Preparation method of multistage-structured flower-shaped molybdenum dioxide

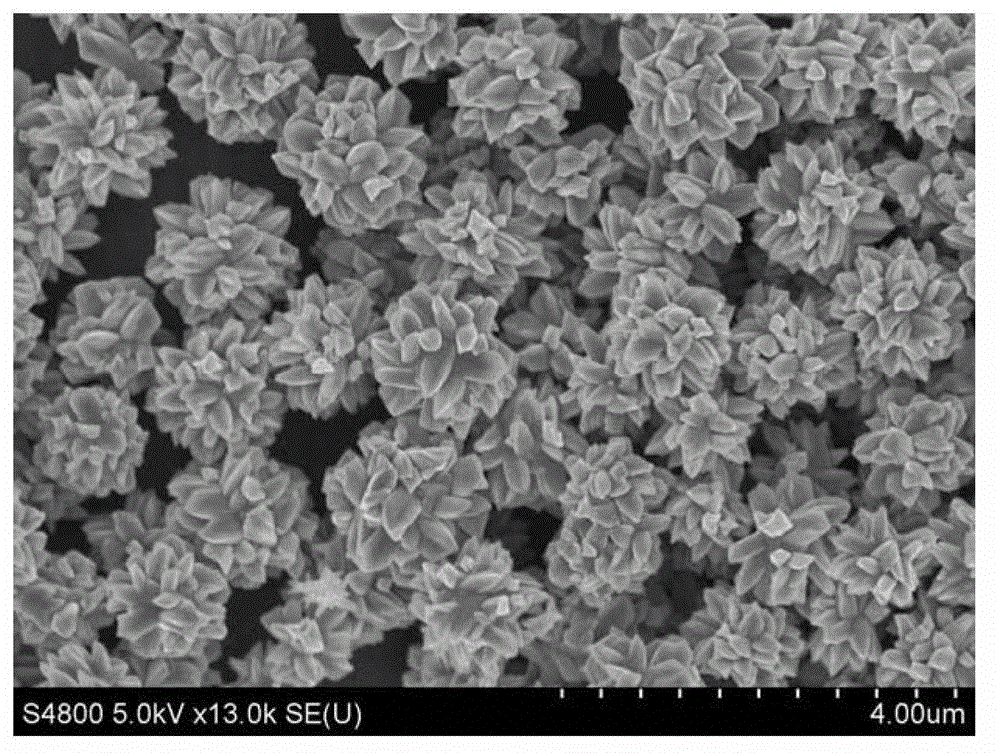

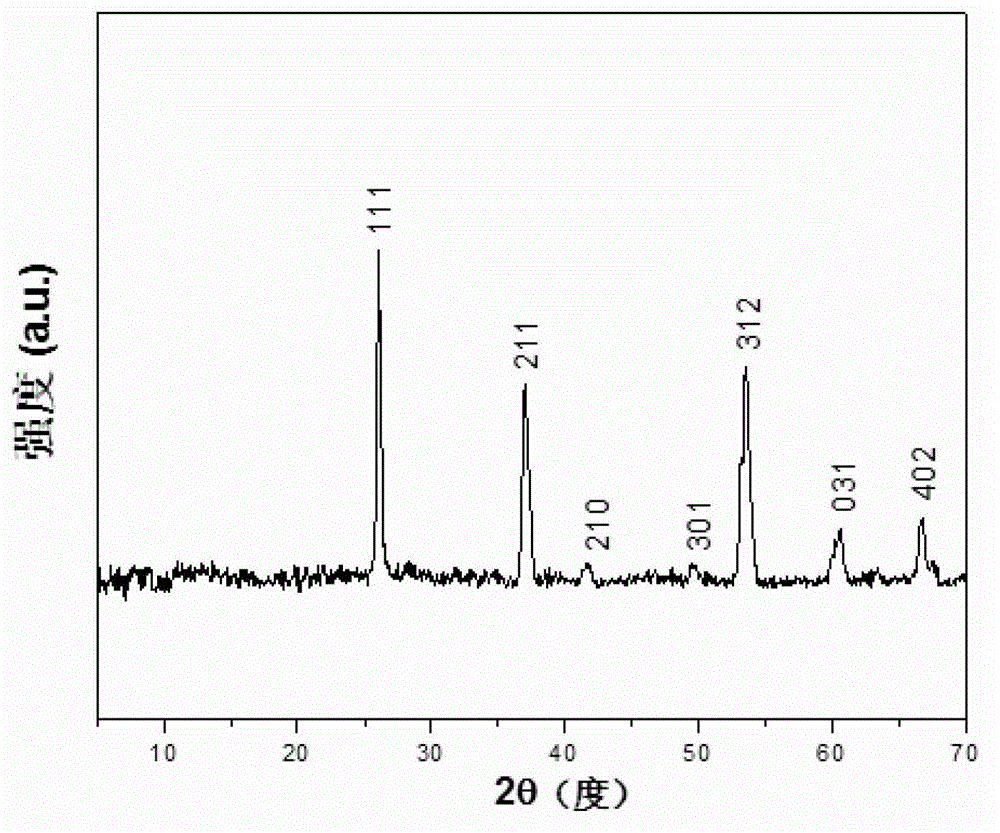

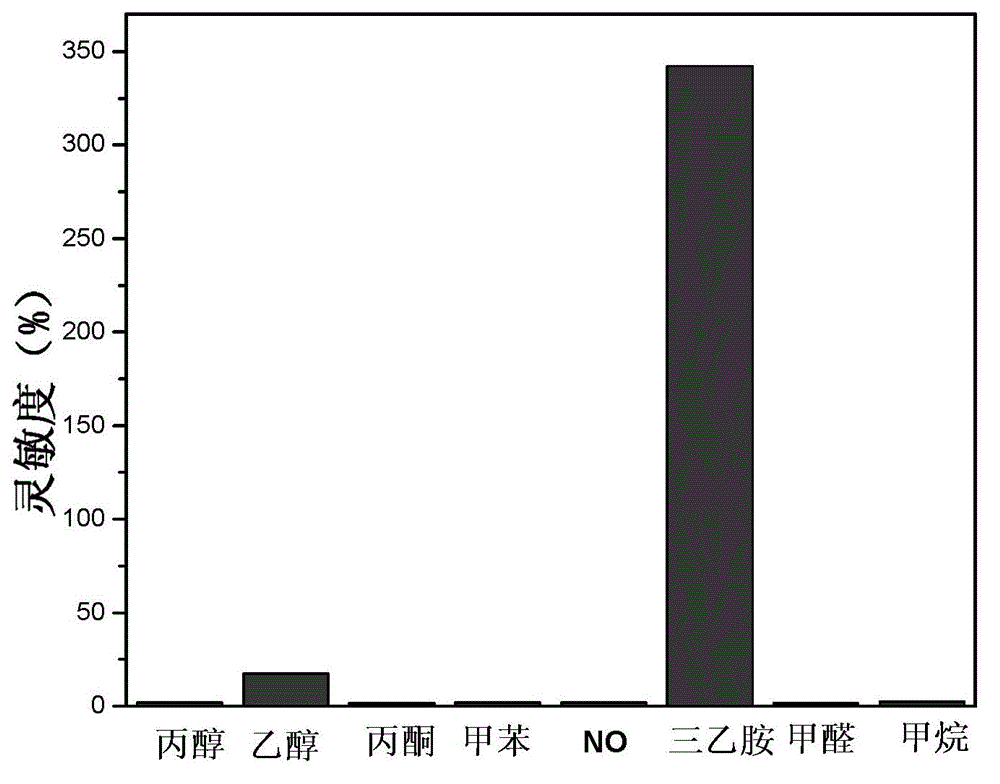

A molybdenum dioxide and flower-like technology is applied in the field of preparation of molybdenum dioxide, which can solve the problems of poor sensitivity of molybdenum trioxide and poor gas sensitivity of triethylamine gas, and achieve the effects of good monodispersity and good gas sensitivity characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of multi-level structure flower-shaped molybdenum dioxide of this embodiment is carried out according to the following steps:

[0017] 1. According to the volume ratio of 1:0.59~2.5, add hydrogen peroxide dropwise into the methanol solution of oxymolybdenum acetylacetonate, stir for 30 minutes to obtain a light yellow transparent solution, and transfer it to a 50mL reaction kettle, and heat it at 140~200°C Solvothermal reaction for 24h to obtain a black precursor;

[0018] 2. The precursor obtained in step 1 is washed with absolute ethanol and then vacuum-dried at 60-70° C. for 8-15 hours to obtain multi-level flower-like molybdenum dioxide with a vacuum degree of 0.05 MPa-0.07 MPa.

[0019] Wherein the mass concentration of hydrogen peroxide in the step 1 is 30%; the concentration of the methanol solution of oxymolybdenum acetylacetonate is 0.016mol / L-0.035mol / L.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, hydrogen peroxide is added dropwise to the methanol solution of oxymolybdenum acetylacetonate at a volume ratio of 1:0.59. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, hydrogen peroxide is added dropwise to the methanol solution of oxymolybdenum acetylacetonate at a volume ratio of 1:0.6. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com