Preparation method and application of sulfhydryl chitosan/activated carbon composite functional membrane

A composite function, activated carbon technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of complicated treatment process, unsatisfactory treatment effect, and increased treatment cost, and achieve mechanical strength. Good, cost-reduced, simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

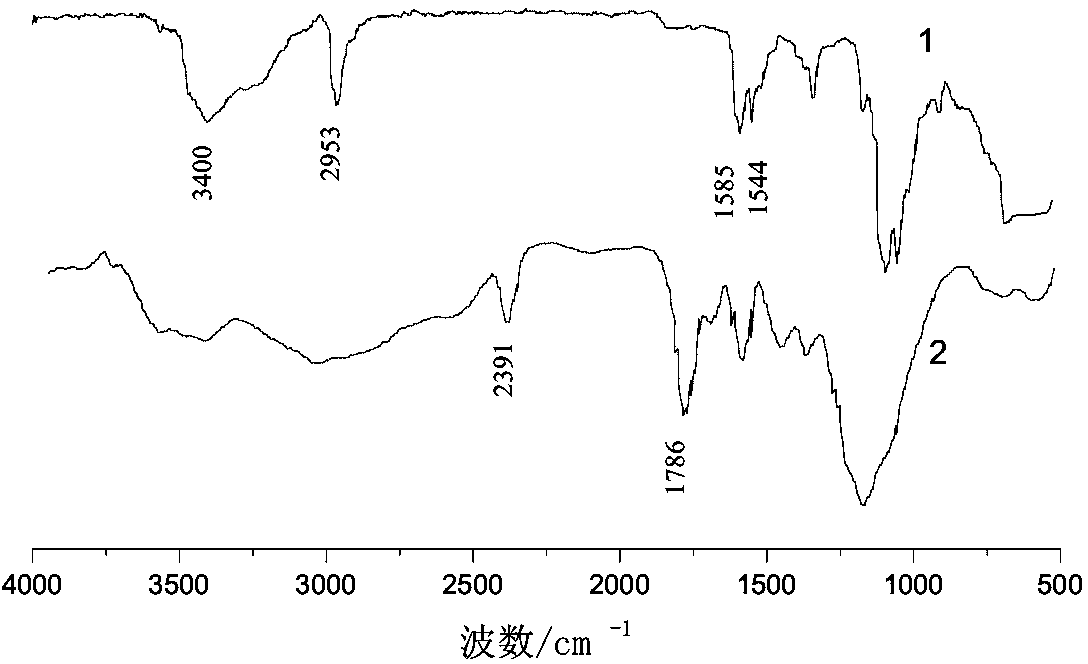

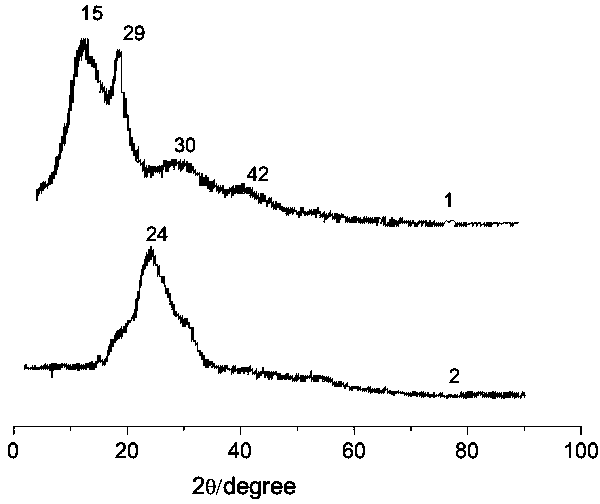

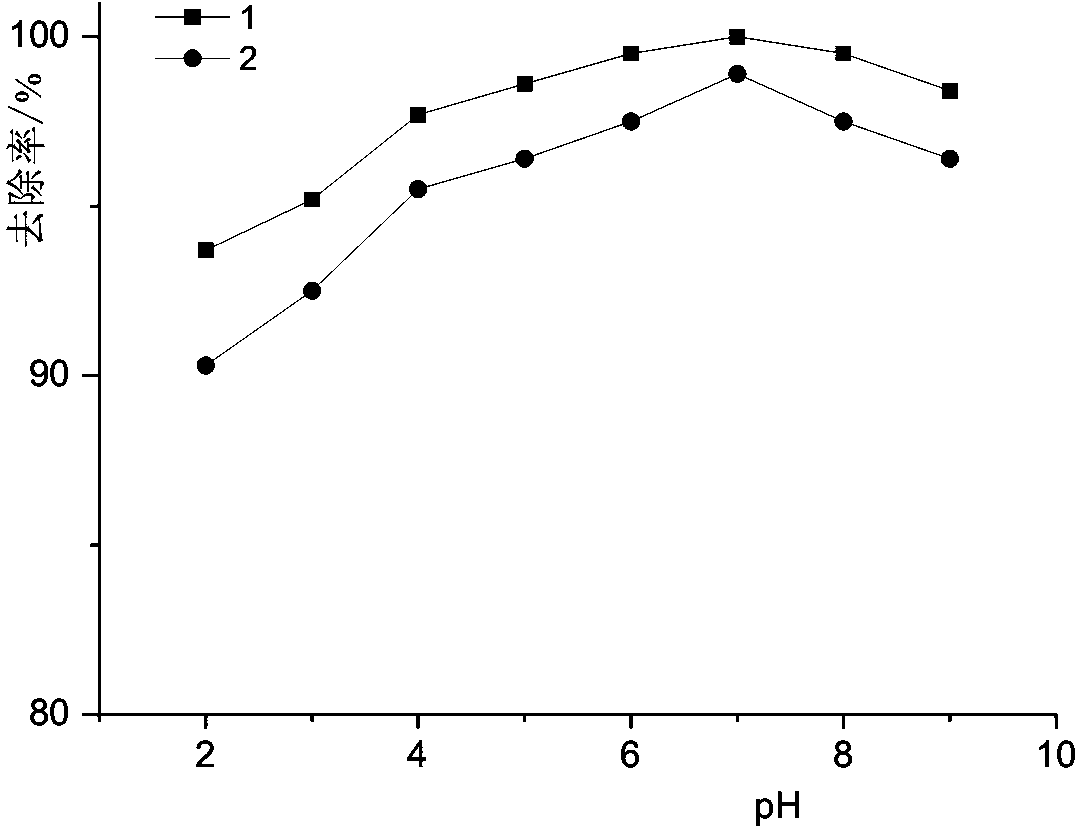

[0020] This example is the preparation of mercapto-chitosan / activated carbon composite functional membrane (CS-SH / C). The specific process is: add 10g chitosan (CS) to 240g of 0.50mol L -1 In the acetic acid aqueous solution, stirring and dissolving to obtain the chitosan acetic acid solution; take the powdered activated carbon, treat it with 10% nitric acid aqueous solution, heat and stir in a boiling water bath for 2 hours, filter, wash with deionized water until neutral, and dry at 120°C for 5 h, to obtain dry activated carbon; add 1 g of the treated dry activated carbon to the chitosan acetic acid solution, stir evenly to obtain the casting solution; take 6 mL of the casting solution and add it to a circular polypropylene mold with a diameter of 5 cm, and keep the temperature at 60 °C , when the volatilization weight loss is about 50%, soak the membrane in 1mol·L -1 NaOH aqueous solution coagulation bath, after coagulation in the coagulation bath for 24h, rinse the membra...

Embodiment 2

