Process method for brewing ginseng vinegar by immobilized fermentation

A technology of immobilized fermentation and process method, applied in the field of ginseng vinegar brewed by immobilized fermentation, can solve the problems of weak aroma, poor stability, light color, etc., and achieve the effect of sour and refreshing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Raw material preparation: select 0.25kg of raw sun-dried ginseng, and remove traces of rust.

[0023] 2. Crushing: The raw sun-dried ginseng is crushed into powder with a pulverizer, and the particle diameter is ≤1mm.

[0024] 3. Extraction and enzymatic hydrolysis: extract raw sun-dried ginseng: water according to the material ratio of 1:12, the temperature is 85-90°C, and the time is 1-2 hours. Cool to 65-70°C, add α-amylase for enzymolysis for 1-2 hours, cool to 60-65°C, add glucoamylase for 1-2 hours, heat to 95-100°C to inactivate the enzyme.

[0025] 4. Adjustment: Add concentrated jujube juice with a sugar concentration of 60% (m / m) to the ginseng slurry, the amount added is 5% of the mass of the ginseng slurry, white granulated sugar is made into a 70% concentrated sugar solution and added until the sugar content is reached Reach 10-11%.

[0026] 5. Add yeast: Add 1‰ of high-activity Saccharomyces cerevisiae yeast, activate it as required, add it to th...

Embodiment 2

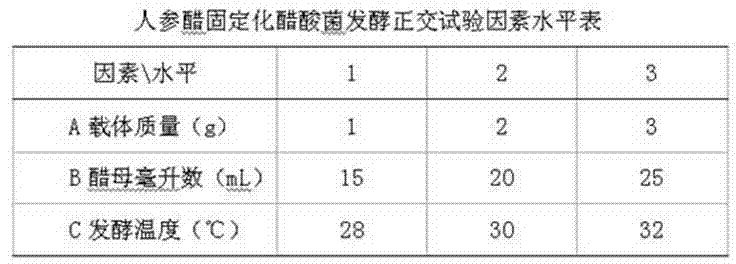

[0034] During the test, different temperatures, different slurry pH values, and different yeast additions were used to conduct orthogonal experiments to determine the optimal process flow and parameters as follows:

[0035] Process flow: ginseng→selection→cleaning→powdering→leaching→adjusting→adding yeast→alcoholic fermentation→adjusting→adding immobilized acetic acid bacteria→heat sterilization→acetic acid fermentation→heat sterilization→separation and pressing→aging→clarification→filtering→raw vinegar

[0036] Raw materials and accessories: fresh ginseng, white sugar, α-amylase, glucoamylase, brewer's active dry yeast, acetic acid bacteria, concentrated jujube juice, sawdust.

[0037] Pretreatment: When the raw material is fresh ginseng, cut into 3-5mm slices, add water three times the mass of ginseng and heat to 80°C-85°C for beating. Cool to 60°C-65°C, add 0.1%-0.2% α-amylase and 0.1-0.2% glucoamylase respectively and keep for 1-2h to completely saccharify the starch, heat...

Embodiment 3

[0045]Pretreatment: When the raw material is fresh ginseng, take 1kg of fresh ginseng and cut it into 3-5mm slices with a horizontal knife, add water three times the mass of ginseng and heat to 80°C-85°C for beating. Cool to 60°C-65°C, add 0.1%-0.2% α-amylase and 0.1-0.2% glucoamylase respectively and keep for 1-2h to completely saccharify the starch, heat to inactivate the enzyme, cool to room temperature and add sugar concentration of For 60% (m / m) concentrated jujube juice, the amount added is 5% of the juice mass, and white sugar is added to adjust the sugar content to more than 10%.

[0046] Alcoholic fermentation process parameters: fermentation temperature 17°C-20°C, the amount of Saccharomyces cerevisiae added is 1‰ of the juice quality, and the fermentation time is 7-10 days.

[0047] Production process of immobilized particles: Activate and cultivate acetic acid bacteria, insert 10-20mL 4% ginseng wine into one slant medium, and expand the culture for two generations...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com