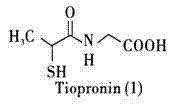

Method for preparing tiopronin

A technology of tiopronin and sodium disulfide, applied in the field of medicine, can solve problems such as low yield of tiopronin, unfavorable treatment of three wastes, and increased reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

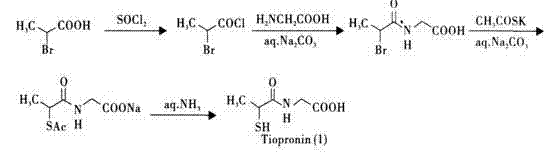

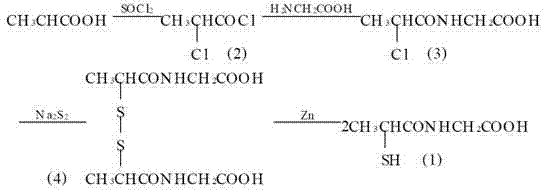

Method used

Image

Examples

Embodiment Construction

[0034] 1. Preparation of α-chloropropionyl chloride

[0035] Add 108.6 g (1 mol) of α-chloropropionic acid and 178.4 g (1.5 mol) of thionyl chloride into a 100 mL round-bottomed flask, reflux for 5 h, collect the distillate with bp 109~111°C to obtain 120.1 g of colorless liquid , the yield is 94.5%.

[0036] 2. Preparation of α-chloropropionylglycine

[0037] Add 37.4 g (0.5 mol) of glycine, 53.0 g (0.5 mol) of anhydrous sodium carbonate and 500ml of water into a 1000 mL four-necked flask, and stir to dissolve. Cool in an ice-salt bath, and add α-chloropropane dropwise under vigorous stirring Acyl chloride 63.3 g (0.5 mol), continue to stir for 3 h after addition, acidify with hydrochloric acid to pH = 1, extract with ethyl acetate, dry over anhydrous sodium sulfate, filter, concentrate the filtrate until crystals precipitate, place, filter The precipitated crystals were dried to obtain 56.1 g of small colorless needle-like crystals, with a yield of 68%, mp 104~105°C.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com