Preparation method of super-hydrophilic thin film based on glass surface

A glass surface and super-hydrophilic technology, which is applied in the field of super-hydrophilic films, can solve problems such as difficult to achieve large-area surface preparation, hydrophilicity cannot be maintained for a long time, and films are not wear-resistant, so as to achieve firm adhesion , small investment, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

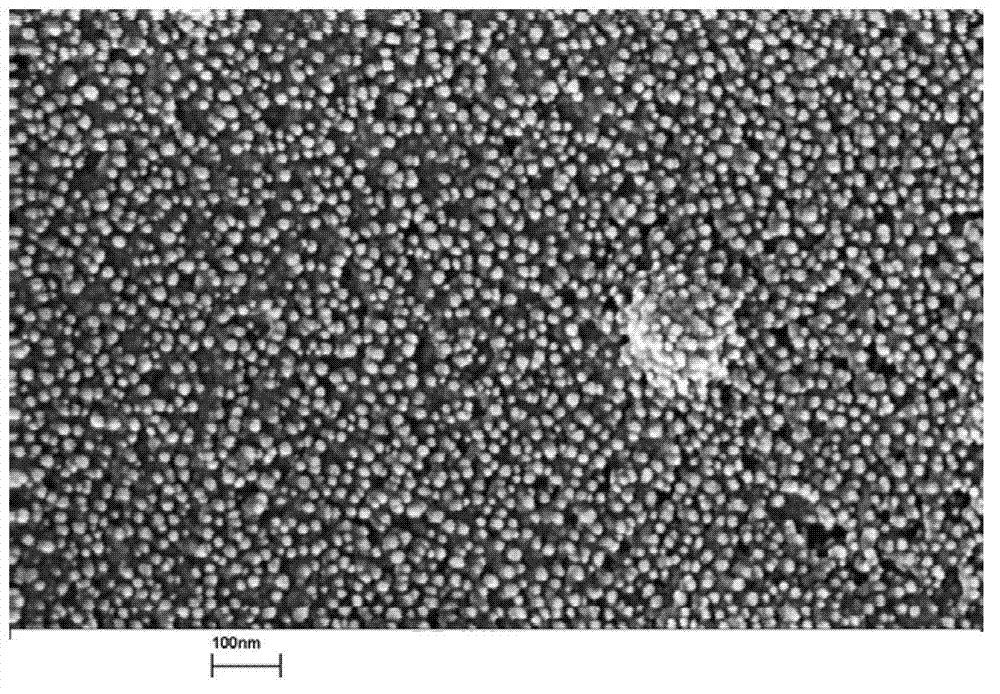

Image

Examples

Embodiment 1

[0023] Take 5ml of tetraethyl orthosilicate, 10ml of ethanol, and 2ml of deionized water, mix and stir for 5 minutes, then add 10ml of hydrochloric acid with a mass fraction of 5% dropwise, stir magnetically for 5 minutes, then add dilute ammonia water dropwise until the pH of the sol is 3, and continue stirring After 0.5h, the obtained SiO was diluted with ethanol solution at a volume ratio of 1:1 2 Sol. dilute SiO 2 5% PEG600 was added to the sol, ultrasonically oscillated, and then the mixed solution was used to wipe and coat the glass surface, followed by sintering at 450°C for 1h.

Embodiment 2

[0025] Take 5.5ml of tetraethyl orthosilicate, 10ml of ethanol, and 2.5ml of deionized water and mix and stir for 5 minutes, then add dropwise 10ml of hydrochloric acid with a mass fraction of 5.5%, magnetically stir for 5 minutes, and then add dropwise dilute ammonia water until the pH of the sol is 4. After continuing to stir for 0.5 h, dilute the SiO obtained by volume ratio 1:2 with ethanol solution 2 Sol. dilute SiO 2 10% PEG600 was added to the sol, ultrasonically oscillated, and then the mixed solution was used to wipe and coat the glass surface, followed by sintering at 490°C for 2h.

Embodiment 3

[0027] Take 6ml of tetraethyl orthosilicate, 15ml of ethanol, and 3ml of deionized water, mix and stir for 10 minutes, then add dropwise 15ml of hydrochloric acid with a mass fraction of 6%, stir magnetically for 10 minutes, then add dropwise dilute ammonia water until the pH of the sol is 5, and continue stirring After 1 h, the obtained SiO was diluted with ethanol solution at a volume ratio of 1:3 2 Sol. dilute SiO 2 15% PEG600 was added to the sol, ultrasonically oscillated, and then the mixed solution was used to wipe and coat the glass surface, followed by sintering at 520°C for 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com