Method for synthesizing aluminum citrate cross-linking agent in low carbon solvent

A technology of aluminum citrate and cross-linking agent, applied in chemical instruments and methods, carboxylate preparation, drilling composition, etc., can solve low oil production rate, water flooding and polymer flooding are difficult to achieve high Problems such as recovery rate, to achieve the effect of stable gelation performance and controllable gelation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

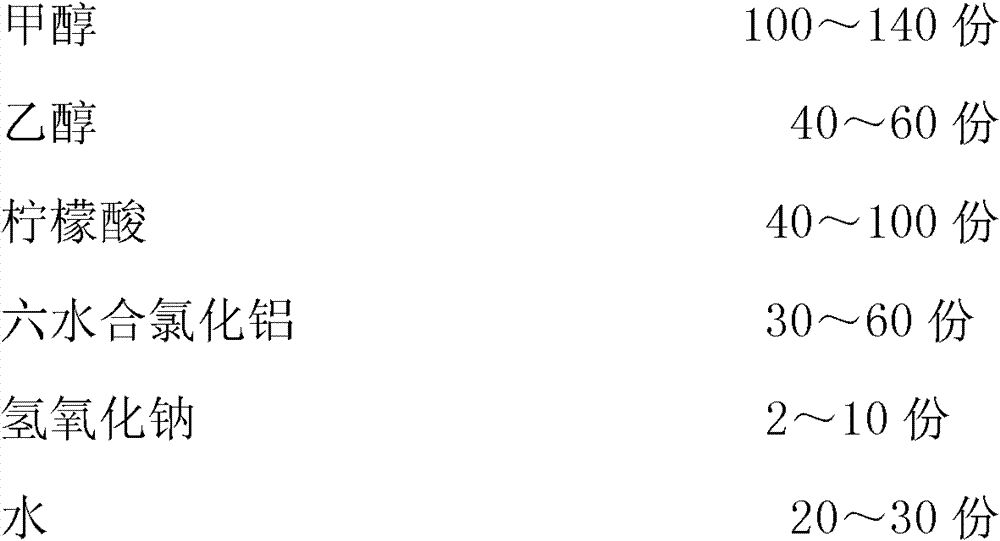

[0023] (1) The proportioning of chemical raw materials is by weight:

[0024]

[0025] (2) The chemical reaction process steps are:

[0026] Under normal pressure, first mix methanol and ethanol in proportion, add citric acid to dissolve completely, add aluminum chloride hexahydrate under stirring, raise the temperature to 50°C for 4 hours, slowly add sodium hydroxide solution dropwise, adjust the pH value In 7.5, finally add the remaining component water and stir evenly to obtain the aluminum citrate crosslinking agent.

Embodiment 2

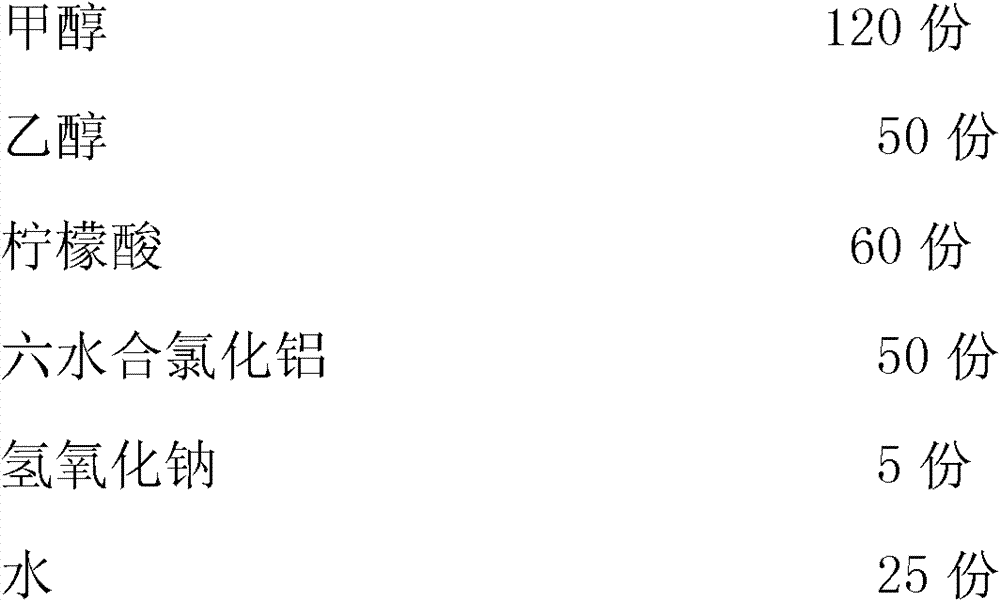

[0028] (1) The proportioning of chemical raw materials by weight is:

[0029]

[0030]

[0031] (2) The chemical reaction process steps are:

[0032] Under normal pressure, first mix methanol and ethanol in proportion, add citric acid to dissolve completely, add aluminum chloride hexahydrate under stirring, raise the temperature to 40°C for 4 hours, slowly add sodium hydroxide solution dropwise, adjust the pH value In 5.5, finally add the remaining component water and stir evenly to obtain the aluminum citrate crosslinking agent.

Embodiment 3

[0034] (1) The proportioning of chemical raw materials by weight is:

[0035]

[0036] (2) The chemical reaction process steps are:

[0037] Under normal pressure, first mix methanol and ethanol in proportion, add citric acid to dissolve completely, add aluminum chloride hexahydrate under stirring, raise the temperature to 80°C for 4 hours, slowly add sodium hydroxide solution dropwise, adjust the pH value In 8.5, finally add the remaining component water and stir evenly to obtain the aluminum citrate crosslinking agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com