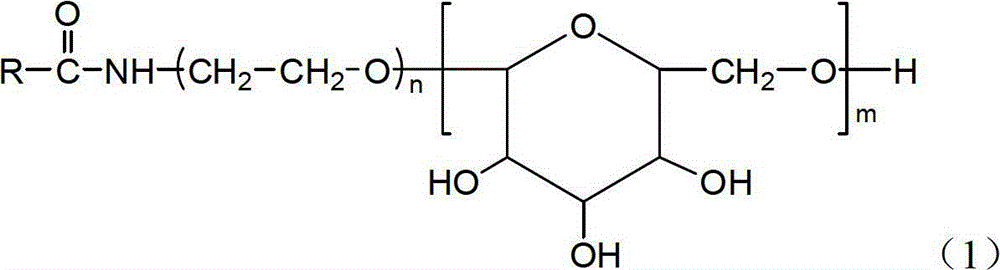

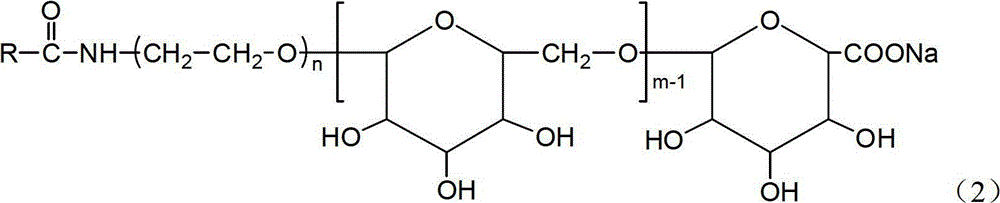

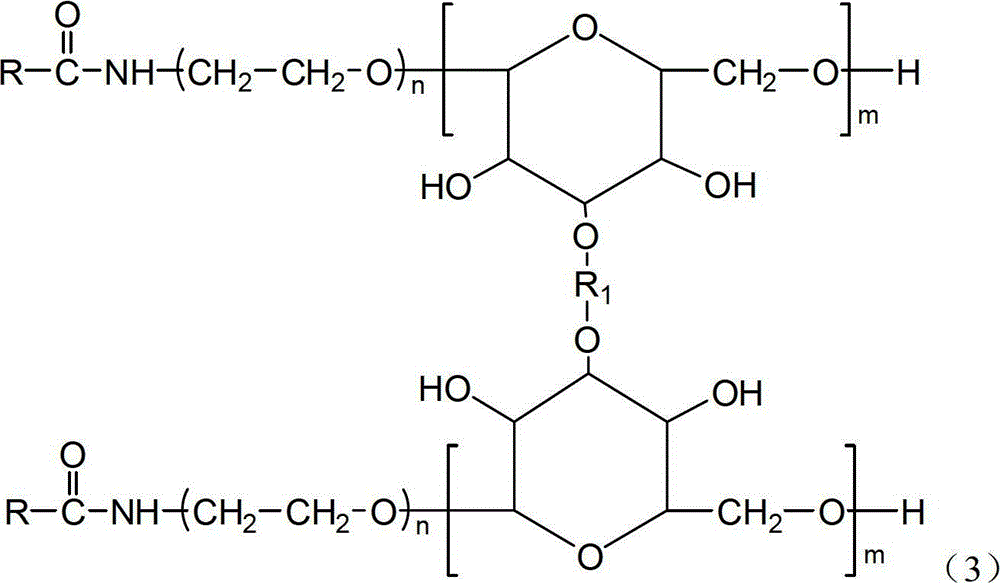

Surfactant composition and preparation method thereof

A technology for surfactants and mixtures, which is applied in the field of surfactant mixtures containing alkyl glycoside derivatives, can solve the problems of high cost, high production cost, failure to meet requirements, moderate cost, etc., and achieve production cost reduction, equipment Small investment, strong ability to remove oil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The corn stalks are loosely packaged with a baler, and the corn stalks are crushed by a grinder and transported to the storage bin. From the storage bin, the corn stalk powder is transported to a 4000kg metering tank through a conveyor belt, and then the corn stalk powder is put into the low-carbon In the alcohol glucosidation reaction kettle (1# kettle), add 16,000kg of ethylene glycol through a metering pump, add 32kg of weighed catalyst p-toluenesulfonic acid, and react for 1.5 hours at a temperature of 160°C; transfer the reacted material to In the centrifuge, separate the liquid phase material; transfer the liquid material to 1# storage tank for storage, then wash with 800kg, 70°C water for 15 minutes, centrifuge and dehydrate for 10 minutes, store the washed water in 2# storage tank, repeat This operation is washed 3 times in total. The solid material after water washing is dried by a drum dryer and packed into storage; the eluted aqueous solution is dehydrated and...

Embodiment 2

[0082]The corn stalks are loosely packaged with a baler, and the corn stalks are crushed by a grinder and transported to the storage bin. From the storage bin, the corn stalk powder is transported to a 4000kg metering tank through a conveyor belt, and then the corn stalk powder is put into the low-carbon In the alcohol glucosidation reaction kettle (1# kettle), add 15,000kg of ethylene glycol through a metering pump, add 30kg of weighed catalyst p-toluenesulfonic acid, and react for 2 hours at a temperature of 160°C; transfer the reacted material to In the centrifuge, the liquid phase material is separated, and the liquid material is transferred to the 1# storage tank for storage, then washed with 800kg, 70°C water for 15 minutes, centrifuged for 10 minutes, and the washed water is stored in the 2# storage tank, repeat This operation is washed 3 times in total. The solid material after water washing is dried by a drum dryer and packed into storage; the eluted aqueous solution i...

Embodiment 3

[0101] The corn stalks are loosely packaged with a baler, and the corn stalks are crushed by a grinder and transported to the storage bin. From the storage bin, the corn stalk powder is transported to a 4000kg metering tank through a conveyor belt, and then the corn stalk powder is put into the low-carbon In the alcohol glucosidation reaction kettle (1# kettle), add 18000kg of ethylene glycol through a metering pump, add 35kg of weighed catalyst p-toluenesulfonic acid, and react for 1.5 hours at a temperature of 150°C; transfer the reacted material to In the centrifuge, separate the liquid phase material, transfer the liquid material to 1# storage tank for storage, then wash with 600kg, 70°C water for 15 minutes, centrifuge for 10 minutes, store the washed water in 2# storage tank, repeat This operation is washed 3 times in total. The solid material after water washing is dried by a drum dryer and packed into storage; the eluted aqueous solution is dehydrated and concentrated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com