Composite cheese liver flavor attractant and preparation method thereof

A technology of compound fragrance and food attractant, applied in application, animal feed, animal feed and other directions, can solve the problems of increasing the health and safety risk of pet food, and achieve the safety of food attractant, no irritation, and good flavor coordination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

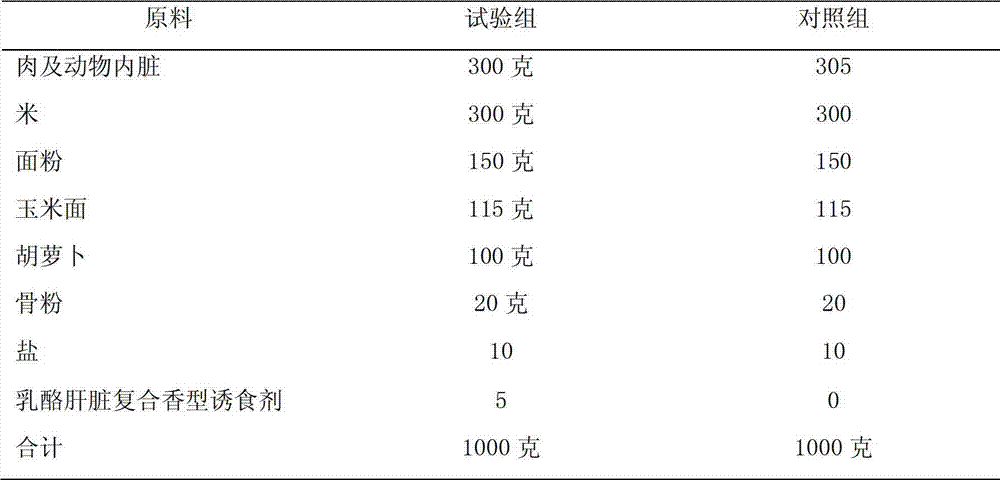

Examples

Embodiment 1

[0026] The formula is: natural butter hydrolyzate: 7 parts; fresh pork liver hydrolyzate: 30 parts; yeast extract (YE): 2.5 parts; xylose: 3 parts; cysteine hydrochloride: 1.5 parts; Vitamin B 1 : 2 parts; glutamic acid: 3 parts; dextrin: 25 parts; water: 26 parts.

[0027] The preparation process is as follows: A. The fresh pork liver is pulverized and homogenized in a stainless steel tissue homogenizer at room temperature and passed through 200 meshes, then transferred to a stainless steel enzymatic hydrolysis tank, and papain is added to 2% of the total mass of the homogenate for enzymolysis at 45°C for 10 Obtain fresh pork liver enzymolyzate within 1 hour; B, add 2% compound flavor enzyme of the total mass of natural butter after melting the natural butter, and enzymolyze it in a stainless steel biological enzymolysis tank at 45°C for 6 hours to obtain natural butter enzymolyzate; C, mix the above fresh Pig liver hydrolyzate and natural butter hydrolyzate were added to ...

Embodiment 2

[0033] The formula is: natural cream hydrolyzate: 2 parts; fresh pig liver hydrolyzate: 40 parts; yeast extract (YE): 3.5 parts; xylose: 3.5 parts; cysteine hydrochloride: 1.5 parts; Vitamin B 1 : 2 parts; glutamic acid: 2 parts; dextrin: 30 parts; water: 15.5 parts.

[0034] The preparation process is as follows: A. The fresh pork liver is pulverized and homogenized in a stainless steel tissue homogenizer at room temperature and passed through 200 meshes, then transferred to a stainless steel enzymatic hydrolysis tank, and papain is added to 3% of the total mass of the homogenate for enzymolysis at 40°C9 Obtain fresh pork liver enzymolyzate in 1 hour; B, add the compound flavor enzyme of 1% of the total mass of natural butter after melting natural cream, and enzymolyze in stainless steel biological enzymolysis tank at 45°C for 6 hours to obtain natural butter enzymolyzate; C, mix the above Fresh pig liver enzymatic hydrolyzate and natural butter enzymatic hydrolyzate were ...

Embodiment 3

[0041] The formula is: natural butter hydrolyzate: 15 parts; fresh pork liver hydrolyzate: 55 parts; yeast extract (YE): 2 parts; xylose: 4 parts; cysteine hydrochloride: 2 parts; Vitamin B 1 : 2 parts; glutamic acid: 3 parts; dextrin: 2 parts; water: 15 parts.

[0042] The preparation process is as follows: A. The fresh pork liver is pulverized and homogenized in a stainless steel tissue homogenizer at room temperature and passed through 200 mesh, then transferred to a stainless steel enzymatic hydrolysis tank, and papain is added to 3% of the total mass of the homogenate for enzymolysis at 50°C for 12 Obtain fresh pork liver enzymolyzate within 1 hour; B, add the compound flavor enzyme of 3.5% of the total mass of natural butter after dissolving natural cream, enzymolyze in stainless steel biological enzymolysis tank at 50 ℃ for 10 hours to obtain natural butter enzymolyzate; C, mix the above Fresh pig liver enzymatic hydrolyzate and natural butter enzymatic hydrolyzate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com