Bimetallic composite plate material and manufacturing process thereof

A composite sheet and manufacturing process technology, which is applied in the sheet manufacturing process, bimetal composite sheet, and the manufacturing process field of manufacturing the above bimetal composite sheet, can solve the limitation of popularization and application of bimetal composite sheet, reduction of polymer film bonding surface, Unable to guarantee bond strength and other issues, to achieve excellent creep resistance, stable overall performance, and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

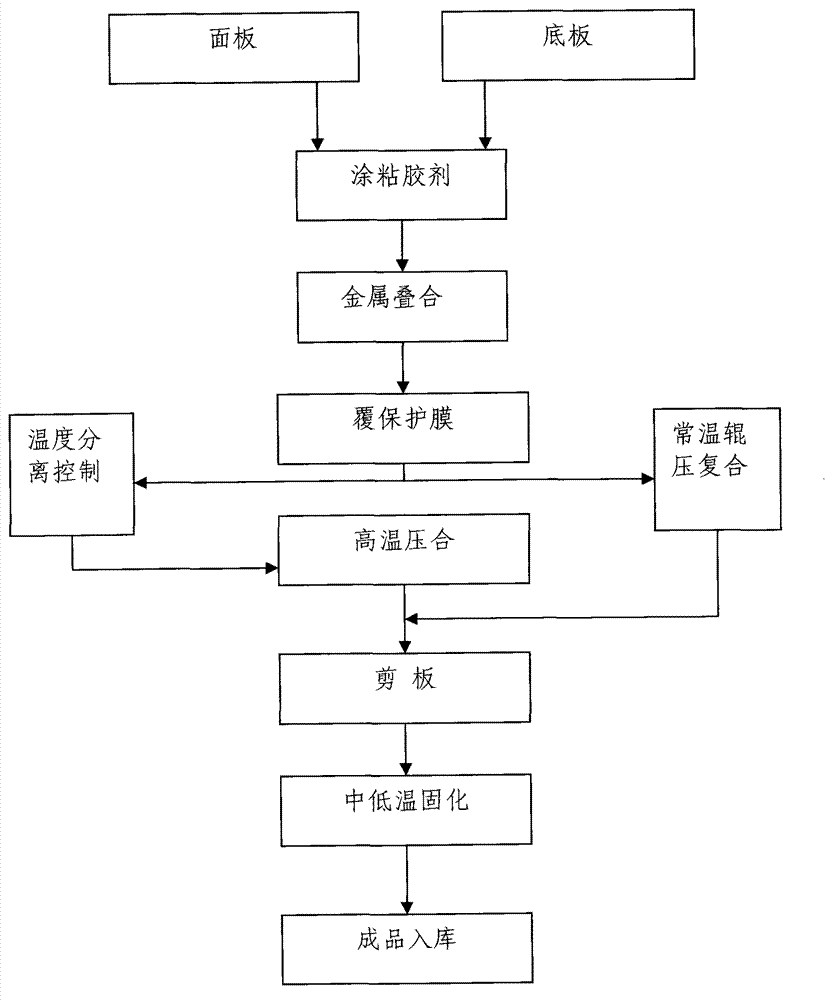

[0043] Include the following steps:

[0044] a. Apply polyurethane adhesive evenly between the surface metal and the bottom metal;

[0045] b. Superimposed surface metal and underlying metal;

[0046] c. Protective film on the opposite metal layer;

[0047] d. The surface layer metal and the bottom metal are rolled together at room temperature;

[0048] e. Cut board;

[0049] f. Curing at low temperature in the range of 35°C-55°C.

no. 2 example

[0051] a. Apply polyurethane adhesive evenly between the surface metal and the bottom metal;

[0052] b. Superimposed surface metal and underlying metal;

[0053] c. Protective film on the opposite metal layer;

[0054] d. Divide 8 heating temperature zones on the upper and lower sides of the composite board, and each two are paralleled as a group of synchronous control, and the group is gradually heated to 80°C for heating and rolling compounding;

[0055] e. Cut board;

[0056] f. Curing at low temperature in the range of 35°C-55°C.

no. 3 example

[0058] a. Apply polyurethane adhesive evenly between the surface metal and the bottom metal;

[0059] b. Superimposed surface metal and underlying metal;

[0060] c. Protective film on the opposite metal layer;

[0061] d. Divide 8 heating temperature zones on the upper and lower sides of the composite board, and each two are paralleled as a group of synchronous control, and the grouping is gradually heated to 100 °C for heating and rolling compounding;

[0062] e. Cut board;

[0063] f. Curing at low temperature in the range of 35°C-55°C.

[0064] The polyurethane adhesive base material described in the above steps is mainly modified polyphenylene oxide (MPPO), supplemented by polystyrene (PS).

[0065] In the process flow, the adhesive is cast and coated on the bimetal composite interface, and under heating and rolling at room temperature or lower than 100°C, sufficient initial bonding force can be produced within 150 seconds to meet the needs of the production process an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com