Process for producing bioorganic fertilizer by utilizing fresh tobacco leaf

A bio-organic fertilizer and fresh tobacco leaf technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve problems such as pests and diseases, affect field operations, and farmers' losses, and achieve the effect of enhancing fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

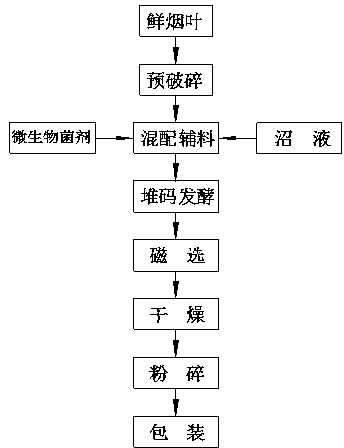

[0018] The present embodiment utilizes the technique of fresh tobacco leaf to produce bio-organic fertilizer, comprises the following steps:

[0019] a. Pre-crushing: use a crusher to crush the fresh tobacco leaves into 10mm blocks or strips;

[0020] B, mixing auxiliary material: take by weighing the fresh tobacco leaf after 1000kg crushing, add 200kg biogas slurry and 3kg microbial inoculum, described microbial inoculum comprises 70% Bacillus subtilis and 30% Bacillus licheniformis, stir after mixing, The water content of the material after stirring is 40%;

[0021] c. Stacking fermentation: stack the stirred mixture to a height of 1m and then carry out fermentation. After the fermentation temperature reaches 50°C, turn the pile 1-2 times a day. The fermentation temperature is controlled at 40°C, and the fermentation time is 9 days;

[0022] d. Magnetic separation: use a magnetic separator to remove metal impurities in the mixed material;

[0023] e. Drying: dry the mixed ...

Embodiment 2

[0028] The present embodiment utilizes the technique of fresh tobacco leaf to produce bio-organic fertilizer, comprises the following steps:

[0029] a. Pre-crushing: use a crusher to crush the fresh tobacco leaves into 20mm blocks or strips;

[0030] B, mixing auxiliary materials: take by weighing 1000kg broken fresh tobacco leaves, add 600kg biogas slurry and 1kg microbial inoculum, said microbial inoculum includes 50% Bacillus subtilis and 50% Bacillus licheniformis, stir evenly after mixing, The water content of the material after stirring is 60%;

[0031] c. Stacking fermentation: Stack the stirred mixture to a height of 1.5m and then ferment. After the fermentation temperature reaches 50°C, turn the pile 1-2 times a day, control the fermentation temperature at 59°C, and ferment for 7 days;

[0032] d. Magnetic separation: use a magnetic separator to remove metal impurities in the mixed material;

[0033] e, drying: dry the mixed material to a moisture content of 28%; ...

Embodiment 3

[0038] The present embodiment utilizes the technique of fresh tobacco leaf to produce bio-organic fertilizer, comprises the following steps:

[0039] a. Pre-crushing: use a crusher to crush the fresh tobacco leaves into 15mm blocks or strips;

[0040] B, mixing auxiliary material: take by weighing the fresh tobacco leaf after 1000kg crushing, add 400kg biogas slurry and 2kg microbial inoculum, described microbial inoculum comprises 60% subtilis and 40% bacillus licheniformis, stir after mixing, The water content of the material after stirring is 50%;

[0041] c. Stacking fermentation: Stack the stirred mixture to a height of 1.2m and then ferment it. Turn the pile once or twice a day after the fermentation temperature reaches 50°C. Control the fermentation temperature at 52°C and the fermentation time is 8 days;

[0042] d. Magnetic separation: use a magnetic separator to remove metal impurities in the mixed material;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com