Process method for brewing Shanxi mature vinegar from multigrain multi-microbe full-distiller's-yeast raw materials

A process method and a technology for aged mature vinegar, which are applied in the field of brewing Shanxi aged mature vinegar with multi-grain, multi-micro and whole koji raw materials, can solve the problems of blank and do not involve a variety of miscellaneous grain vinegar-making methods, and achieve increased decomposition, reduced protein precipitation, and taste. soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific examples.

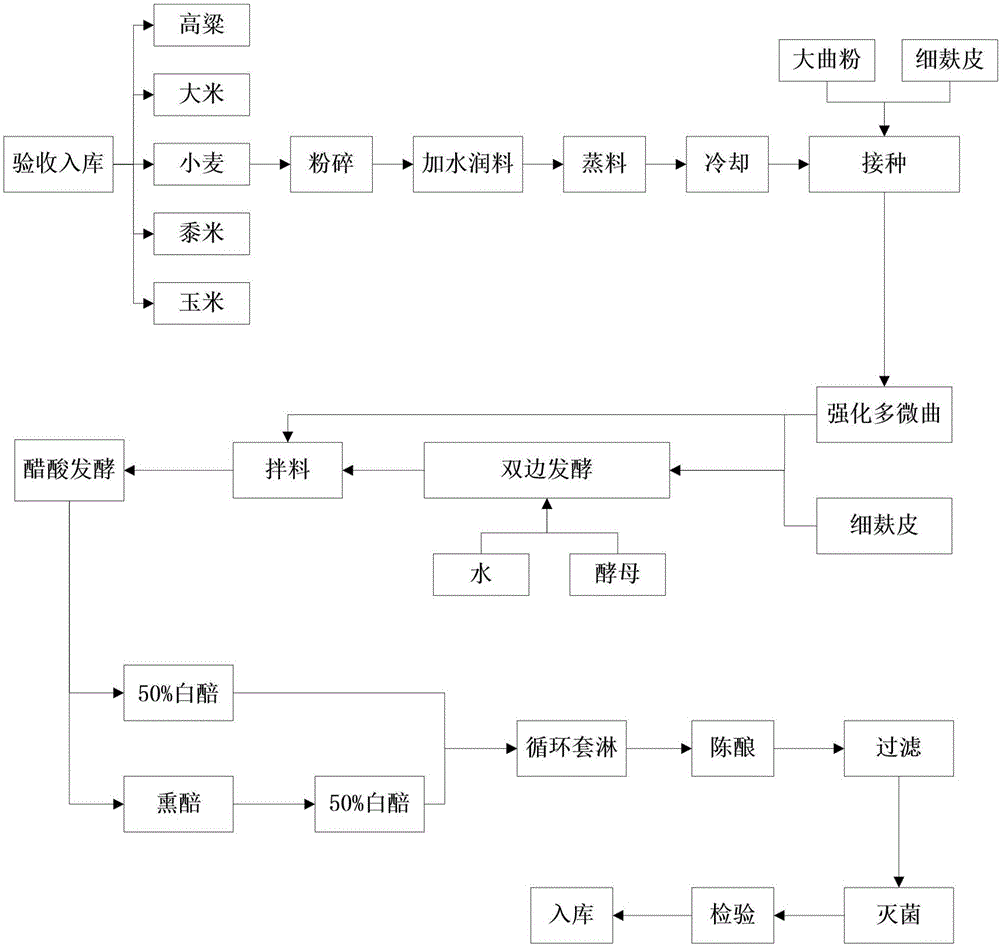

[0034] A kind of multi-grain, multi-micro and whole-curd raw material brewing process method of Shanxi mature vinegar comprises the following steps, and the technological process is as follows: figure 1 Shown:

[0035] Step 1, raw material crushing

[0036] Select high-quality, impurity-free and mildew-free sorghum, rice, wheat, millet, and corn and grind them into 4-6-8 petals for later use; the ratio of raw grains is: 50% sorghum, 20% rice, 10% wheat, and 10% millet. 10%, corn 10%, the starch content of selected raw materials is required, sorghum ≥ 65%, rice ≥ 65%, wheat ≥ 60%, millet ≥ 55%, corn ≥ 65%;

[0037] Step 2, steaming

[0038] Mix the sorghum, rice, wheat, millet, and corn crushed into 4-6-8 petals evenly, and moisten the materials with warm water at 40°C for 12 hours according to the ratio of 5:2:1:1:1. Without white heart, the amount of water added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com