Method for wall breaking for beer yeast

A brewer's yeast and beer-flavor technology, applied in the biological field, can solve the problems of long wall breaking time, strong yeast taste, insufficient umami, etc., and achieve the effect of solving the problem of strong taste, fresh taste and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

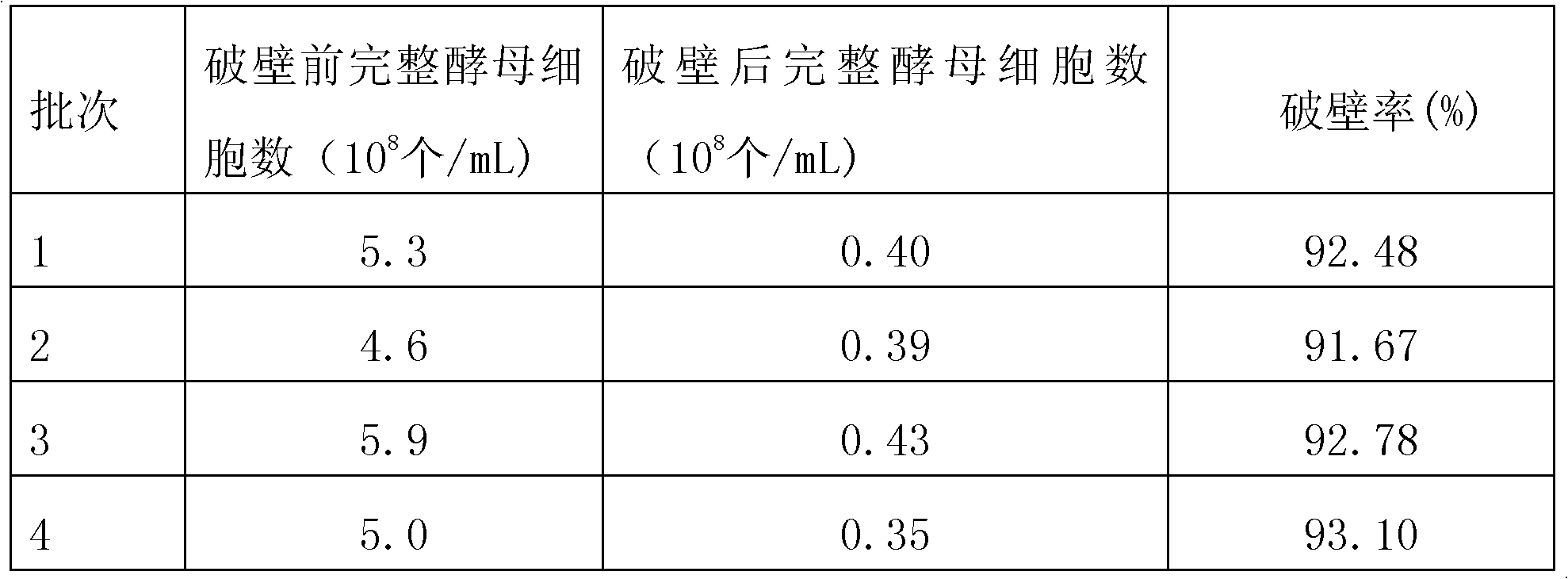

Image

Examples

Embodiment 1

[0037] processing flow

[0038] A method for breaking the wall of brewer's yeast, comprising the following steps:

[0039] (1) Through the flow process of adding water, stirring, and centrifugal dehydration, the brewer's yeast leftovers are washed until there is no beer taste, and then passed through a 70-mesh sieve to obtain washed and sieved brewer's yeast sludge;

[0040] The function of this step: remove miscellaneous smell and particle impurities;

[0041] (2) Add washed and sieved beer yeast mud and clean water into the hydrolysis tank, the weight ratio of beer yeast mud and water is 1:4, start the mixer, and stir at 100 rpm / Min for 0.5 hours;

[0042] (3) Start the heating device, uniformly heat the contents in the hydrolysis tank to 90° C. within 0.3 hours to 0.5 hours, and then maintain the temperature of the contents in the hydrolysis tank at 90° C. for 0.5 hours;

[0043] The effect of this step: to sterilize the hydrolysis tank and its contents;

[0044] (4) Nat...

Embodiment 2

[0061] In order to make better use of the contents of yeast cells released by breaking the wall, a simple and effective method for processing the contents of yeast cells is provided here, including the following steps:

[0062] (S1) Control the temperature of the yeast solution (such as the solution obtained in the above step (7)) to 37° C., and adjust the pH value to 4.5-6;

[0063] (S2) Bacteria species: add bacterial liquid to the yeast solution, the ratio of the volume of the bacterial liquid to the volume of the yeast solution is 0.1%-1%. Bacterial composition, the amount of live bacteria in the bacterial liquid is 2×10 10 CFU / L;

[0064] (S3) Fermentation: keep at 37° C. for 32-40 hours.

[0065] The above processing method uses the contents of the yeast cells released by breaking the wall as the medium, and uses specific probiotics for fermentation and expansion culture, which can increase the biological activity of the output, and can impart a fresh fragrance and eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com