Electrochemical combined coking wastewater deep treatment process and equipment thereof

A coking wastewater and advanced treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased desalination costs, pipe network and equipment corrosion, pollutant transfer, etc. problems, to achieve the effect of strong engineering application value, reasonable equipment design, and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

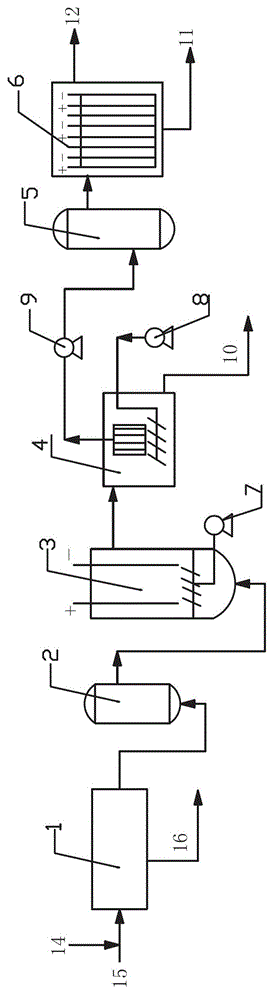

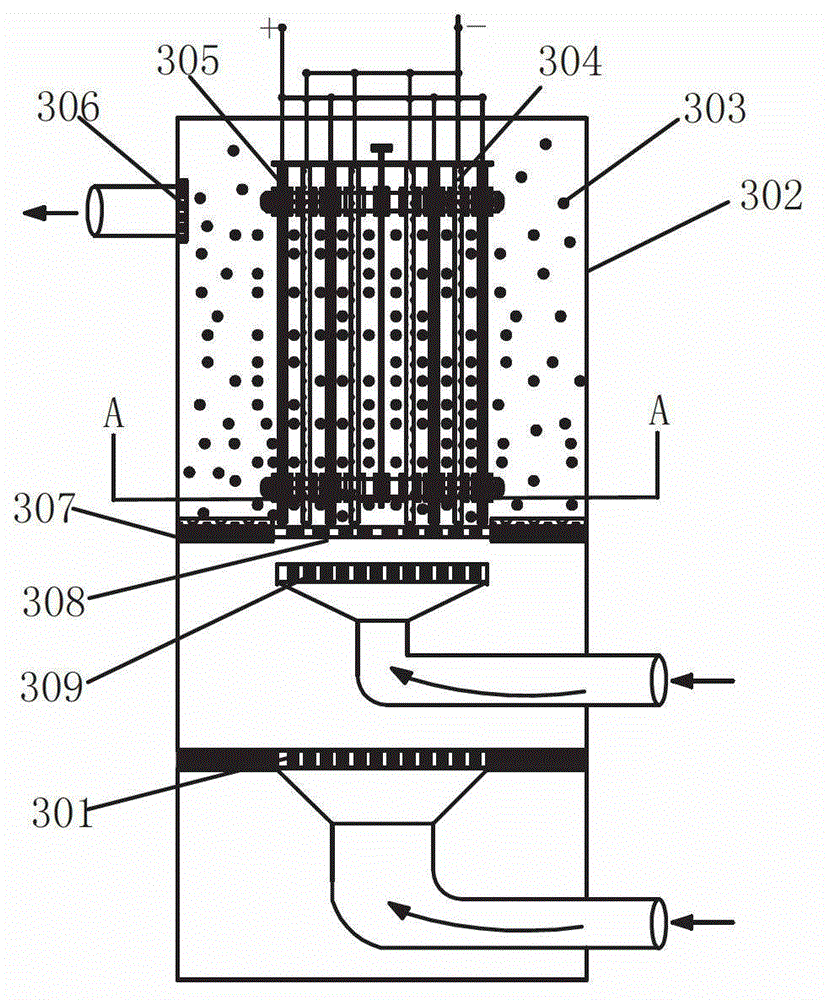

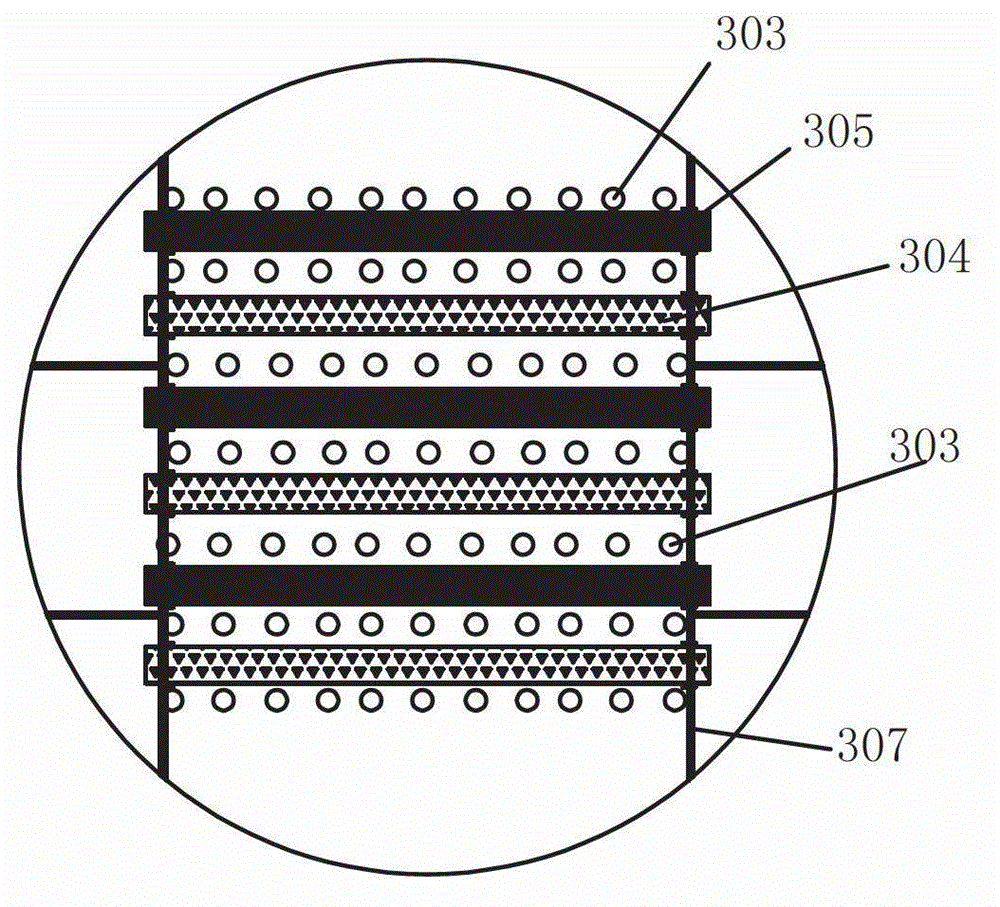

[0034] Such as figure 1As shown, the electrochemical combined coking wastewater advanced treatment equipment of the present invention includes a mixed sedimentation tank 1, a multimedia filter 2, a fluidized bed three-dimensional electrode reactor 3, an MBR membrane bioreactor 4, a security filter 5 and an electric The adsorption device 6, the coking wastewater outlet of the mixed sedimentation tank 1 is connected to the inlet of the multimedia filter 2, the outlet of the multimedia filter 2 is connected to the wastewater input end of the fluidized bed three-dimensional electrode reactor 3, and the fluidized bed three-dimensional electrode reaction The air input end of the device 3 is connected with the blower 7, the waste water output end of the fluidized bed three-dimensional electrode reactor 3 is connected with the water inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com