Preparation method for carbon slider used for assembling pantograph of electric locomotive

A technology for electric locomotives and carbon sliding plates is applied in the field of preparation of carbon sliding plates to achieve the effects of simple operation of the preparation process, good wear resistance and full utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

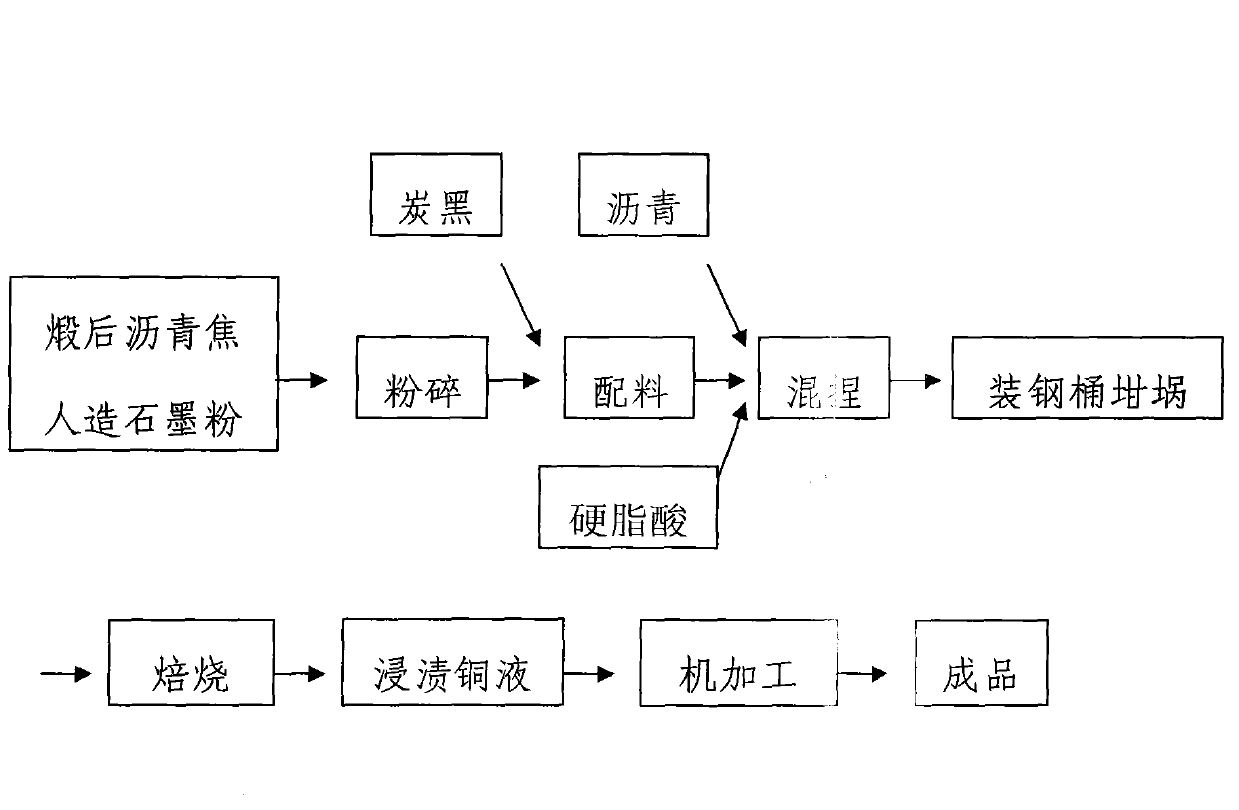

Method used

Image

Examples

Embodiment 1

[0020] Product preparation method:

[0021] Mix 625kg of calcined pitch coke particles with a particle size of 1-0mm, 100kg of artificial graphite particles with a particle size of 0.5-0mm, and 30kg of N330 carbon black with 240kg of molten pitch, add 5kg of stearic acid, and then use an extruder under a pressure of 11MPa Extruded into a 30×60×880mm square bar, roasted at 850°C for 300 hours, and then impregnated with 400kg of molten copper liquid for 2 hours, the weight of the copper-impregnated carbon slide is 1350kg. Product physical and chemical indicators:

[0022] Standard sizes 30×60×880mm Bulk density 2.57g / cm3 Resistivity 7.52μΩm

[0023] Flexural strength 87MPa Compressive strength 170MPa Impact toughness Not broken Shore hardness 82 wear height 4.7

Embodiment 2

[0025] Product preparation method:

[0026] Mix 630kg of calcined pitch coke particles with a particle size of 1-0mm, 85kg of artificial graphite particles with a particle size of 0.5-0mm, and 40kg of N330 carbon black with 235kg of molten pitch, add 10kg of stearic acid, and then use an extruder under a pressure of 9MPa Extruded into 30×60×1000mm square bars, roasted at 850°C for 320 hours, each cut into 3 sections, and then impregnated with 400kg of molten copper liquid for 2 hours, the weight of the copper-impregnated carbon slide is 1300kg. Product physical and chemical indicators:

[0027] Standard sizes 30×60×305mm Bulk density 2.51g / cm3 Resistivity 8.52μΩm Flexural strength 92MPa Compressive strength 183 MPa Impact toughness Not broken Shore hardness 85 wear height 4.3

Embodiment 3

[0029] Product preparation method:

[0030] Mix 630kg of calcined pitch coke particles with a particle size of 1-0mm, 90kg of artificial graphite particles with a particle size of 0.5-0mm, and 35kg of N330 carbon black with 235kg of molten pitch, add 10kg of stearic acid, and then use an extruder under a pressure of 14MPa Extruded into 24×30×650mm square bars, roasted at 850°C for 280 hours, and then impregnated with 400kg of molten copper liquid for 2 hours, the weight of the copper-impregnated carbon slide is 1360kg. Product physical and chemical indicators:

[0031] Standard sizes 24×30×600mm Bulk density 2.35g / cm3 Resistivity 7.82μΩm Flexural strength 87MPa Compressive strength 210MPa

[0032] Impact toughness Not broken Shore hardness 85 wear height 4.3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com