Preparation method of high-strength fully-recycled coarse aggregate concrete

A technology for recycling coarse aggregate and concrete, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of low strength of fully recycled coarse aggregate concrete, which cannot meet engineering needs, and achieve improved strength. , Wide applicability, optimized interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1 selection of materials

[0035] Prioritize the selection of recycled coarse aggregate with a particle size range of 5-25mm and continuous grading. The water absorption rate is 3.23%, the moisture content is 1%, the crushing index is 12.51%, and the apparent density is 2290kg / m 3 . Xingda Class I fly ash grade, density 2300kg / m 3 . The sand is natural medium sand, with a moisture content of 5%-9%, a stone content of 15%-25%, and an apparent density of 2670kg / m 3 . Silver water superfine mineral powder (>=S95) apparent density 1227kg / m 3 . 42.5 grade Beishui cement, apparent density 3100kg / m 3 . Polycarboxylate high-efficiency water reducer (water reduction rate 28%) density 1130kg / m 3 , with a solid content of 10%. Water is tap water, density 1000kg / m 3 .

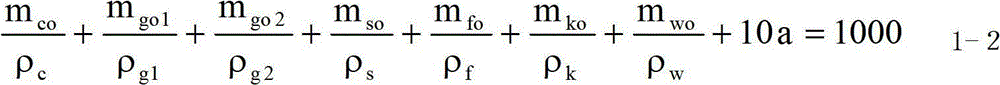

[0036] 2 Calculation of mix proportion of fully recycled coarse aggregate concrete

[0037] (1) Determine the sand rate

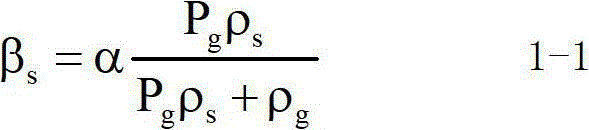

[0038] According to historical test experience, the actual sand rate is 46.9%. ...

Embodiment 2-3

[0054] According to step 2 of embodiment 1, embodiment 2-3 recycled coarse aggregate concrete 1m 3 Coordination such as Table 1-3; other steps with embodiment 1.

[0055] Table 1-3 Mix design of fully recycled coarse aggregate concrete (unit: kg)

[0056]

[0057] Table 1-4 Measured values of compressive strength of fully recycled coarse aggregate concrete

[0058] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com