Manufacturing method of low-fat high-stability soybean ice cream

A technology with high stability and production method, applied in frozen desserts, protein food processing, vegetable protein processing and other directions, can solve the problems of poor stability, low viscosity and easy collapse of low-fat ice cream, and achieve suitable taste, improved quality and aroma. pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] (1) Preparation of high-stability soybean protein: using soybean protein isolate as raw material, using papain to enzymolyze the degree of hydrolysis to 6%; High stability soybean protein obtained by spray drying;

[0041] (2) Raw material pretreatment: Stir high-stability soybean protein, skimmed milk powder, stabilizer, and sugar evenly and completely dissolve them in water at 55-60°C, add dissolved anhydrous butter and emulsifier, and keep stirring;

[0042] (3) Pasteurization: Sterilize with a sterilizer at a temperature of 80-85°C for 15-10 minutes;

[0043] (4) Homogenization: cooling to 65-70°C for homogenization, the first-stage homogenization pressure is 16MPa, and the second-stage homogenization pressure is 4Mpa;

[0044] (5) Aging: Aging at 4°C, the aging time is 4h;

[0045] (6) Freezing: at -15~-20°C, the freezing time is 20 minutes;

[0046] (7) Hardening: at -18°C, the hardening time is 24h.

[0047] The papain enzymatic hydrolysis conditions are as f...

Embodiment 1

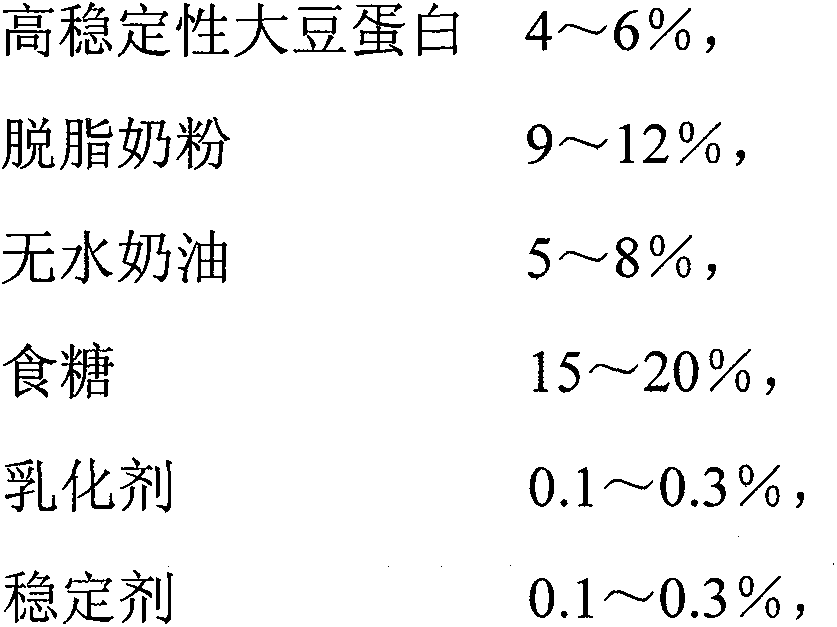

[0051] A kind of preparation method of low-fat high-stability soybean ice cream, raw material consumption is as follows (100g): high emulsification stability soybean protein 4g; Skim milk powder 8g; Anhydrous cream 8g; Sucrose 15g; Glyceride 0.2g; water 64.6g.

[0052] (1) Preparation of high-stability soybean protein: use soybean protein isolate as raw material, use papain (enzyme activity 800,000 U / g, substrate concentration 5%, enzyme / substrate = 3%) to hydrolyze for 30 minutes to achieve hydrolysis The hydrolyzed sample was added with transglutaminase (enzyme activity 100U / g, enzyme / substrate = 2.5%) to cross-link for 1 hour after deactivating the enzyme, and obtained by spray drying after deactivating the enzyme.

[0053] (2) Raw material pretreatment: heat-dissolve molecularly distilled monoglyceride and anhydrous butter, stir high emulsification stability soybean protein, skimmed milk powder, and guar gum evenly, add appropriate amount of hot water, add dissolved sucros...

Embodiment 2

[0060] A kind of preparation method of low fat high stability soybean ice cream, raw material consumption is as follows (100g): high emulsification stability soybean protein 6g; Skim milk powder 9g; Anhydrous cream 5g; Sucrose 20g; Xanthan gum 0.2g; Ester 0.2g; water 59.6g.

[0061] (1) Preparation of high-stability soybean protein: use soybean protein isolate as raw material, use papain (enzyme activity 800,000 U / g, substrate concentration 5%, enzyme / substrate = 3%) to hydrolyze for 30 minutes to achieve hydrolysis The hydrolyzed sample was added with transglutaminase (enzyme activity 100U / g, enzyme / substrate = 2.5%) to cross-link for 1 hour after deactivating the enzyme, and obtained by spray drying after deactivating the enzyme.

[0062] (2) Raw material pretreatment: heat-dissolve molecularly distilled monoglyceride and anhydrous butter, stir high-stability soybean protein, skimmed milk powder, and xanthan gum into an appropriate amount of hot water, add dissolved sucrose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com