Polarization maintaining fiber side-pumped coupler and manufacturing method thereof

A polarization-maintaining fiber and side-pumped technology, which is applied in the field of lasers, can solve the problems of unsatisfactory industrial applications, limited number of coupling interfaces, poor coupler stability, etc., achieve high polarization extinction ratio, realize high-power coupling, and ensure structural stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

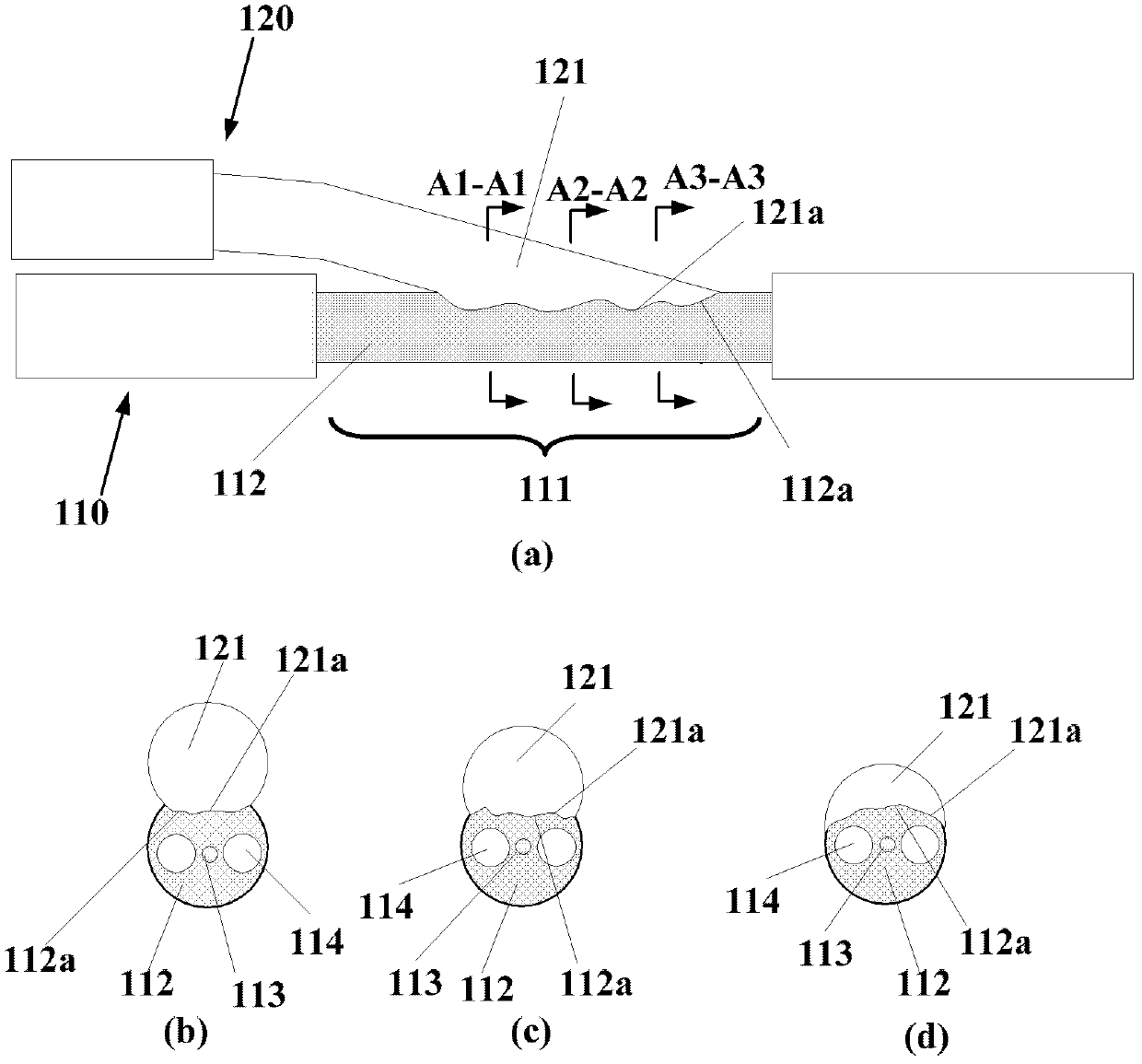

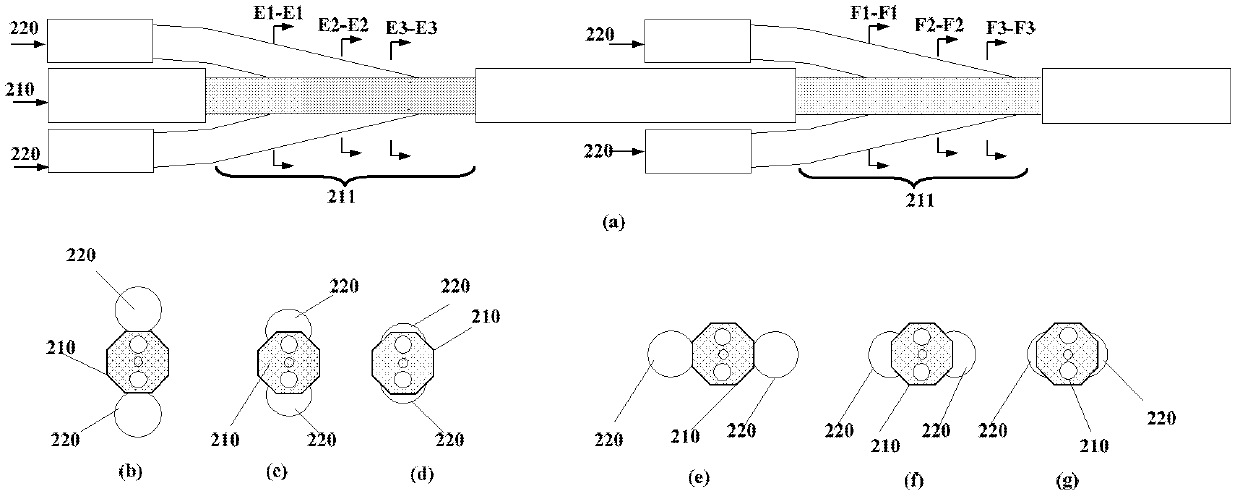

[0044] In some embodiments of the present invention, the radially outer surface 112a of the inner cladding 112 of the connecting portion 111 of the polarization maintaining main optical fiber 110 is the original surface of the inner cladding that has not been processed; in other embodiments of the present invention, the The radially outer surface 112a of the inner cladding 112 of the connecting portion 111 of the polarization maintaining main optical fiber 110 is a pretreated flat or uneven surface (such as figure 1 a-d).

[0045] In this embodiment, the number of pumps that the coupler can pump is determined by the diameter D1 of the inner cladding of the polarization-maintaining main fiber 110 and the diameter D2 of the pumping fiber 120, that is, the number of pumping fibers 120 is less than or equal to (The axis position of the polarization-maintaining main fiber is the center of the circle, and the diameter is D 1 +D 2 The circumference of the circle, divided by the di...