[0022] This example is the preparation of mercapto-chitosan / activated carbon composite functional membrane (CS-SH / C). The specific process is: add 10g chitosan (CS) to 300g of 0.50mol L -1 acetic acid aqueous solution, stirring and dissolving to obtain chitosan acetic acid solution; take powdered activated carbon, treat with 10% nitric acid, heat and stir in a boiling water bath for 3 hours, filter, wash with deionized water until neutral, and dry at 120°C for 5 h, to obtain dry activated carbon; add 2 g of the treated dry activated carbon to the chitosan acetic acid solution, and stir evenly to obtain a casting solution. Take 6mL of the casting solution and add it to a circular polypropylene mold with a diameter of 5cm, keep the temperature at 60°C, and when the volatilization loses about 50%, soak the film in 1mol·L -1NaOH aqueous solution coagulation bath, after coagulation in the coagulation bath for 24h, rinse the membrane with distilled water until neutral to obtain chi...

Embodiment 3

[0024] This example is the preparation of mercapto-chitosan / activated carbon composite functional membrane (CS-SH / C). The specific process is: add 10g chitosan (CS) to 400g of 0.50mol L -1 acetic acid aqueous solution, stir and dissolve to obtain chitosan acetic acid solution; take powdered activated carbon, treat it with 10% aqueous nitric acid solution, heat and stir in a boiling water bath for 3 hours, filter, wash with deionized water until neutral, and dry at 120°C 5 h to obtain dry activated carbon; add 2 g of the treated dry activated carbon to the chitosan acetic acid solution and stir evenly to obtain a casting solution. Take 6mL of the casting solution and add it to a circular polypropylene mold with a diameter of 5cm, keep the temperature at 60°C, and when the volatilization loses about 50%, soak the film in 1mol·L -1 NaOH aqueous solution coagulation bath, after coagulation in the coagulation bath for 24h, rinse the membrane with distilled water until neutral to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com