Exhaust gas purifying device

A technology of exhaust gas purification device and catalytic device, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as damage to the atmospheric environment, and achieve the effect of good purification effect, fast and efficient treatment of exhaust gas, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

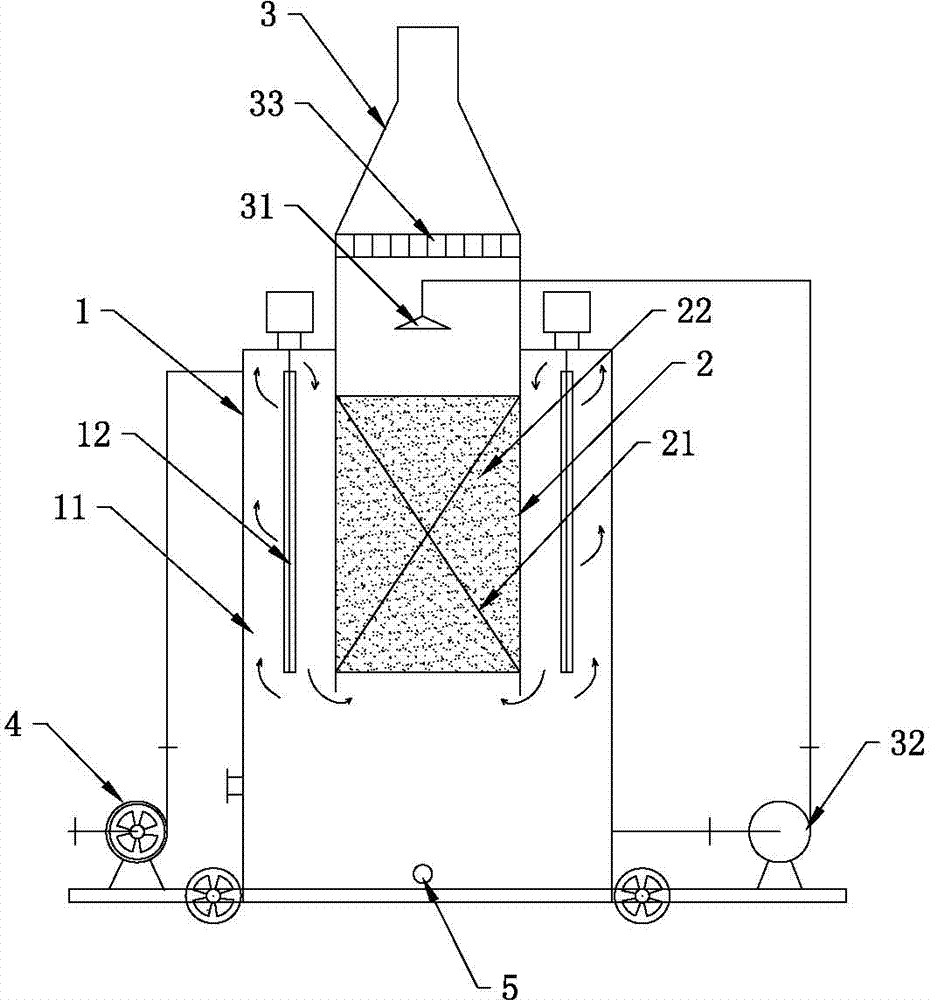

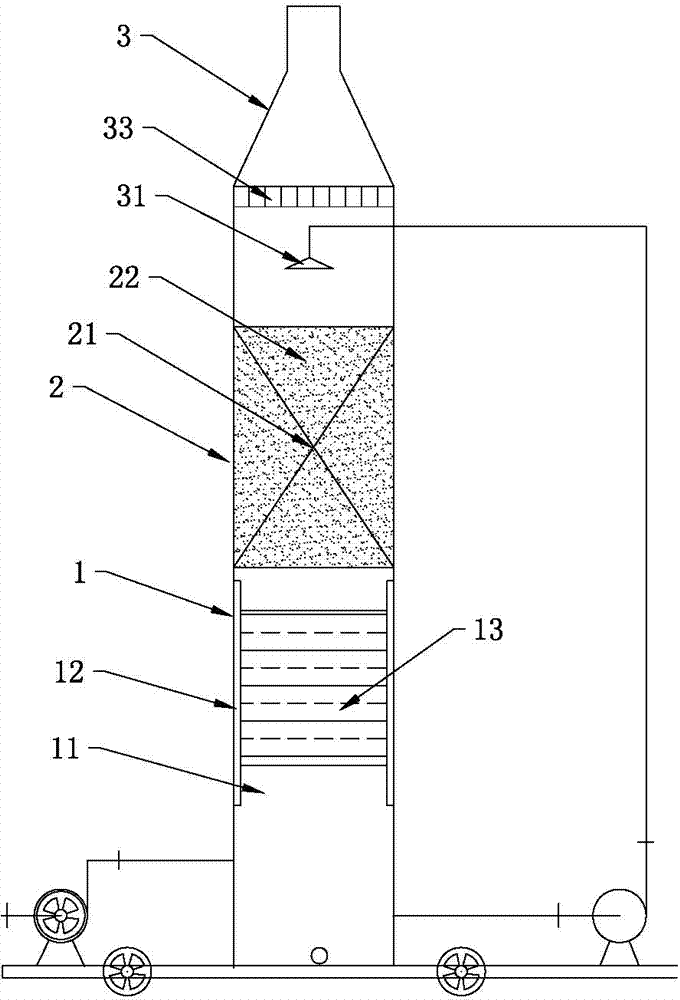

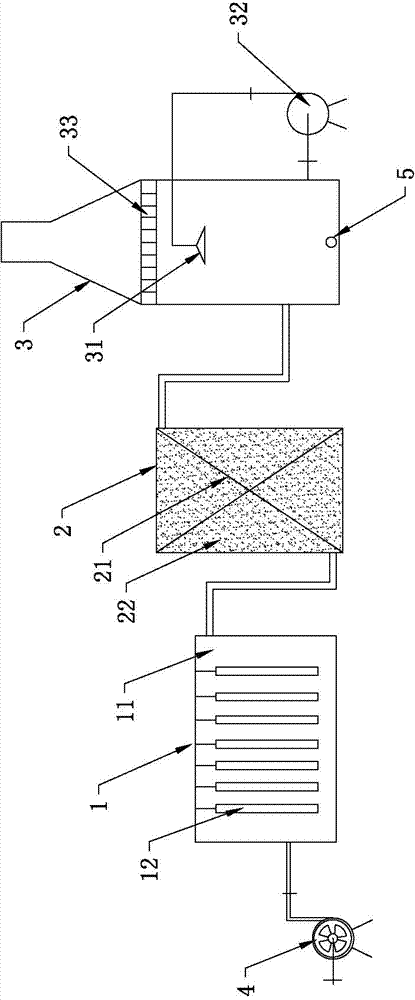

[0031] An exhaust gas purification device, such as figure 1 As shown, including ultraviolet catalytic device 1, ozone treatment device 2 and spray device 3, in the present embodiment, ultraviolet catalytic device 1, ozone treatment device 2 and spray device 3 are all cylindrically arranged, and spray device 3 It is arranged above the ozone treatment device 2 and forms an assembly along the longitudinal direction. The assembly is arranged in the ultraviolet catalytic device 1 and the spray device 3 extends out of the ultraviolet catalytic device 1. The lower end of the ozone treatment device 2 and the ultraviolet catalytic device 1 The gas outlet is connected, and the lower end of the spray device 3 is connected with the upper end of the ozone treatment device 2 .

[0032] In this embodiment, an ultraviolet photolysis chamber 11 for decomposing components in the ultraviolet photocatalytic exhaust gas is formed between the inner wall of the ultraviolet catalytic device 1 and the...

Embodiment 2

[0037] The difference between the exhaust gas purification device of this embodiment and that of Embodiment 1 is that the photocatalyst of this embodiment is a composite catalyst containing transition metal oxides. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0039] The difference between the exhaust gas purification device of this embodiment and that of Embodiment 1 is that the photocatalyst is a photocatalyst containing titanium oxide. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com