General A-type foam extinguishing agent easy to degrade

A foam fire extinguishing agent, easily degradable technology, used in fire protection equipment and other directions, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

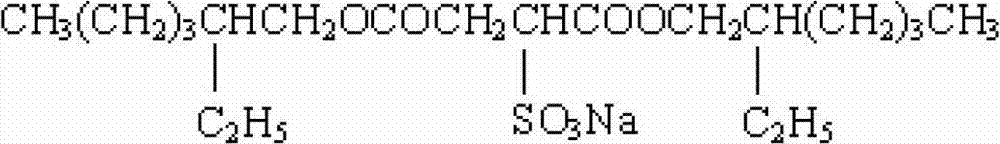

Method used

Image

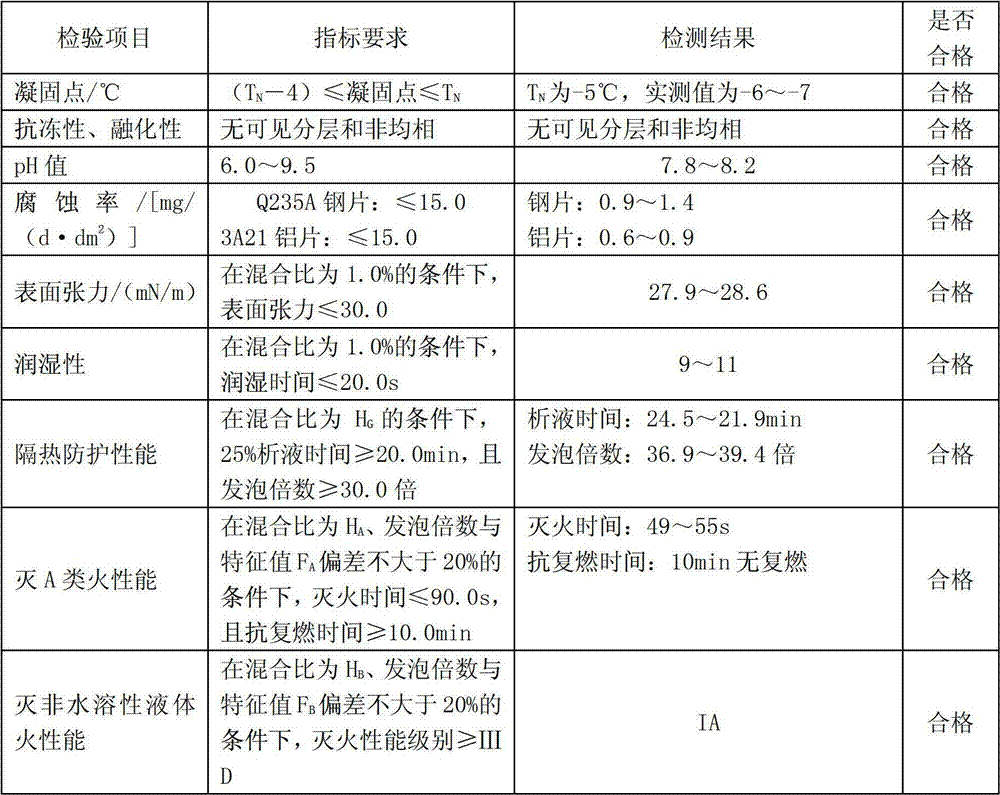

Examples

Embodiment 1

[0039] General-purpose easy-degradable Class A foam fire extinguishing agent, the weight percentage of each composition based on the total weight is: main foaming agent 8%, auxiliary foaming agent 20%, co-solvent 20%, foam stabilizer 0.1%, wetting and penetrating 0.1% agent, 0.2% corrosion inhibitor, 0.1% preservative, and the rest is water.

[0040] in:

[0041] The main blowing agent is a fatty alcohol sulfate, specifically sodium lauryl sulfate, ammonium lauryl sulfate or sodium octadecyl sulfate.

[0042] The secondary foaming agent is fatty alcohol polyoxyethylene ether sulfate, specifically sodium lauryl polyoxyethylene ether sulfate or sodium n-octyl alcohol polyoxyethylene ether sulfate.

[0043] Co-solvents are ethylene glycol methyl ether, ethylene glycol ethyl ether, ethylene glycol butyl ether, diethylene glycol methyl ether, diethylene glycol butyl ether, propylene glycol methyl ether, dipropylene glycol dimethyl ether, ethylene glycol, propylene glycol, One of ...

Embodiment 2

[0054] General-purpose easily degradable Class A foam fire extinguishing agent, the weight percentage content of each composition based on the total weight is: main foaming agent 12%, auxiliary foaming agent 15%, auxiliary solvent 25%, foam stabilizer 1%, wetting and penetrating 0.8% agent, 0.5% corrosion inhibitor, 1% preservative, and the rest is water.

[0055] in:

[0056] The primary blowing agent is a fatty alcohol sulfonate, specifically sodium dodecyl sulfate, potassium lauryl sulfate or sodium tetradecyl sulfate.

[0057] Auxiliary blowing agent is α-olefin sulfonate, specifically C 8-10 α-Olefin Sulfonate, C 12 α-Olefin Sulfonate or C 12-14 Alpha-Olefin Sulfonates.

[0058] Co-solvents are ethylene glycol methyl ether, ethylene glycol ethyl ether, ethylene glycol butyl ether, diethylene glycol methyl ether, diethylene glycol butyl ether, propylene glycol methyl ether, dipropylene glycol dimethyl ether, ethylene glycol, propylene glycol, Mix any one of ether and ...

Embodiment 3

[0064] General-purpose easy-degradable Class A foam fire extinguishing agent, the weight percentage of each composition based on the total weight is: 17% of the main foaming agent, 12% of the auxiliary foaming agent, 30% of the auxiliary solvent, 2% of the foam stabilizer, wetting and penetrating 1.2% agent, 1% corrosion inhibitor, 2% preservative, and the rest is water.

[0065] in:

[0066] The main foaming agent is α-sulfo fatty acid methyl ester sodium salt, specifically α-sulfo laurate methyl ester sodium salt or α-sulfo myristate methyl ester sodium salt.

[0067] The co-foaming agent is an alkyl glycoside, specifically C 8-10 APG, C 12 APG or C 12-14 APG.

[0068]Co-solvents are ethylene glycol methyl ether, ethylene glycol ethyl ether, ethylene glycol butyl ether, diethylene glycol methyl ether, diethylene glycol butyl ether, propylene glycol methyl ether, dipropylene glycol dimethyl ether, ethylene glycol, propylene glycol, A mixture of any ether and alcohol amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com