] (3) Pigment laking

[0031] Filter the heteropolyacid prepared in step (1) a...

Embodiment 2

[0035] The preparation method of C.I. Pigment Violet 3 comprises the steps:

[0036] (1) Preparation of heteropolyacid:

[0037] Add 10 grams of sodium tungstate, 3 grams of sodium molybdate, and 2 grams of disodium hydrogen phosphate into hot water at 65°C, stir well to dissolve them completely, then add 4 grams of sulfuric acid with a concentration of 98%, 30 grams of sulfuric acid with a concentration of 30 % hydrochloric acid, react for 1h, until the pH reaches about 2.5, and after the pH value is stable, prepare the heteropolyacid standby solution;

[0038] (2) Dissolution of dye

[0039] Dissolve 1 gram of glacial acetic acid in 1500 grams of water, heat up to 95°C, add 10 grams of basic violet, and then add a transparent mixture of 0.2 grams of alkylphenol polyoxyethylene ether and 10 grams of water at 60°C (surfactant solution ), fully stirred to dissolve completely, reacted for 0.5h, and then lowered the temperature to 60°C to prepare the dye stock solut...

Embodiment 3

[0045] The preparation method of C.I. Pigment Violet 3 comprises the steps:

[0046] (1) Preparation of heteropolyacid:

[0047] Add 10.5 grams of sodium tungstate, 5.25 grams of sodium molybdate, and 4.2 grams of disodium hydrogen phosphate into hot water at 90°C, stir well to dissolve them completely, then add 52.5 grams of 30% hydrochloric acid, and react for 1 hour until pH To about 3.5, after the pH value is stable, prepare the heteropolyacid standby solution;

[0048] (2) Dissolution of dye

[0049] Dissolve 2 grams of glacial acetic acid in 1500 grams of water, heat up to 100°C, add 10 grams of basic violet, and then add a transparent mixture of 0.2 grams of sodium alkylsulfonate and 10 grams of 60°C water (surfactant solution), Thoroughly stir to dissolve completely, react for 0.5h, then lower the temperature to 70°C to prepare the dye stock solution;

[0050] (3) Pigment laking

[0051] Filter the heteropolyacid obtained in step (1) and add it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com