Coix seed beverage and preparation method thereof

A technology of barley and beverages, which is applied in the direction of food science, etc., can solve the problems of untreated, etc., and achieve the effect of pure and natural sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Screening: the barley grains are required to be plump, white in color, free from moths and mildew, completely shelled, and impurities such as residual shells and sand particles removed;

[0031] (2) Cleaning: Wash the screened barley with water to further remove dust and small impurities, and drain the water;

[0032] (3) Baking: Dilute the barley on the baking tray and put it in the oven to bake. The upper and lower heat is 150°C, turn it from time to time, bake until the barley is light yellow, take out the cooled barley and put it in an electric grinder to grind. Pass through 150 mesh sieve;

[0033] (4) Gelatinization: the ratio of material to water is 1g:8ml, heat to 60-70°C to gelatinize the barley powder;

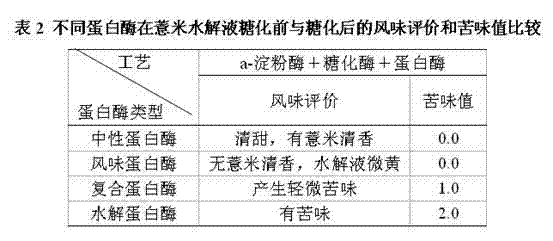

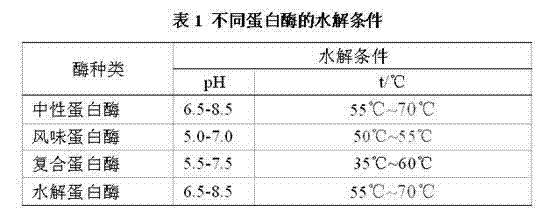

[0034] (5) Enzymatic hydrolysis: add a medium-temperature α-amylase with an enzyme activity of ≥3000U / mL at 70°C to liquefy for 30 minutes. U / mL high-efficiency liquid glucoamylase saccharification for 60 minutes, the dosage of high-efficiency liquid glu...

Embodiment 2

[0040] (1) Screening: the barley grains are required to be plump, white in color, free from moths and mildew, completely shelled, and impurities such as residual shells and sand particles removed;

[0041] (2) Cleaning: Wash the screened barley with water to further remove dust and small impurities, and drain the water;

[0042] (3) Baking: Dilute the barley on the baking tray and put it in the oven to bake. The upper and lower heat is 170°C, turn it from time to time, bake until the barley is light yellow, take out the cooled barley and put it in an electric grinder to grind. Pass through 200 mesh sieve;

[0043] (4) Gelatinization: the ratio of material to water is 1g: 10ml, heat to gelatinize barley powder;

[0044] (5) Enzymatic hydrolysis: add a medium-temperature α-amylase with an enzyme activity of ≥3000U / mL at 75°C to liquefy for 35 minutes. U / mL high-efficiency liquid glucoamylase saccharification for 65 minutes, the dosage of high-efficiency liquid glucoamylase is ...

Embodiment 3

[0049] (1) Screening: the barley grains are required to be plump, white in color, free from moths and mildew, completely shelled, and impurities such as residual shells and sand particles removed;

[0050] (2) Cleaning: Wash the screened barley with water to further remove dust and small impurities, and drain the water;

[0051] (3) Baking: Dilute the barley on the baking tray and put it in the oven to bake. The upper and lower heat is 120°C, turn it from time to time, bake until the barley is light yellow, take out the cooled barley and put it in an electric grinder to grind. Pass through 200 mesh sieve;

[0052] (4) Gelatinization: the ratio of material to water is 1g: 6ml, heat to gelatinize the barley powder;

[0053] (5) Enzymatic hydrolysis: add a medium-temperature α-amylase with an enzyme activity of ≥3000U / mL at 65°C for liquefaction for 25 minutes, and the dosage of the medium-temperature α-amylase is 2.0mL / kg dry powder; cool down to 60°C and add an enzyme with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com