Preparation method of graphene-based nanocomposite

A nanocomposite, graphene-based technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as difficulty in quantitatively controlling the loading of metal oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the preparation method of a kind of graphene-based nano-composite material of this embodiment is specifically prepared according to the following steps:

[0023] 1. Graphene oxide was prepared by modified Hummers method;

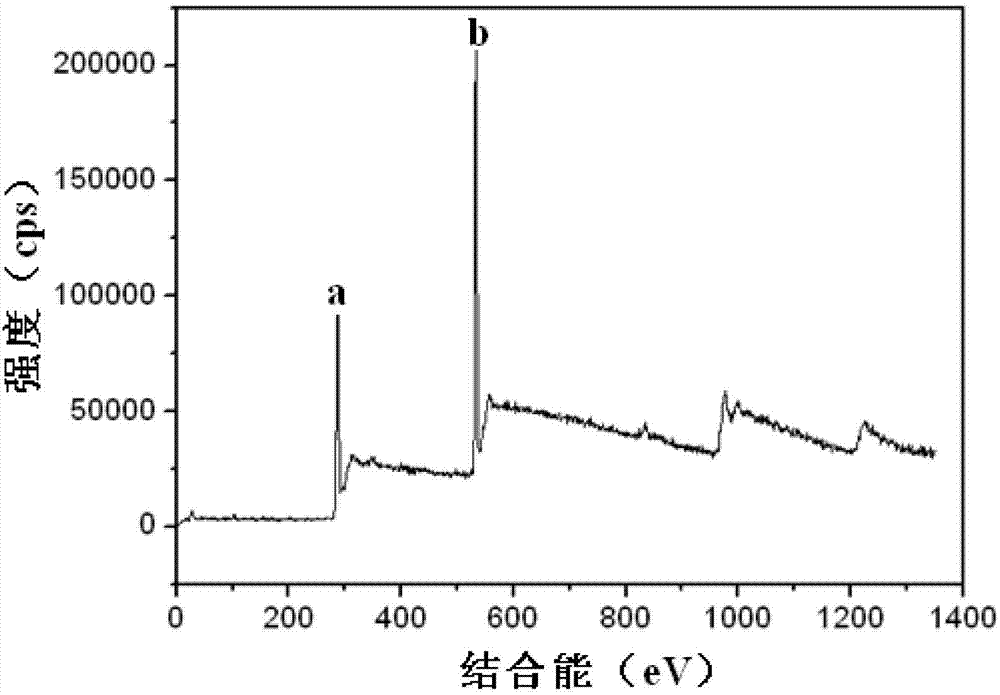

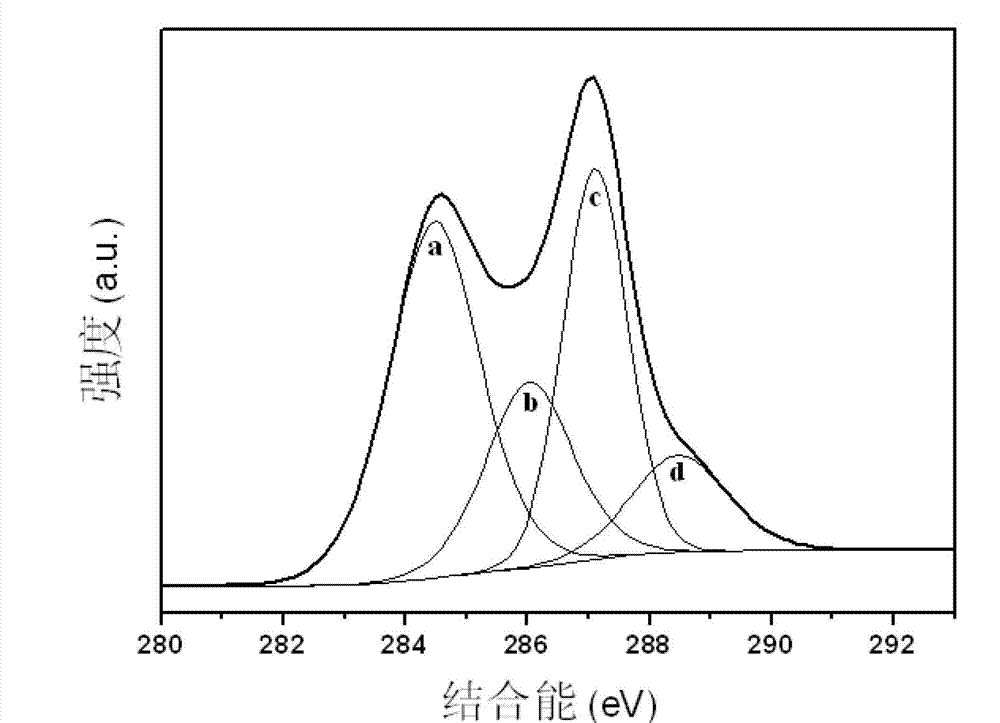

[0024] Two, carry out XPS test analysis to the graphene oxide prepared in step 1, and fit C1s peak, obtain the percentage composition of the amount of substance of graphene oxide surface C-C, C-O, C=O and C(O)O respectively a , b, c and d, the percentage composition of the amount of substances containing oxygen-containing functional groups on the surface of graphene oxide is drawn as b+c+d;