Embodiment 2

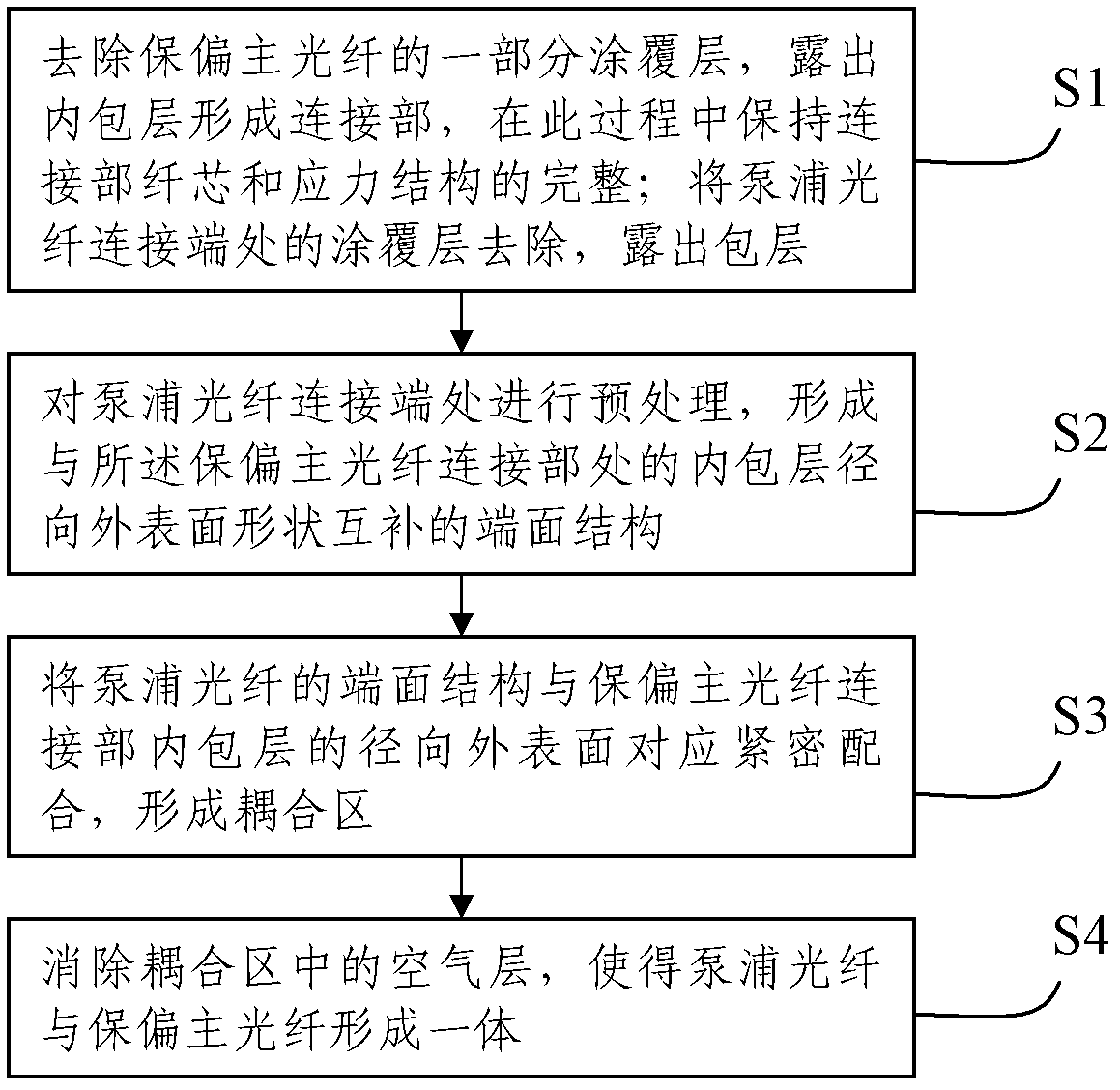

[0051] S1: Remove part of the coating layer of the polarization maintaining main fiber to expose the inner cladding to form the connection part, and keep the core and stress structure of the connection part intact during the process; remove the coating layer at the connection end of the pump fiber to expose the cladding Floor;

[0052] S2: Perform pretreatment on the connection end of the pump fiber to form an end surface structure complementary to the shape of the inner cladding radially outer surface at the connection part of the polarization-maintaining main fiber; wherein, the pretreatment method of the pump fiber is high temperature heating Force treatment, chemical etching, mechanical polishing, laser etching or ion beam etching;

[0053] S3: The end face structure of the pump fiber is matched closely with the radially outer surface of the inner cladding of the connection part of the polarization-maintaining main fiber to form a coupling region;

[0054] S4: Eliminate t...

Embodiment 3

[0059] Embodiment four:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com