Intermittent on-off type mass concrete cooling water supply control system

A large-volume concrete and control system technology, which is applied in the direction of temperature control, construction, and building construction using electric methods, can solve the problems of flow sensors not working properly, increased manpower and equipment investment, and slow information feedback, etc., to reduce Difficulty in maintenance, lower control cost, and less manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

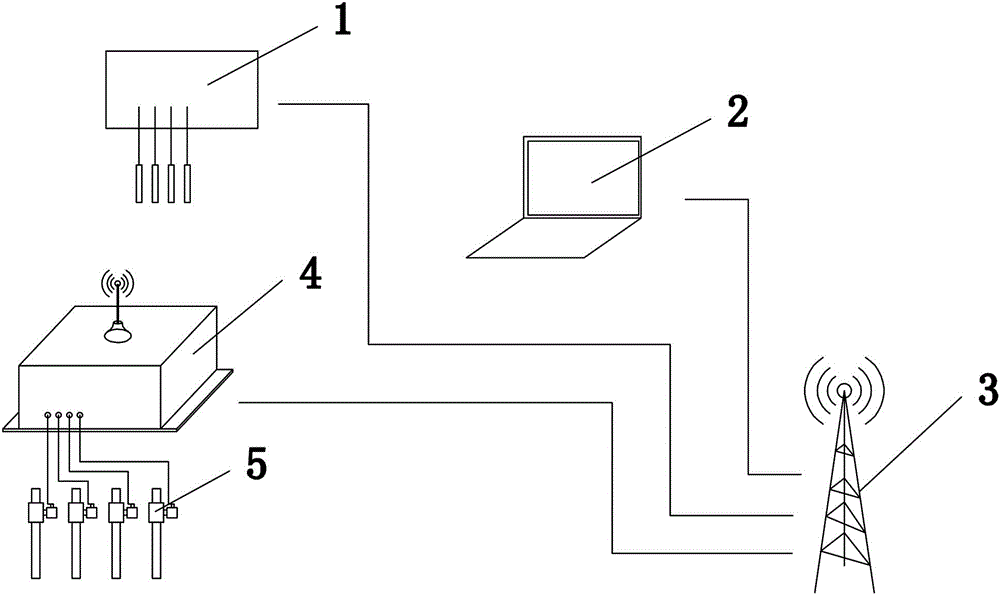

[0036] Such as figure 1 Among them, an intermittent on-off large-volume concrete cooling water control device, including:

[0037] Concrete temperature acquisition system 1, that is, to measure the concrete temperature with a temperature sensor; in this example, the optimal solution is to use a wireless telemetry temperature sensor, but in some projects, a wired temperature sensor will also be configured, which is usually carried out simultaneously with the pouring construction. It is also feasible to configure the temperature sensor in a wired manner.

[0038] The control terminal 2 is used to obtain the temperature signal of the concrete temperature acquisition system 1 and compare it with the set control target temperature, and then send a control signal; the control signal is usually a signal to control the on-off of a certain electric valve 5, that is, the above-mentioned The control signal is an on-off control signal. When the concrete temperature is higher than the co...

Embodiment 2

[0043] A kind of method adopting the device of embodiment 1 to carry out cooling water flow control, comprises the following steps:

[0044] 1. Arrange the concrete temperature acquisition system 1 to obtain the concrete temperature through the temperature sensor; the temperature sensor and the electric valve 5 are grouped according to the cooling water pipe, that is, the temperature sensor used to measure the temperature of the concrete near the cooling water pipe is connected with the temperature sensor on the cooling water pipe. The electric valve 5 is a group. The temperature data acquired by the temperature sensors in this group are also only used to control the electric valves 5 of this group.

[0045] 2. Install the control terminal 2, which is used to obtain the temperature signal of the concrete temperature acquisition system 1, and compare it with the set control target temperature, and then send a control signal. When the concrete temperature is higher than the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com