Hydraulic control flexible automatic debristling machine for pig slaughtering

A shaved, flexible technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

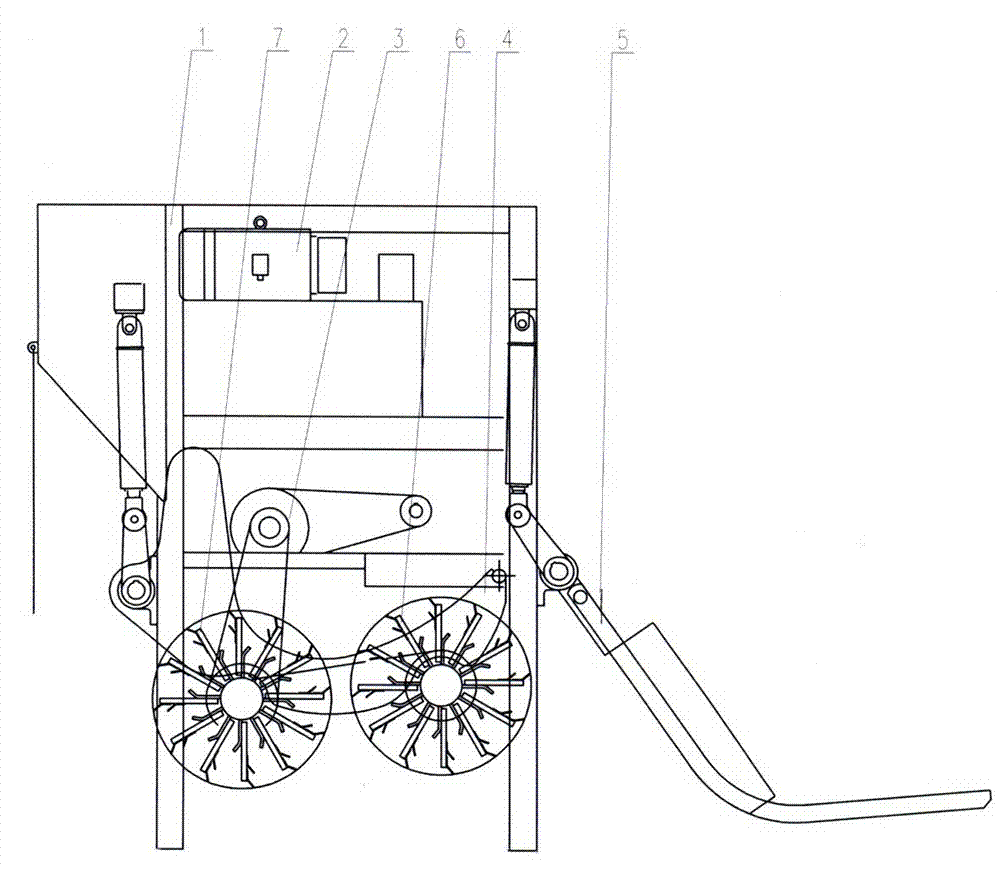

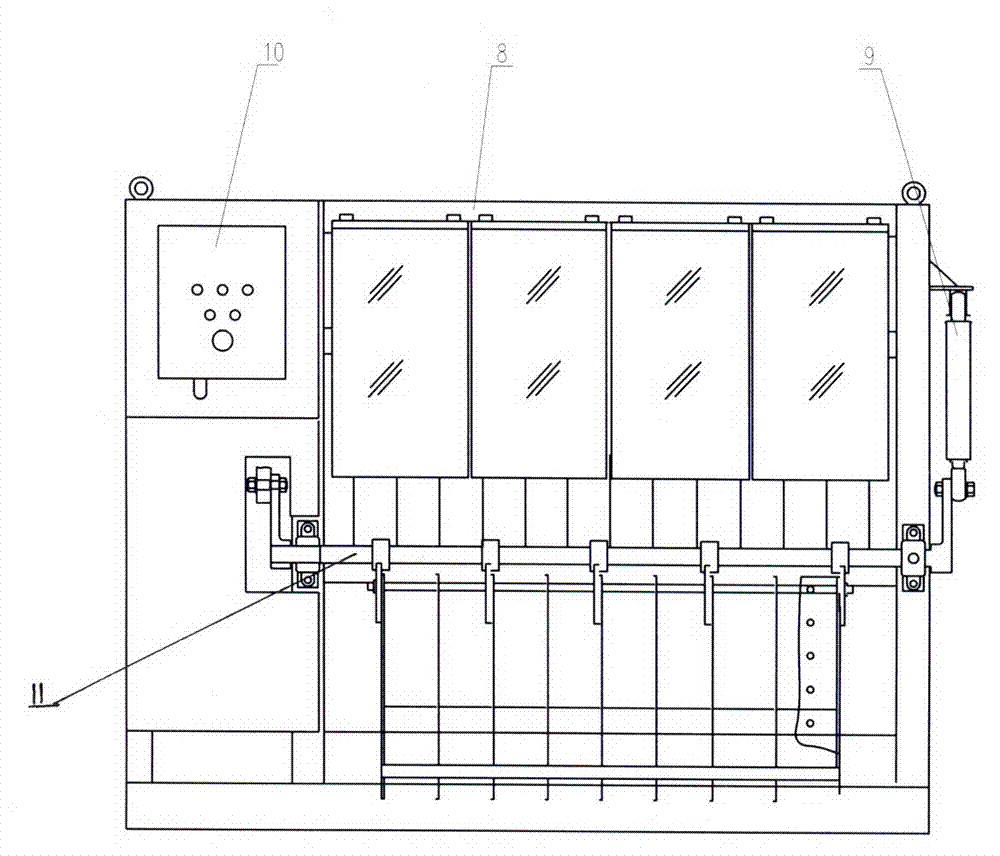

[0010] refer to figure 1 , 2 , pig slaughtering hydraulic control flexible automatic shaving machine of the present invention, it is made of frame 1, anti-moisture motor 2, chain sprocket 3, U-shaped fence 4, rake 5, front soft shaving roller 6, rear soft type Composed of shaving roller 7, spraying water device 8, hydraulic device 9, electric control box 10 and connecting rod shaft 11, anti-moisture motor 2, chain sprocket 3, U-shaped fence 4, rake 5 are respectively arranged on the frame 1 , front soft shaving roller 6, rear soft shaving roller 7, spray water device 8, hydraulic device 9, electrical control box 10 and connecting rod shaft 11, composed of six-pole low-speed moisture-proof motor 2, oil pump, solenoid valve Group, fuel tank, cooling device, oil pipe, hydraulic oil cylinder and connecting rod shaft 11 constitute hydraulic device 9, and sleeve roller chain is sleeved on chain sprocket 3 and rear soft planing roller 7, and U-shaped fence 4 is surrounded by multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com