Reinforced absorbable multi-layered fabric for hemostatic applications

一种吸收性、织物的技术,应用在吸收性多层止血器领域,能够解决没有描述出或提出具有止血功能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Double layer matrix of example 1-PGLA

[0023] Poly(glycolide-lactide) copolymer (PGLA, 90 mol / 10 mol) was melt spun into PGLA copolymer fibers. The multifilament yarns from PGLA copolymer fibers were consolidated, crimped, and cut into staple fibers having a length of 2.0 inches. The staple fibers were carded to produce a nonwoven batt, which was then pressed to a thickness of about 1.0 mm and a density of about 60 mg / cc. A second nonwoven batt was prepared by a similar procedure, which was then pressed to a thickness of about 1.0 mm and a density of about 120 mg / cc. Two nonwovens with densities of 60 mg / cc and 120 mg / cc were then needle punched into each other to fix the nonwoven bilayer matrix.

example 2

[0024] Example 2 Double layer matrix for hemostasis in spleen model

[0025] A mild to moderate bleeding model was prepared by making an incision 15 mm long and 3 mm deep in the pig spleen. The bilayer matrix as described in Example 1 was then applied to the surgical site and packed for two minutes. The haemostatic effect was checked within 30 seconds after two minutes of tamponade. If no self-bleeding was observed within 30 seconds, the time to hemostasis was recorded. If self-bleeding is observed, pack for an additional 30 seconds until hemostasis is achieved or until the test period reaches ten minutes (this is defined as hemostatic failure). Three test samples measuring 2.5 x 4.0 cm were cut from the bilayer matrix prepared according to Example 1, and all three test samples achieved hemostasis within 5.62 ± 0.76 minutes (Table 1).

[0026] Table 1. Hemostasis of PGLA bilayer matrix in spleen model

[0027] Sample serial number

example 3

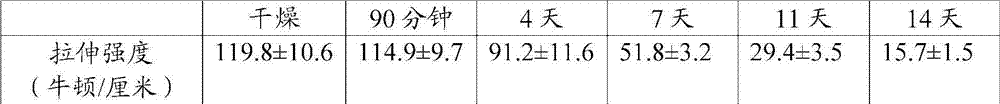

[0029] In vitro tests were used to characterize the mechanical properties of the bilayer matrices prepared according to Example 1. Cut the bilayer matrix into strips (approximately 3 / 8 inch wide by 2 inches long). The tensile strength of the bilayer matrix was then evaluated using an Instron tensile tester under dry and wet conditions. Under wet conditions, strips were placed in conical tubes containing PBS buffer at pH 7.4 at 37°C. The tensile strength of the strips was then measured at 90 minutes, 4 days, 7 days, 11 days and 14 days. The measured values of the tensile strength of the tapes of the bilayer matrix are shown in Table 2.

[0030] Table 2. Tensile Strength of Bilayer Substrates in Dry and Wet Conditions

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com