Recycling and processing device for painted plastic parts

A technology for recycling and processing plastic parts, which is applied in the field of recycling and processing scrapped plastic parts. It can solve problems such as secondary pollution, severe foaming, and high pressure in wastewater treatment, and achieve the goals of reducing pollution, reducing space occupation, and increasing gas flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

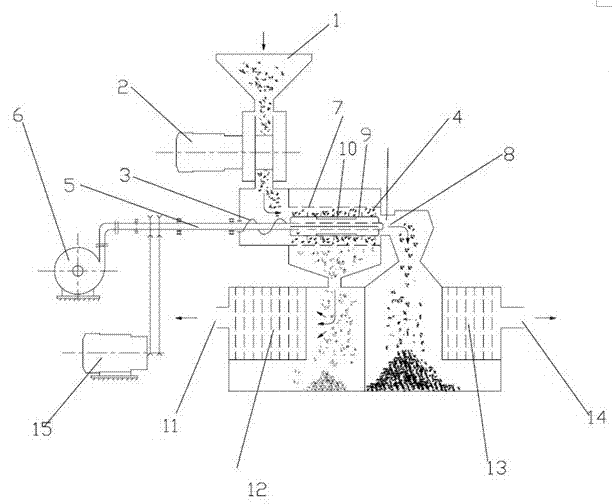

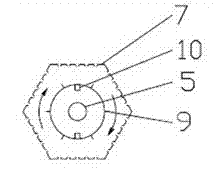

[0024] Embodiment one: see figure 1 and 2 Shown is a recycling device for painted plastic parts, the painted plastic parts are plastic particles, the recycling device includes a feeding mechanism, a separation mechanism, a plastic particle recycling mechanism and a waste recycling mechanism, the feeding mechanism It includes a quantitative feeder 2 and a screw feeder 3, the separation mechanism is a rotary friction separator 4, the screw feeder is coaxially arranged with the friction separator, and its rotating shaft is a hollow shaft 5, hollow One end of the shaft 5 is connected to the air supply mechanism. The part of the hollow shaft located in the friction separator has air outlet holes distributed on the shaft wall. A mesh dust removal sieve 7 is arranged around the outer periphery of the friction separator. The mesh dust removal sieve 7 The outer peripheral space communicates with the waste material recovery mechanism; the other end of the friction separator opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com