Counter flow type vertical flow artificial wetland system

A constructed wetland system and constructed wetland technology, applied in the field of counter-flow vertical flow constructed wetland system, can solve the problems of blockage, large floor space, unsuitable pollution concentration sewage treatment, etc. The effect of graded effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

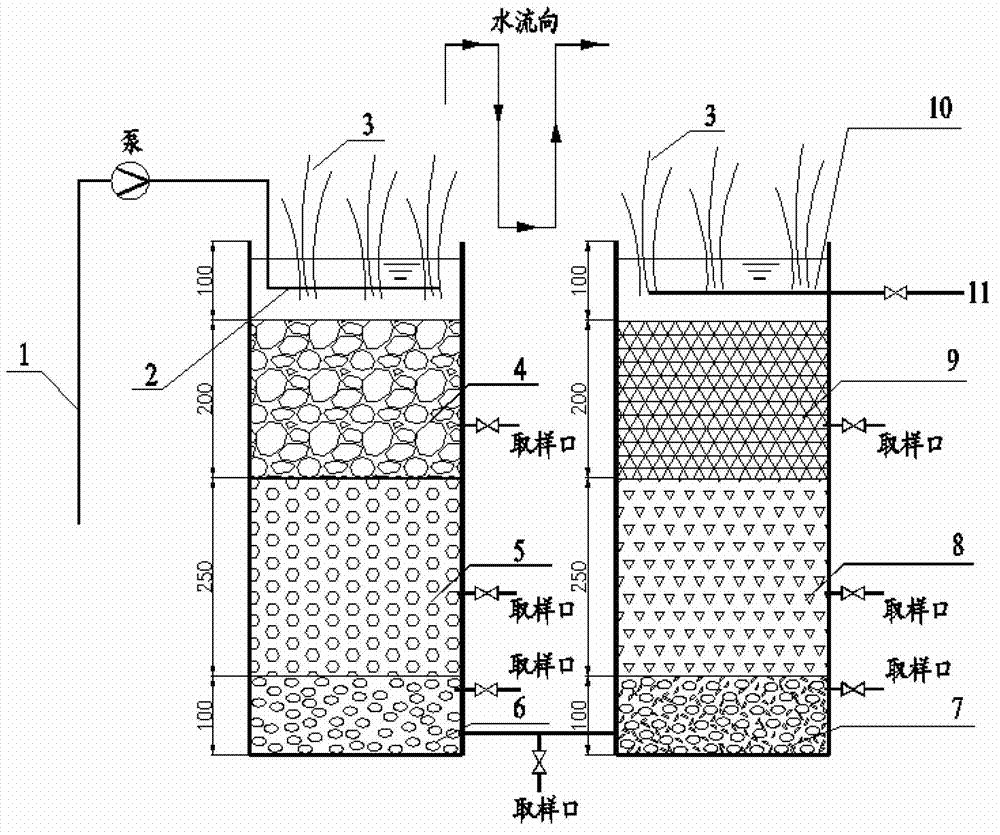

[0020] Such as figure 1 As shown, the water inlet of the countercurrent vertical flow constructed wetland is provided with a water inlet pipe 1 and a water distribution area 2, and the sewage passes through the water distribution system so that the water flow is evenly distributed in the packing layer;

[0021] Downward flow wetland unit composite packing bed, the bed body from top to bottom is gravel 4, zeolite 5, pebble 6;

[0022] Upward flow wetland unit composite packing bed, the bed body from bottom to top is pebble + rice husk 7, steel slag 8, limestone 9;

[0023] Aquatic plants 3 with strong sewage purification ability and suitable for local environmental conditions are planted on the upper layer of the wetland, such as reeds.

[0024] The water outlet of the upflow constructed wetland unit is provided with a water collection area 10 and a water outlet pipe 11, and the sewage is discharged through overflow.

[0025] The working process of the present invention's sew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com