[0025] 3. Use an ultrasonic cleaner to disperse the graphene oxide prepared in e mol step 1 into deionized water, and prepare a graphene oxide dispersion with a concentration of 0.1mg / mL~10mg / mL, wherein the control frequency is 40kHz~60kHz, Dispersion time is 30min~300min;

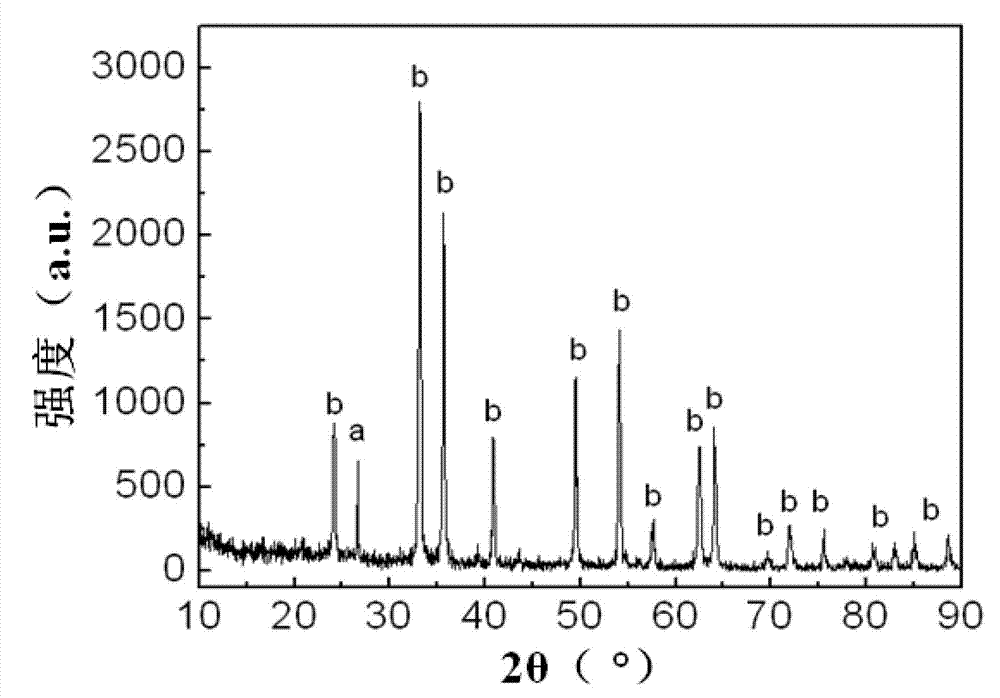

[0026] 4. Weighing The precursor of the metal oxide intende...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 3, a graphene oxide dispersion with a concentration of 0.2 mg / mL-8 mg / mL is prepared. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the precursor of the metal oxide in step 4 is FeCl 2 4H 2 O, Co(NO 3 ) 2 ·6H 2 O or SnCl 2 2H 2 O and Mn(CH 2 COO) 2 4H 2 O. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com