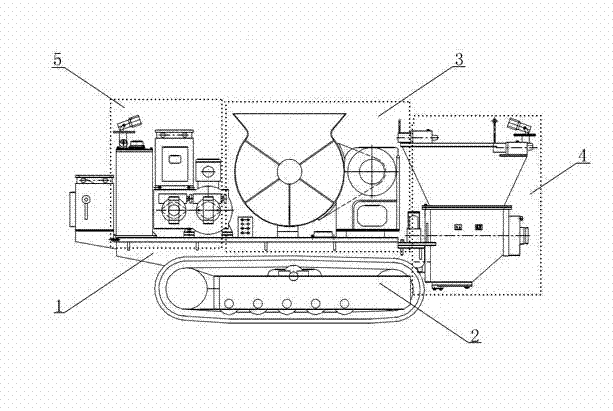

Crawler belt walking wet type concrete sprayer

A technology of concrete jetting machine and traveling mechanism, which is used in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of harsh environment, inconvenient equipment, difficult transportation of concrete, etc., to achieve stable transportation, safe use, and solve explosion-proof problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

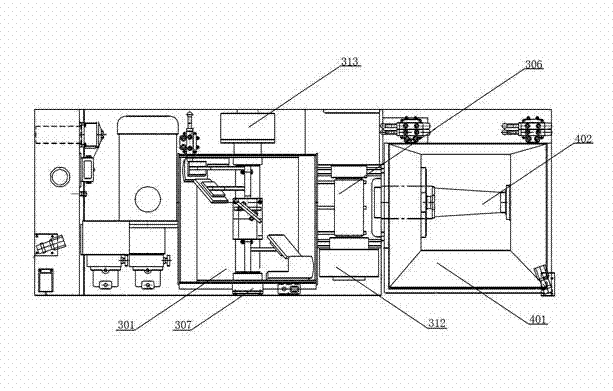

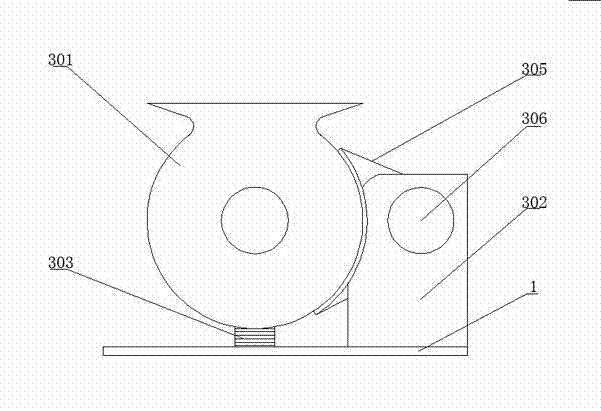

[0027] Such as figure 1 , 2 As shown: one includes a vehicle frame 1, a crawler traveling mechanism 2, a stirring and turning mechanism 3, a pumping mechanism 4 and a hydraulic system 5; the crawler traveling mechanism 2 is arranged on both sides of the vehicle frame 1, and the hydraulic pump of the hydraulic system 5 passes through The oil circuit drives the left and right traveling motors of the crawler walking mechanism 2, and the left and right traveling motors drive the driving wheels to rotate through the reducer to realize the walking of the whole vehicle; the pumping mechanism 4 is set at one end of the frame 1, and the stirring and turning mechanism 3 is set On the frame 1 on the side of the pumping mechanism 4, the concrete material is forcibly stirred by the stirring and turning mechanism 3, and the mixing tank 301 is turned over, so that the concrete material in the mixing tank 301 is poured into the pumping mechanism of the pumping mechanism 4. In the tank 401, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com