Tricone bit oil storage compensation pressure balancing system

A balancing system and tricone technology, which are applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of reducing the overall service life of the roller-cone bit, complicated processing, damage to the oil storage bag, etc., and achieve simple structure and integrity. Good, overall height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

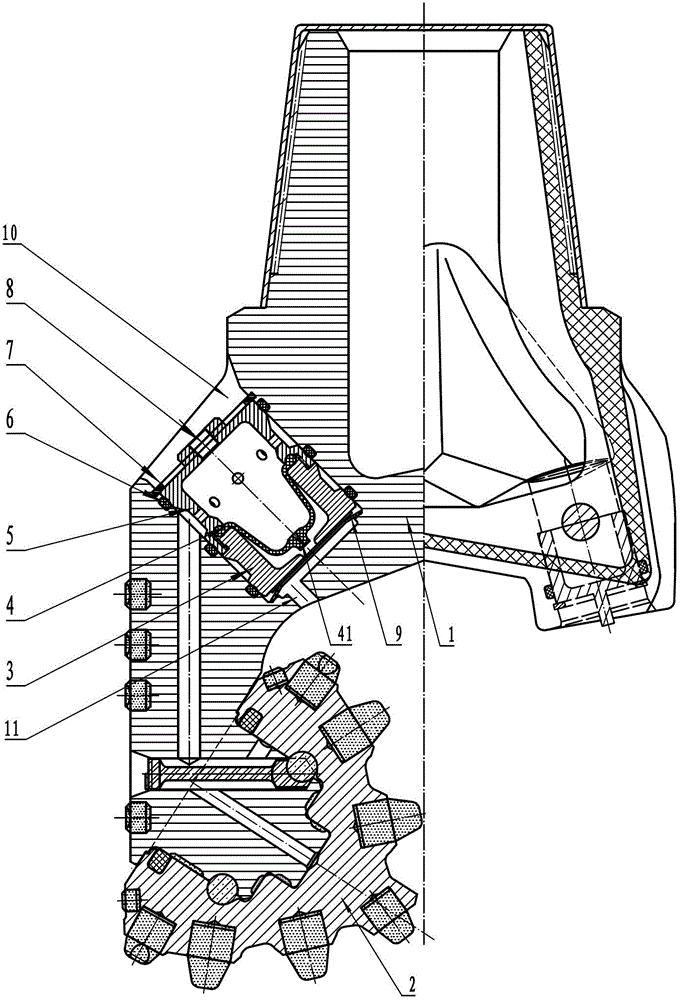

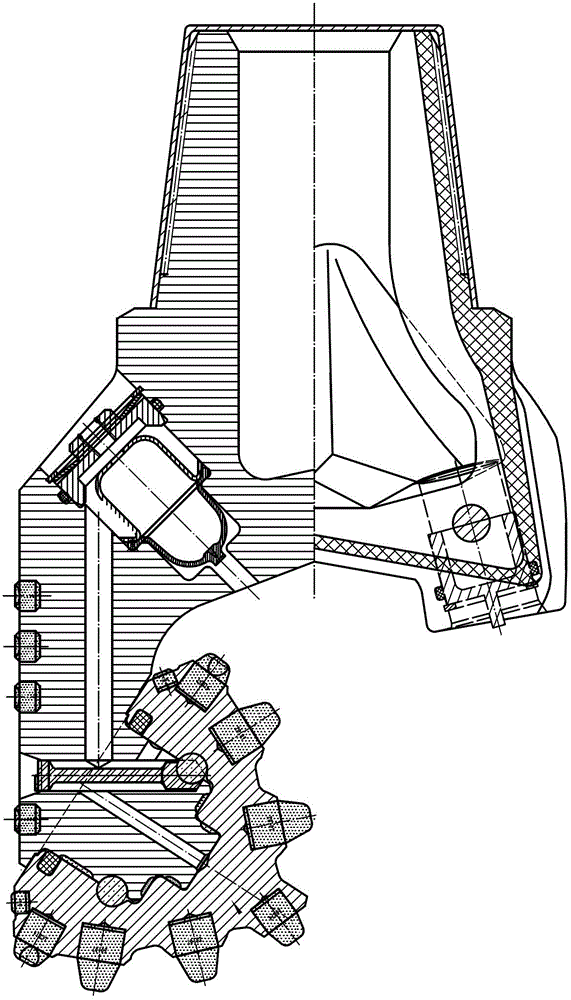

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. like figure 1 As shown, a tricone bit oil storage compensation pressure balance system includes a palm oil hole 10 opened on the tooth palm 1, an oil storage bag 4 is arranged in the tooth palm oil hole, and a pinhole is arranged at the bottom of the oil storage bag 41. The pinholes are staggered with the pressure transmission holes 11 provided on the palms. The palm oil hole communicates with the inside of the cone 2 through a channel to provide and compensate lubricating grease. When working, when the oil storage bag is concave inward due to a large external pressure, the pinhole is in a closed state due to the elasticity of the rubber; when the external pressure is less than the grease pre-pressure in the oil storage hole, the oil storage bag The outside of the hole is raised, the pinhole is in an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com