Production process of soy and soy

A production process and a technology of too oil, applied in the production process of too oil and the field of too oil, can solve the problem of insufficient umami of soy sauce, etc., and achieve the effect of increasing the content of amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

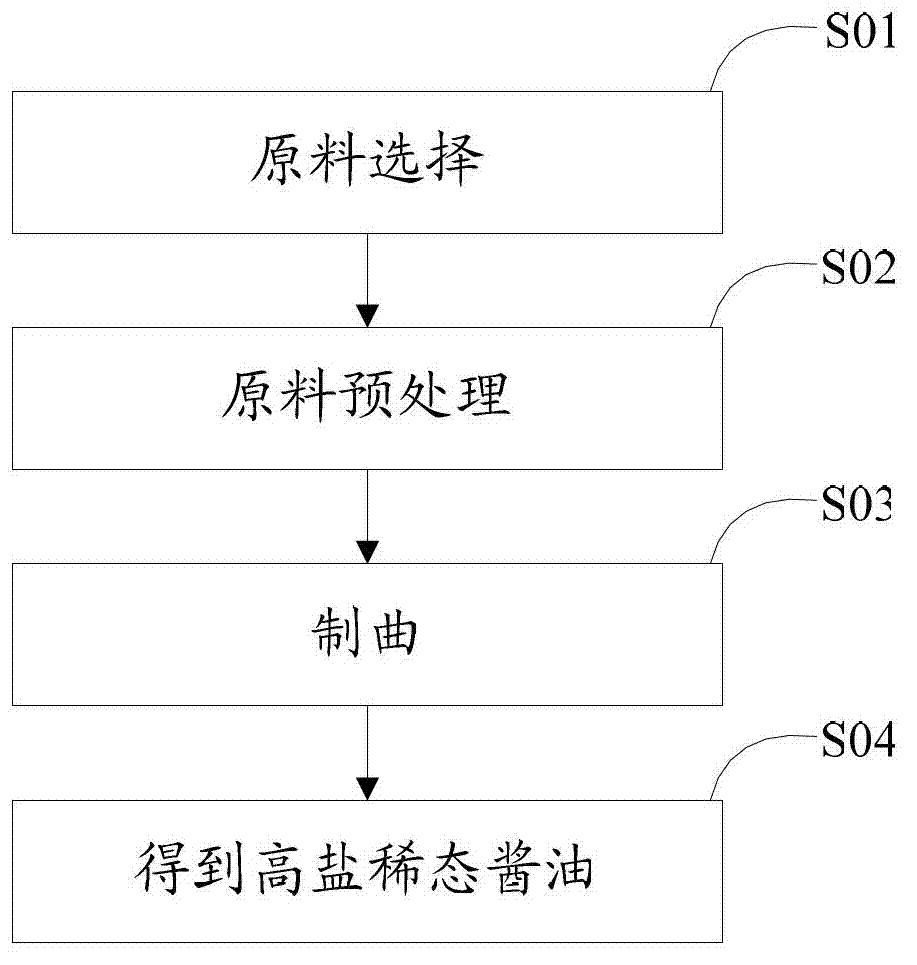

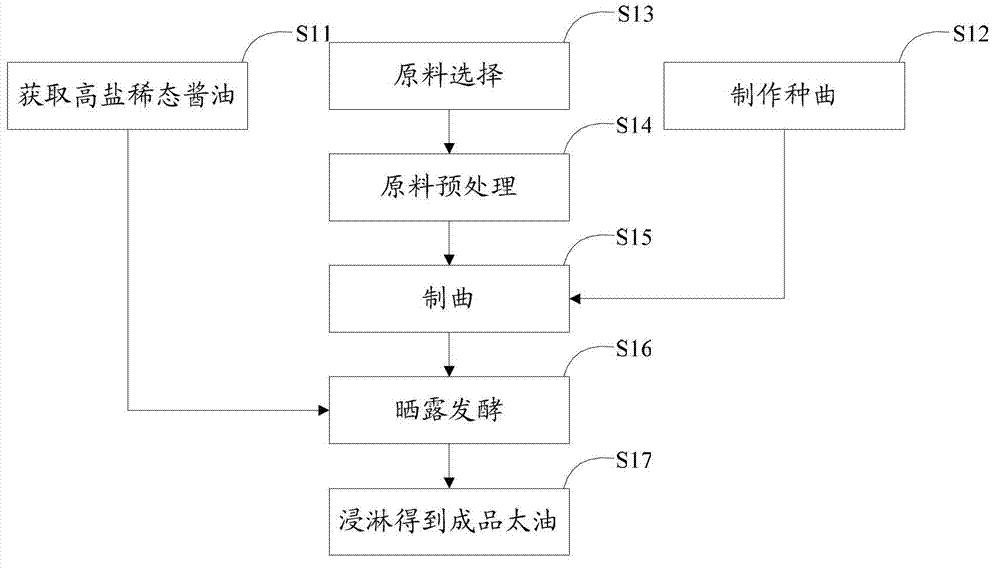

[0022] Embodiment 1. In the present embodiment, high-salt dilute soy sauce is used as crude oil, see figure 2 As shown, including the following process flow:

[0023] S11. Obtain high-salt dilute soy sauce as crude oil, and jump to step S16.

[0024] Specifically, the high-salt dilute soy sauce can be brewed through the existing technology, or the existing high-salt dilute soy sauce can be purchased.

[0025] S12. Make a kind of song, and jump to step S15.

[0026] Specifically include: Sterilization of the music room and the music plaque: rinse the music chamber and the music plaque with tap water, and steam sterilize it for later use. The raw materials for seed koji can be bran, soybean meal and water, and their mass ratios are (85~95):(5~15):(110~130). The raw material treatment of seed koji is to mix the raw materials of seed koji thoroughly, steam them under normal pressure for 50-70 minutes, simmer for 20-40 minutes, sift them out of the pot and move them to the mixi...

Embodiment 2

[0037] Embodiment 2. In the present embodiment, high-salt dilute soy sauce and sweet oil are mixed in a certain proportion as crude oil. The specific content is basically the same as the above-mentioned Example 1, except that in the dew-dew fermentation step, the mixed oil with a mass of 2 to 2.5 times the quality of the finished koji (including but not limited to 2 to 2.5 times, other times can also be implemented, All should be within the scope of protection of the present invention), exposed to the sun and fermented for more than six months.

[0038] It should be noted that the taste of the Taiyou finished product obtained in this embodiment is different from that in Example 1; furthermore, through the adjustment of the above proportions, the taste of the Taiyou finished product in this embodiment can be fine-tuned accordingly. Therefore, it can meet the needs of various consumers.

Embodiment 3

[0039] Embodiment three, the present embodiment continues embodiment one, for the convenience of explanation, the Taiyou brewed in embodiment one is called the first round of Taiyou. In this embodiment, the first round of Taiyou is used as the crude oil, and the sun-dew fermentation step and soaking step of the present invention are operated again, that is, in the second sun-dew fermentation process, the quality of the koji 2~ 2.5 times the first round of too oil (including but not limited to 2~2.5 times, other times can also be implemented, all should be within the protection scope of the present invention), and then exposed and fermented for more than six months to achieve the second set wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com