Process for forging end head of electric upset steel pull rod

A steel tie rod and electric upsetting technology is applied in the field of electric upsetting steel tie rod end forging technology. The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

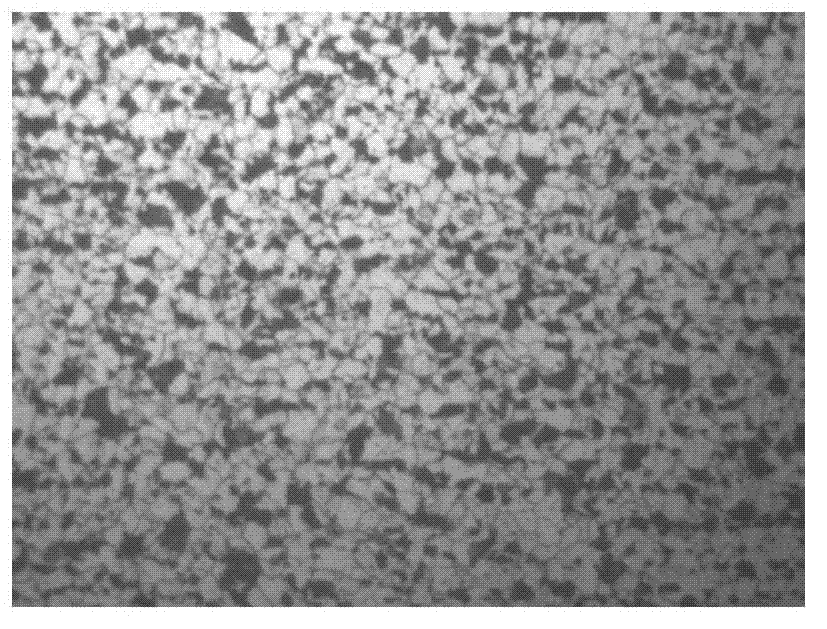

Image

Examples

Embodiment Construction

[0025] An electric upsetting steel tie rod end forging process, comprising the following steps:

[0026] a. Pouring steel ingot

[0027] The weight percentage of chemical composition in steel ingot is: 0.086%≤C≤0.150%, 1.30%≤Si≤1.40%, 1.20%≤Mn≤1.30%, trace ≤P≤0.033%, trace ≤S≤0.0260%, Li 0.11 -0.22%, 11.50% ≤ Cr ≤ 13.50%, trace ≤ B ≤ 0.0018%, the balance is iron and unavoidable impurities; the temperature of the cast ingot is lowered to 350°C, then heated to 670-760°C, and kept for 3 -5 hours, cool the furnace to 350°C, hold for 3 hours, then heat to 650-760°C, hold for 10 hours, cool to 400°C at 34°C / hour, then cool to 180°C at 20°C / hour;

[0028] b. Forging steps

[0029] (1) Put the upsetting end of the steel tie rod on the electric upsetting machine; (2) Clamp the upsetting ball electrode on the upsetting end, and the upsetting ball electrode faces the end of the upsetting end; (3) , heating the end to be upsetting by passing current through the electrode; (4), applying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com