Environmentally-friendly antibacterial powder coating

A powder coating, environmental protection technology, applied in the direction of powder coating, epoxy resin coating, polyester coating, etc., can solve the problems of lack of antibacterial ability, single antibacterial function, antibacterial effect decline, etc., to achieve good human health and antibacterial effect Good, reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Accurately weigh the raw materials used to prepare the environment-friendly antibacterial powder coating according to the weight percentage of the following components:

[0027] Polyester: 30%; Epoxy resin: 40%; Leveling agent: 1.5%; Brightener: 0.5%; Negative ion generator: 16%; Coupling agent: 12%; 40-75.

[0028] Put the above-mentioned weighed raw materials into a high-speed mixer for pre-mixing for 10 to 15 minutes, then put the obtained mixture into an extruder and extrude at a temperature of 120°C to 130°C, and then crush it into tablets , and then crushed into powder particles with a particle size of 30-35 microns by an ACM micro-pulverizer, and then pass the powder particles through a 140-mesh sieve, inspected and packaged to obtain a finished environmental protection antibacterial powder coating.

[0029] The environment-friendly antibacterial powder coating obtained above is sprayed by high-voltage electrostatic spraying, with an average thickness of 70-80 m...

Embodiment 2

[0031] Accurately weigh the raw materials used to prepare the environment-friendly antibacterial powder coating according to the weight percentage of the following components:

[0032] Polyester: 40%; Epoxy resin: 30%; Leveling agent: 0.5%; Brightener: 1.5%; Negative ion generator: 16%; Coupling agent: 12%; 40-75.

[0033] Put the above-mentioned weighed raw materials into a high-speed mixer for pre-mixing for 10 to 15 minutes, then put the obtained mixture into an extruder and extrude at a temperature of 120°C to 130°C, and then crush it into tablets , and then crushed into powder particles with a particle size of 30-35 microns by an ACM micro-pulverizer, and then pass the powder particles through a 140-mesh sieve, inspected and packaged to obtain a finished environmental protection antibacterial powder coating.

[0034] The environment-friendly antibacterial powder coating obtained above is sprayed by high-voltage electrostatic spraying, with an average thickness of 70-80 m...

Embodiment 3

[0036] Accurately weigh the raw materials used to prepare the environment-friendly antibacterial powder coating according to the weight percentage of the following components:

[0037] Polyester: 40%; Epoxy resin: 40%; Leveling agent: 1.0%; Brightener: 1.0%; Negative ion generator: 10%; Coupling agent: 8.0%; 40-75.

[0038] Put the above-mentioned weighed raw materials into a high-speed mixer for pre-mixing for 10 to 15 minutes, then put the obtained mixture into an extruder and extrude at a temperature of 120°C to 130°C, and then crush it into tablets , and then crushed into powder particles with a particle size of 30-35 microns by an ACM micro-pulverizer, and then pass the powder particles through a 140-mesh sieve, inspected and packaged to obtain a finished environmental protection antibacterial powder coating.

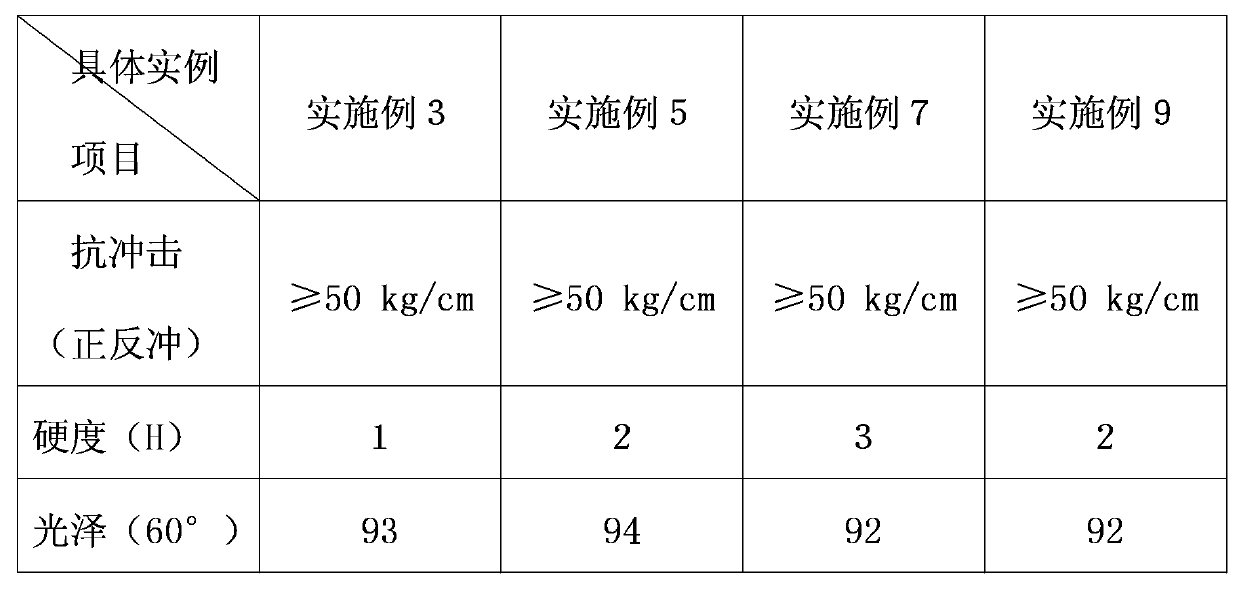

[0039] The environment-friendly antibacterial powder coating obtained above is sprayed by high-voltage electrostatic spraying, with an average thickness of 70-80 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com